17

Installation

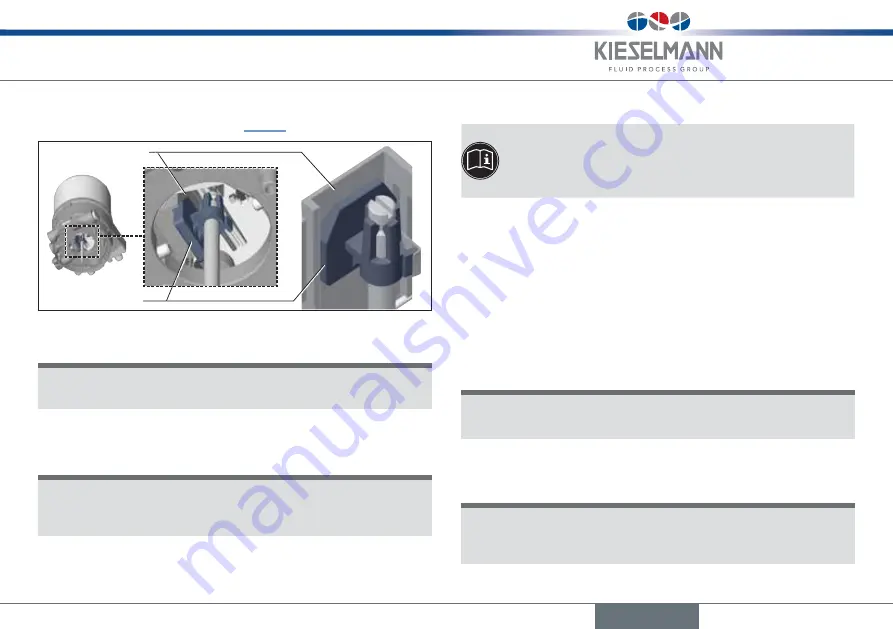

Type 8615500120-000 / 8615500130-000

2. Align the puck of the actuator with the guide rail of

Type 8615500120-000 (see "Fig. 7")

Guide rail

Puck

Fig. 7:

Aligning the puck

note!

damage to the pcB or malfunction!

▶

Ensure that the puck lies flat on the guide rail.

→

Push Type 8615500120-000 without turning it onto the actuator

until no gap is visible on the form seal.

note!

to comply with the degree of protection ip65 / ip67, do not

fasten the fastening screws too tightly.

▶

Maximum tightening torque: 0.5 Nm.

→

Attach Type 8615500120-000 to the actuator using the two side

fastening screws. In doing so, tighten the screws only hand-tight

(max. tightening torque: 0.5 Nm).

10.4 installation on rotary piston actuators

The installation of the switch spindle is described in the

operating instructions for Type 8615500130-000.

Additional information can be found on the Kieselmann

homepage.

10.5 installation on rotary actuators from

third party manufacturers

→

Align actuator and Type 8615500120-000 / 8615500130-000 to

each other (see installation instructions for the adaptation set).

→

Connect magnetic encoder to actuator shaft and attach using

setscrew (maximum tightening torque: 0.5 Nm).

→

Place angle of rotation sensor on magnetic encoder (attachment is

with the adaptation set; see associated installation instructions).

note!

damage to the sensor cable!

▶

Ensure that the sensor cable is not damaged during assembly.

→

Press down Type 8615500120-000 / 8615500130-000 as far

as the actuator.

note!

to comply with the degree of protection ip65 / ip67, do not

fasten the fastening screws too tightly.

▶

Maximum tightening torque: 0.5 Nm.

English

Summary of Contents for 8615500120-000

Page 93: ......

Page 94: ...www kieselmann de...