PNEUMATIC LEVEL CONTROLLER

PNEUMATIC LEVEL CONTROLLER

MODEL: GEN 3

Installation, Operation & Maintenance Guide

MODEL: GEN 3

Installation, Operation & Maintenance Guide

www.kimray.com

4

CAUTION:

When ordered, the controller configuration & construction

materials were selected to meet specific pressure,

temperature, & fluid conditions. Do not subject the

controller to any other conditions without first contacting

the Kimray Inc, sales office or a sales / applications

representative.

A4 Tools Needed for Installation,

Conversions & Repair

This Kimray controller DOES NOT require special tools

for disassembly, inspection & assembly.

These are the standard tools required:

1. Pipe Wrench or other Wrench to fit 2-1/2" Flats.

2. 7/8" wrench for lower 1/2" NPTs

3. 9/16" wrench for Gauges -or- Adjustable Wrench

4. 9/16" socket for the mount screws

5. 3/8" Socket for Pilot Cartridge Caps

6. 1/4" hex key for 1/4" NPT plugs

7. 1/8" Hex Key (included with unit) see below.

8. Thread tape

9. Any equipment needed for tubing connections

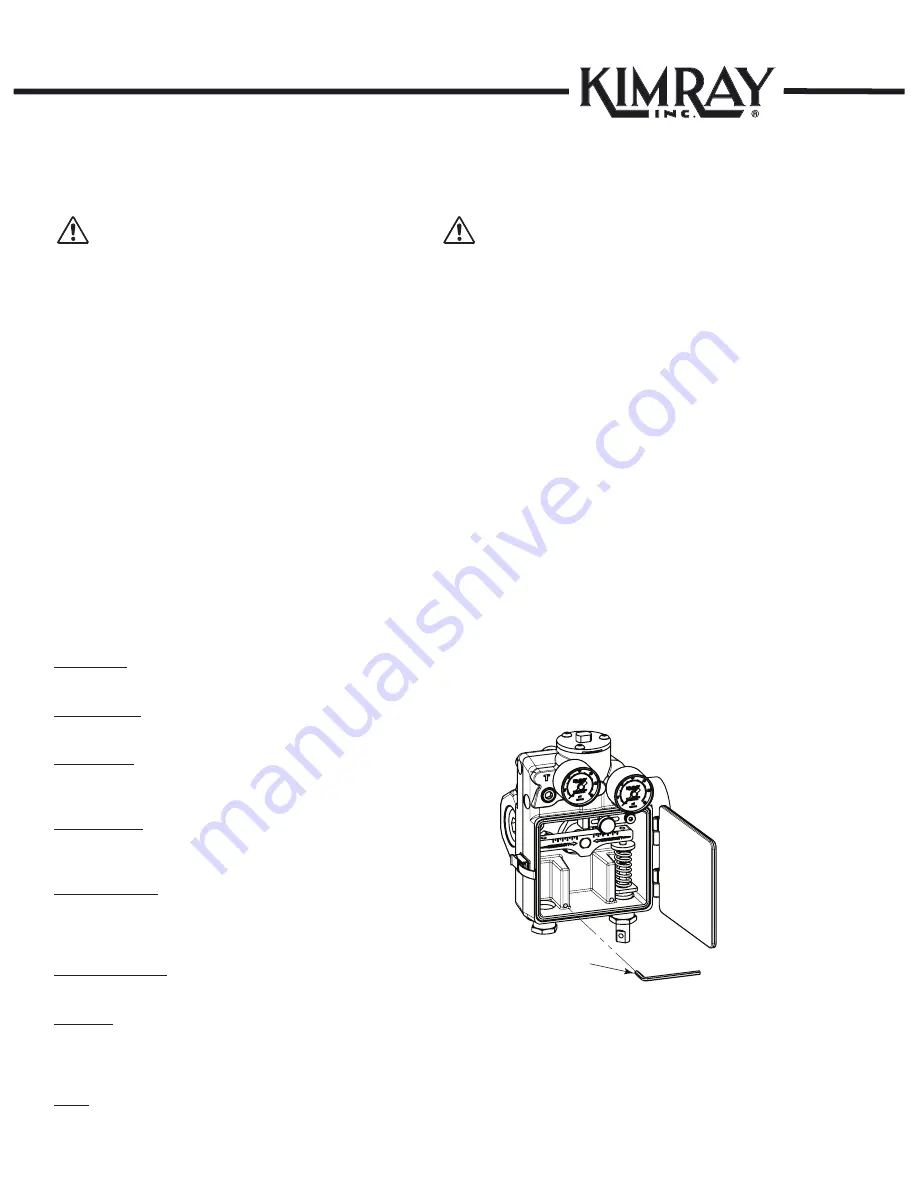

The Gen 3 includes a 1/8" hex key which will fit the pilot

& lever fasteners.

For convenience, the hex key can be stored in the

location shown below.

1/8" Hex key

CAUTION:

The instructions provided herein should be completely

reviewed & understood before installing, operating or

repairing this equipment. All

CAUTION

&

WARNING

notes must be strictly observed to prevent injury to

personnel or damage to equipment.

A1 Scope

This document contains information for the Gen 3 Liquid

Level Controller & includes detailed installation, operation

& repair/maintenance information for the product.

A2 Description

The Gen 3 Liquid Level Controller is designed for use in

single-phase & interface liquid control applications. The

pilot is capable of both Snap mode (on/off) & Throttle

mode (modulating). Pneumatic output can be set to

operate as Direct Acting or Indirect Acting. The mounting

body can be flipped to either Left Hand or Right Hand

Mount. The displacer may be assembled in vertical or

horizontal orientation. Changing between these options

does not require additional components nor swapping

out pilots.

A3 Definitions

Snap Mode: On/Off, discrete output. Liquid level ranges

from high point to low point, large span.

Throttle Mode: Modulating, proportional output. Holds

consistent level, with very small span.

Direct Acting: For Fail Closed (FC) aka Pressure-to-Open

(PO) Valve. Pilot provides maximum output when liquid

level reaches set point at top of span.

Indirect Acting: For Fail Open (FO) aka Pressure-to-

Close (PC) Valve. Pilot provides maximum output when

liquid level reaches bottom of span.

Left Hand Mount: With front of controller facing operator,

unit is mounted on left side of vessel. For Back Mount

applications, use this mount option due to the location of

the cover latch.

Right Hand Mount: With front of controller facing

operator, unit is mounted on right side of vessel.

Set Point: The liquid level at which the controller opens

the valve. In Snap Mode, this is at the top of the span. In

Throttle Mode, the liquid level should stay consistent at

the set point.

Span: Distance between the highest & lowest liquid level

during operation. This can be set with the Sensitivity

Fulcrum. See “Span Adjustment” below.

Introduction