6-4

TOS9213S/ TOS9213AS

6.2

SIGNAL I/O Connector

•

To pre

v

ent electric shock, t

u

rn off the de

v

ice

b

efore connecting/discon-

necting a ca

b

le.

•

Keep the signal line at least 500 mm from the high-

v

oltage test lead

w

ire

and the DUT. Do not short-circ

u

it the test

v

oltage to the signal line. Other-

w

ise, all internal circ

u

its may

b

e destroyed.

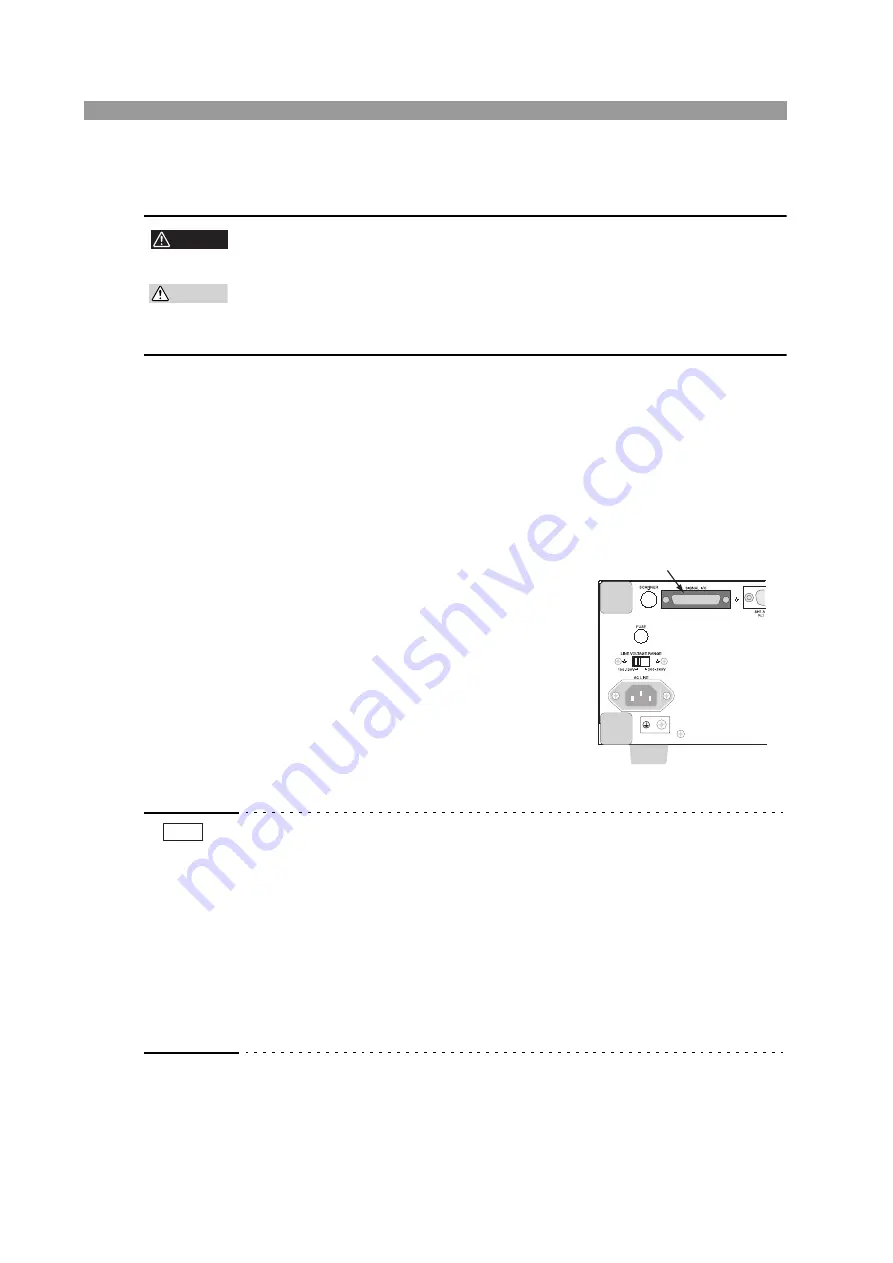

The SIGNAL I/O connector is the 25-pin D-SUB connector on the rear panel.

By inputting a signal to the SIGNAL I/O connector, a test can be started/stopped

and the panel memory and program memory can be recalled. In addition, the status

of the tester can be checked using the output signal from the SIGNAL I/O connec-

tor.

Connector on the rear panel

XM3B-2522 D-sub 25-pin female connector

(socket); manufactured by OMRON Corporation,

Screw M2.6 x 0.45

Complies connector (plug)

D-sub 25-pin male (with fix screw M2.6)

• For 25-pin D-SUB connectors and cables, use a shielded type with a length of 3 m

or less to prevent malfunction due to noise.

• The internal control circuit of the tester is designed to prevent malfunction caused

by noise generated by the tester or peripheral devices. However, connected

devices may malfunction if unshielded cables are connected to SIGNAL I/O ter-

minals, because such cables would virtually make a sort of “antenna” to pick up

external noise. To avoid this problem, use metal connectors, shielded cables, and

external circuits housed in a shielded case. Connect them to the tester’s housing

(do not connect the COM line to a shield or an earth ground). These measures

insulate SIGNAL I/O-related circuits from the external environment, thus reduc-

ing malfunction due to noise.

WARNING

CAUTION

SIGNAL I/O connector

OMRON Corporation:

XM2B-2502

Fig.6-2

SIG

N

AL I/O

NOTE