SUPERVISION GUIDELINES

Even playgrounds that are designed, installed, and maintained in accordance with safety guidelines

and standards can still present hazards to children in the absence of adequate supervision.

The goal of playground safety is to remove hazards and minimize injury while playing, but these risks

cannot be eliminated entirely. Because all playgrounds present some challenge, and children can be

expected to use equipment in unintended ways, injuries can occur.

It is the responsibility of a playground supervisor to understand the basics of playground safety.

Supervisors should be aware that the playground equipment is designed based on the most current

CPSC guidelines. For more information on playground guidelines, go the Consumer Product Safety

Commission’s website at www.cpsc.gov.

The following are some general guidelines to follow:

Direct children to age-appropriate activities, keeping in mind that not all playground equipment is

appropriate for all children who may use the playground. The range of users encompassed by this

CPSC specification is the 5th percentile 2-year-old through the 95th percentile 12-year-old. It is

important to recognize that preschool-age children require more attentive supervision on

playground equipment than older children.

Children should not wear loose clothing, hoods, drawstrings, or jewelry while on the playground

equipment. These items could pose a strangulation/entanglement hazard.

Make sure children are wearing proper footwear.

Check for and remove unsafe modifications that are not part of the design, especially ropes tied to

equipment, before letting children play.

Look out for dangerous horseplay, such as children throwing protective surface materials, jumping

from heights, etc.

Watch for and stop children from wandering away from the play area.

Check for properly maintained protective surfacing.

Prohibit use of playground while wet. Wet equipment will not provide the necessary traction and

gripping capability. Slips or falls may occur.

Observe play patterns to note possible hazardous play and overcrowding on playground equipment.

Loose-filled Surfacing:

Surfacing should be checked regularly to ensure it has not displaced significantly, particularly in areas

of the playground most subject to displacement (heavy traffic areas such as stair entry and slide exits).

Displaced loose-fill surfacing should be raked back into proper place so that a constant depth is

maintained throughout the playground area.

Summary of Contents for NX-1402

Page 12: ...MAINTENANCE CHECKLIST...

Page 14: ...Thank you for the opportunity to serve you...

Page 15: ......

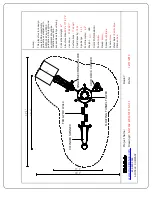

Page 17: ...6 5 6 7 8 1 2 3 4 NX 1402 25 4 37 4 17 1 29 1...