MAINTENANCE GUIDELINES

A consistent and thorough maintenance plan for each playground and independent play unit is the

most effective way to keep your playground safe. Train the right people to oversee maintenance

schedules and conduct inspections. We recommend the playground safety course offered by the

National Recreation and Parks Association. With the successful completion of the course, a participant

will earn the Certified Playground Safety Inspector (CPSI) certification, which is good for three years.

Maintenance

Maintenance reviews should be carried out in a systematic manner by trained personnel familiar with

the playground area, such as maintenance workers, playground supervisors, etc. Any damaged or

worn parts, or any other hazards identified during a review must be repaired or replaced before

allowing children to use the playground equipment.

The frequency of maintenance will be determined by several factors, such as the frequency of use,

number of children using each unit, age of children, age of equipment, the surrounding area, and

frequency and severity of inclement weather.

Maintaining your playground equipment as well as its surrounding area is essential to minimizing the

risk of injury to users, as well as maximizing your playground’s useful lifespan. We recommend the

following maintenance procedures be followed.

On a daily basis

: A responsible individual should conduct a brief visual check for structural defects,

signs of vandalism, and litter of foreign matter that needs to be removed.

On a weekly basis

: A responsible individual should complete the checklist on the following pages. Any

required repairs should be detailed on the separate maintenance report. Once the repairs are

completed, file the signed checklist and the record for future reference. A dated file and form should be

kept for each play structure at each location.

Inspection

Inspections should be carried out by a certified playground safety inspector (CPSI). Check with your

local area to find of if there are current regulations regarding playground inspections.

Audit

Audits are conducted at milestones in the life of your playground. An audit includes a full inspection as

well as a maintenance plan. Audits are recommended at the completion of the installation, a renovation

or major addition. Part of the audit will include a maintenance plan and an inspection schedule.

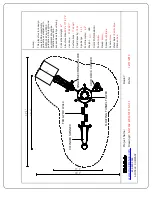

Summary of Contents for NX-1402

Page 12: ...MAINTENANCE CHECKLIST...

Page 14: ...Thank you for the opportunity to serve you...

Page 15: ......

Page 17: ...6 5 6 7 8 1 2 3 4 NX 1402 25 4 37 4 17 1 29 1...