SAFETY FIRST

WARNINGS IN THE MANUAL

WARNING

IMPORTANT

NOTE

1

Contents

Instructions will contain warnings within this manual, they will be marked with a symbol concern-

ing critical points which must be taken into consideration to prevent any possible serious bodily

injury. You are requested to read all such instructions carefully and follow them without fail.

This mark indicates instructions which must be followed in order to prevent accidents that could lead to serious

bodily injury or death.

This mark indicates instructions which must be followed to prevent any mechanical failures, breakdowns and/or

damage.

This mark indicates hints or directions that are useful in the use of this machine.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

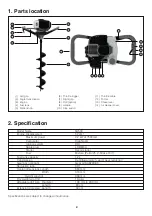

Parts location ............................................................................

Specifications ...........................................................................

Warning labels on the machine ................................................

Symbols on the machine ..........................................................

For safe operation .....................................................................

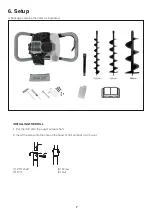

Setup ........................................................................................

Fuel ...........................................................................................

Operation ..................................................................................

Maintenance .............................................................................

Storage .....................................................................................

Troubleshooting guide ..............................................................

Disposal ....................................................................................

Spare parts ...............................................................................

Warranty ...................................................................................

2

2

3

3

4

7

8

9

10

11

12

12

12

13