46

PFX2512_CE

Preparation of the DUT (battery) Connection

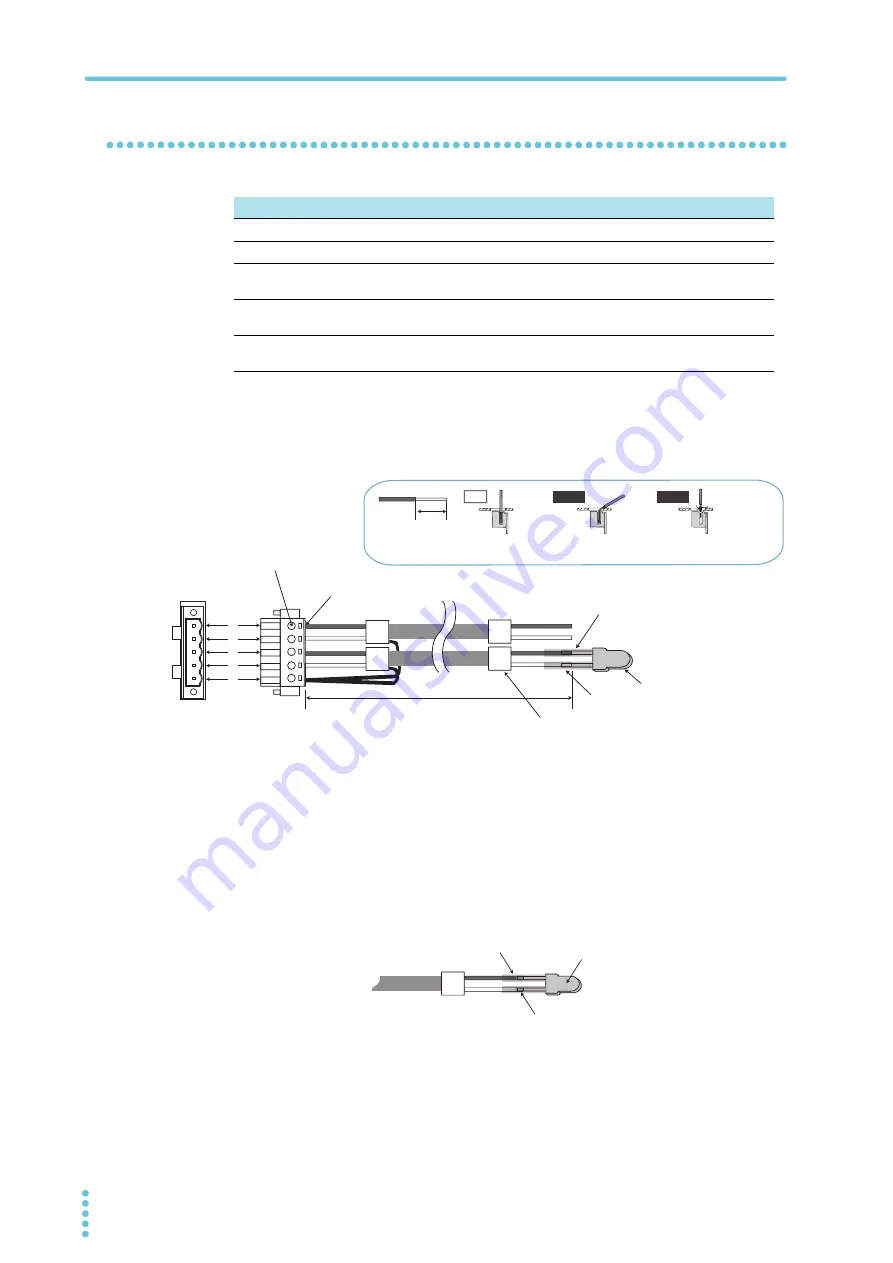

Making the sensing cable

1

Assemble the sensing cable using the wire of size for AWG 24 to 20 (0.20 mm

2

to 0.52 mm

2

).

2

Solder the thermistor lead to the tip of the temperature sensing cable.

As a guideline, the time for soldering the thermistor included in the package should

be less than 7 seconds at the position at least 5 mm away from the root of the lead

using a soldering iron (50 W) at 340

°

C.

There is no polarity on the thermistor.

Be sure to insulate the thermistor lead such as by using an heat-shrinkable tubing.

Pin No.

Symbol

Description

1

+

S

Positive voltage terminal. Connect to the positive terminal of the DUT (battery).

2

-

S

Negative voltage terminal. Connect to the negative terminal of the DUT (battery).

3

+

T

Temperature measurement terminal. Connect to the thermistor that comes with the

package.

4

-

T

Temperature measurement terminal. Connect to the thermistor that comes with the

package.

5

FG

Shield grounding terminal. It is connected to the chassis of the PFX2512. Do not

connect the shielding potential to any part of the DUT (battery).

1

2

3

4

5

7 mm

Fix the wire in place

using this screw.

Connector plug

included in

the package.

SENSING connector

on the rear panel

Insert the wire with 7 mm of

the covering removed here.

Length up to 5 m

Solder

Thermistor

2-conductor shielded wire

Heat-shrinkable tubing

or insulation tape

*Do not connect the shielding

potential to any place.

Voltage sensing cable

Temperature sensing cable

Yes

No

No

The wire is directly in

contact with the chassis.

The wire scrap is in

contact with the chassis.

Temperature

sensing cable

Solder

Thermistor

Heat-shrinkable tubing

or insulation tape

Summary of Contents for PFX2515

Page 10: ...10 PFX2512_CE This page is intentionally blank ...

Page 58: ...58 PFX2512_CE This page is intentionally blank ...

Page 59: ...Specification This chapter contains the PFX2512 specifications and outline drawings ...

Page 86: ...86 PFX2512_CE This page is intentionally blank ...

Page 100: ...100 PFX2512_CE This page is intentionally blank ...

Page 103: ......