Float Operated Level Controllers

Models Pneumatic GEN II

Installation and Maintenance

1

IM0015

Kimray Inc.- 52 NW 42nd Street Oklahoma City, Ok 73118 USA - Ph: (405) 525-6601, Fax: (405) 525-7520 - Kimray.com

INTRODUCTION

CAUTION

Prior to installing, the instructions provided

herein should be completely reviewed and

understood before operating or repairing this

equipment . All CAUTION and WARNING

notes must be strictly observed to prevent

personal injury or equipment damage.

Scope

This installation manual includes instructions

and maintenance information for both

Kimray pnuematic side mount and back

mount level controllers.

Do not install, operate, or maintain a

pneumatic GEN II without being fully trained

and qualified with Kimray installation and

maintenance manual. To avoid personal

injury or property damage, it is important to

carefully read, understand, and follow all the

contents of this manual, including all safety

cautions and warnings. If you have any

questions about these instructions, contact

your Kimray applications support group

before proceeding.

CONTENTS

PAGE

Introduction

1

Scope

1

Description

1

Specification

1

Control Installation

2

Table 1 -

General Specifications

Description:

Pneumatically Operated

Level Controller.

Operating

Pressure:

(0-4000) psig (276 Bar)

Connection Size:

2in. - 6in.

Body Material:

Steel

Connection Type:

NPT, Flg, Grv, HU

Grooved

Actuation:

Snap, Throttle

Adjustable

Control Range:

2 - 10 in.

Temperature:

-50° to 300° F

-45° to 149° C

Specification

Description

The GEN II side mount and back mount

level controllers are designed for use in

liquid

level and liquid/liquid interface control

applications

. Both provide either a

throttle

modulating or snap on/off pneumatic

output and can be set to operate in a

direct increasing liquid level output signal

or

indirect mode increasing liquid level

decreasing output signal

.

The GEN II level controllers are equipped

with a displacer or hanger for horizontal or

vertical installation.

Before beginning installation of the GEN II

•Read and follow instructions.

•Make sure all pressure has been removed

from the vessel before opening any connec

tions.

WARNING

If a level controller is used in a hazardous

or flammable fluid service, personal injury

and property damage could occur due to

fire or explosion of vented fluid that may

have accumulated. To prevent such injury

or damage, install piping or tubing to vent

the fluid to a safe, well-ventilated area

or containment vessel. When venting a

hazardous fluid, the piping or tubing should

be located far enough away from any

buildings or windows so as not to create

further hazard. The vent opening should

be protected against anything which could

obstruct it, or it should by connected to

exhaust tubing or tubing connected to a

vapor recovery system.

Vent

Periodically check the vent opening or

the end of the remote vent pipe, if one is

required. Be certain they are clear. If a vent

should become blocked the pilot could lose

control.

CAUTION

When ordered, the GEN II level controller

configuration and construction materials

were selected to meet specific pressure,

temperature, pressure drop and fluid

conditions. Since some body/trim material

combinations are limited in their pressure

drop and temperature ranges, do not subject

the GEN II level controller to any other

conditions without first contacting the Kimray

Inc, sales office or a sales / applications

representative.

WARNING

Do not exceed the maximum pressure

specified on the controller nameplate. Under

no circumstances should the controller

supply pressure ever exceed the maximum

psig.

The side mounted is reversible for rigtht hand

or left hand installation. The

back mount is center back mounted. Both

models are standard with a 1/4” NPT tapped

vent. No gas is released into the case.

Both models include a 40 micron filter

located just downstream of the instrument

gas inlet port.

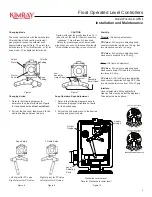

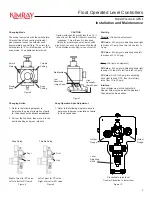

Back Mount

Side Mount

Issued 6/19