B.

If there are any missing or damaged pieces or you need assistance with

assembly please contact the consumer relations department directly. Call us

before going back to the store.

STOP

STOP

STOP

STOP

Key Number:

The first two digits represent the step

number. The third digit represents the piece. Note

that if the part is used in multiple steps then the

number only reflects the first step it is used in.

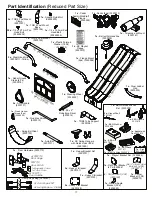

Quantity

Key Number

Part Description,

Part Size

2X 012 Post 2 x 4 x 83”

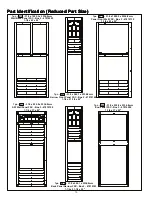

Step 1: Inventory Parts - Read This Before Starting Assembly

• Please refer to Page 6 for proper hardware assembly.

• Each step indicates which bolts and/or screws you will need for assembly, as well as

any flat washers, lock washers, t-nuts or lock nuts.

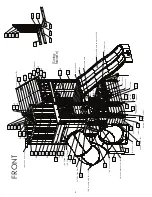

A.

This is the time for you to inventory all your hardware, wood and accessories,

referencing the parts identification sheets. This will assist you with your assembly.

• The wood pieces will have the key number stamped on the ends of the boards.

Organize the wood pieces by step, as per the key numbering system below.

CARTON I.D. STAMP: __ __ __ __ __ 14459 ___ (Box 4)

CARTON I.D. STAMP: __ __ __ __ __ 14459 ___ (Box 5)

CARTON I.D. STAMP: __ __ __ __ __ 14459 ___ (Box 6)

CARTON I.D. STAMP: __ __ __ __ __ 14459 ___ (Box 1)

CARTON I.D. STAMP: __ __ __ __ __ 14459 ___ (Box 2)

CARTON I.D. STAMP: __ __ __ __ __ 14459 ___ (Box 3)

MODEL NUMBER:

F29055E

TRACKING NUMBER (from ID Plaque):

customersupport@kidkraft.com

Online Parts Replacement:

Cedarsummitplay.com/parts-center-

warranty-claim

Customer Service:

1(800) 933-0771 or (972) 385-0100

Europe Customer Service: +31 (0)20 305 8620

europecustomerservice@kidkraft.com

EU Online Parts Replacement: parts.kidkraft.eu

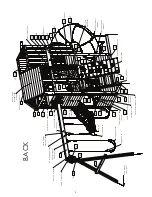

C.

Read the assembly manual completely, paying special attention to EN71 and

ASTM warnings; notes; and safety/maintenance information on pages 1 - 6.

D.

Before you discard your cartons fill out the form below.

• The carton I.D. stamp is located on the end of each carton. The tracking number is

located on the Cedar Summit ID Plaque (9320370).

• Please retain this information for future reference. You will need this information if you

contact the Consumer Relations Department.

20

Summary of Contents for Cedar Summit COPPER RIDGE PLAYSET

Page 111: ...NOTES ...