※

LED light flash in simulate-learning.( means under simulate- learning condition), push P key to record value

after simulate -learning. ).

※

When the screwdriver is left unused: Press “Up” then press “P”, set up the waiting time. Press again “P” to

set up the total finishing time 00~99. If set 1 minute, it will count the time after starting the screwdriver. If the

setting screw number are not finished within 1 minute, the buzzer sound will come out.

※

Press “P” to reset the system back to the default setting when the user needs it.

Work under default setting:

Start

To adjust the torque on these screwdrivers. Proceed as follows :

1. Determine the torque output of the tool by checking a

tightened Fastener with a torque wrench.

2. Increase or decrease the torque by rotating the Spring

Adjusting Ring. Rotating the Ring clockwise to a

higher number on the torque Scale increase torque

output while rotating the Ring counterclockwise to a

lower number decreases the torque output.

3. Check the adjustment with a torque wrench. A number

of factors will affect torque output from one job to

another. Final torque adjustment should be made at

the job through a of series of gradual increase. Always

start below the desired torque and work upward.

4. Adjust the bit torque by changing the driving in length

of the adjust ring at the end.

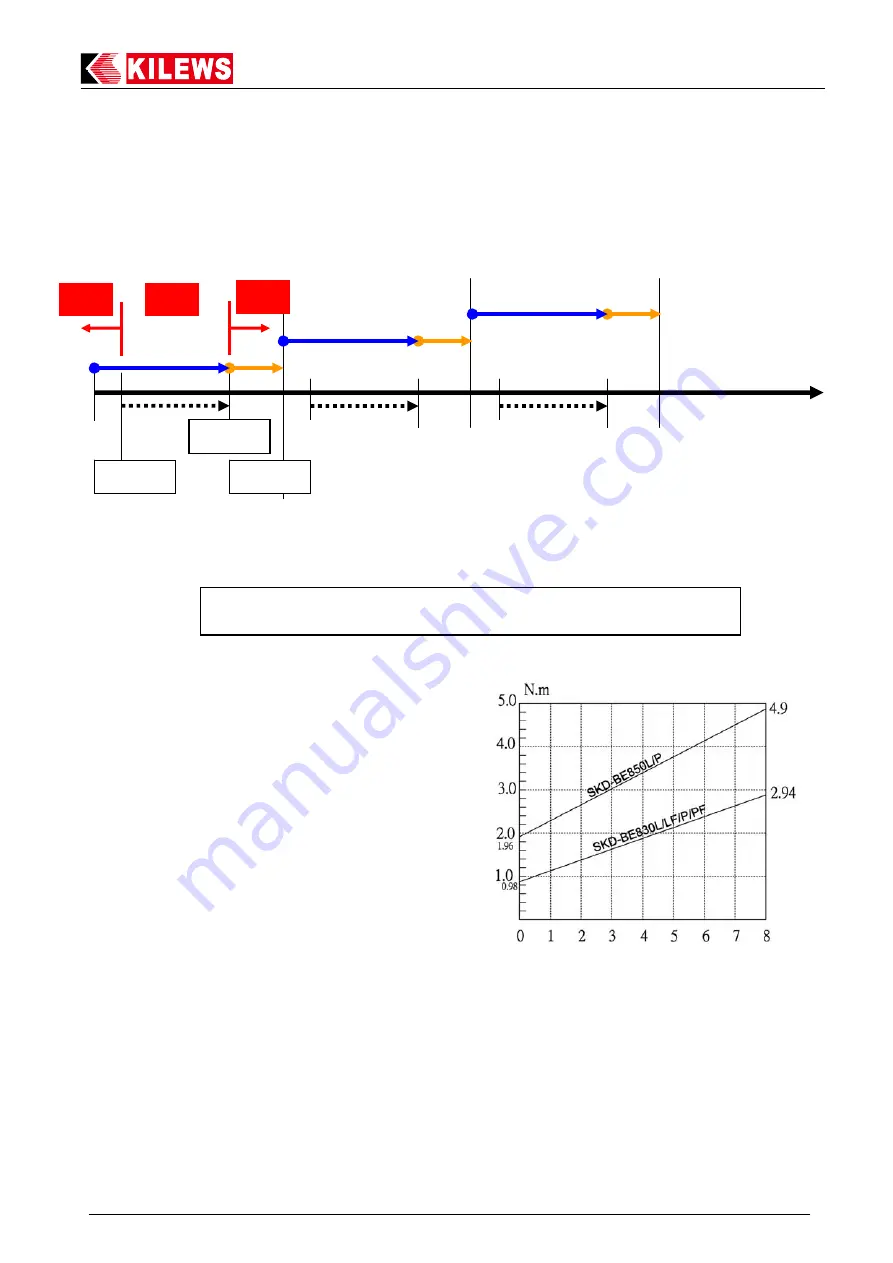

5. The relationship between torque scale and bit torque

is as shown Ring, in the torque diagram. The figures

of torque scale do not indicate bit torque values.

However, the clamping torque of screw itself is different form type, size, material of the screw and the

material of its mating part. Use it as standard to obtain an appropriate clamping torque.

6. The (Return torque method) in which once-clamped screw is returned with torque wrench or the like is

available as one of torque control methods however, note that the measured values by the return torque

method generally appear in 10%~30% lower than the actually clamping torque.

7. The torque checker measures the torque of screwdriver. The clamping torque of screw itself is different

from the clamped conditions. Understand the correlation between clamping torque values and the torque

checker values perform the torque control properly.

Lt=0.02

Ht=2.0

LL=1.0

* If stop is among dots, it is normal fastening. “OK”will be shown.

* If stop is before Ht or over Lt, it is “N.G.”.

* User can freely adjust Ht. However, if Ht and Lt is closer, it will request more precise.

Torque Adjustment Operation

N.G

*

If stop is among dots, it is normal fastening. “OK”will be shown.

*

If stop is before Ht or over Lt, it is “N.G.”.

*

User can freely adjust Ht. However, if Ht and Lt is closer, it will request more precise.

OK

N.G