Assembly Instructions

Perks

Page 1 of 1

Proper product installation, in accordance with these instructions, is the responsibility of the installing agent.

If you have any questions concerning these instructions, please call Kimball Office Customer Service.

Part No. 2066772

Revision A-08

Undersurface

Power/Data Center

Tools Required

■

Screwdriver

Package Contents

■

1 Electrical Module

■

2 Screws

■

1 Mounting Frame

Installation

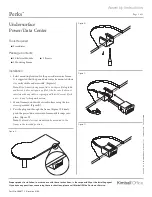

1. Select mounting location for the power/data center frame.

It is suggested that the power/data center be mounted where

it is easily visible and accessible. (Figure A).

Note:

If the frame is being mounted to an Aspire folding table,

make sure it does not span any folds. Also, be sure it does not

interfere with any cables or springs and that it does not block

access to any locking mechanisms.

2. Mount frame to underside of worksurface using the two

screws provided. (Figure B).

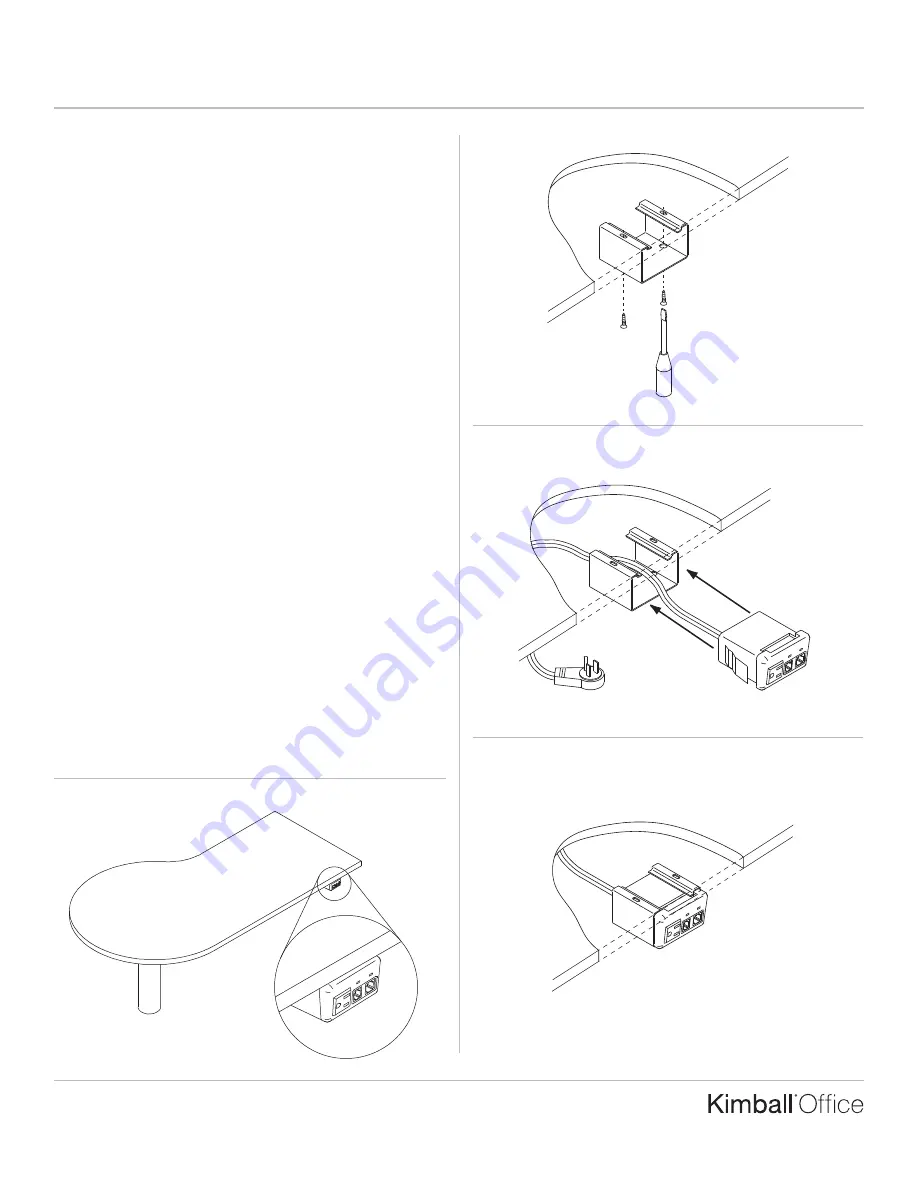

3. Pass the plug end through the frame. (Figure C). Firmly

push the power/data center into frame until it snaps into

place. (Figure D).

Note:

If desired, electrical module can be mounted in the

frame in the inverted position.

Figure B

Figure C

TM

Figure A

Figure D

P

ri

n

te

d

in

U

.S

.A

.

©

2

0

0

8

K

im

b

a

ll

In

te

rn

a

ti

o

n

a

l,

In

c

.

T

8

0

0

.4

8

2

.1

8

1

8

F

8

1

2

.4

8

2

.8

3

0

0