Issue

N

C.S.

04.03.20

Trading Estate Farnham Surrey England

Doc. No. TD 120

Page 14 of 25

6. MAINTENANCE AND TROUBLESHOOTING

The EL positioner is designed to be maintenance free during a long life, if it is supplied with clean, dry oil free air, and

electrical signals free of noise and high voltage spikes.

When the lid is removed, take care not to wipe all grease from shaft lip seal.

Table 2 is a troubleshooting guide, which aims to assist only with simple easily remedied problems. If problems persist,

contact Kinetrol or a Kinetrol distributor for further assistance.

TABLE 2. Troubleshooting Guide.

Refer to TD 181 for a visual guide to troubleshooting and part replacement.

Failure to move when signal and air are connected:

- Check air pressure – must be above 50psi./3.5 Bar.

- Check signal is connected with correct polarity.

- Check signal is really above 4 mA

- Discrete units – is shaft connected in correct orientation? The feedback pot strap may need replacing if

orientation is incorrect.

- Has main feedback pot been rotated, or does it need rotating because the unit has been subjected to change in

direction of movement on loss of signal? See section 5.11 – Resetting Feedback Pot.

- Is air supply clean, dry, and oil free?

Unit moves slower than expected up-scale or downscale:

- Check air pressure – above 50psi / 3.5 Bar?

- Check flow adjuster screws – has one been screwed in?

- Is air supply clean, dry and oil free? If not there is a possibility that the positioner servo has been damaged.

Movements are too jerky:

- Ensure coupling screw is not too tight (see section 3.1.5)

- Adjust proportional gain to increase smoothness – then reset damping and setpoints as instructed in Section 4.

Lack of sensitivity to changes in signal:

- Adjust proportional gain to increase sensitivity – then reset damping, and setpoints as instructed in Section 4.

Set point is overshot when positioner moves rapidly:

- Adjust damping to eliminate overshoot.

Title : Installation, Operation & Maintenance Instructions – IS Digital EL Positioner

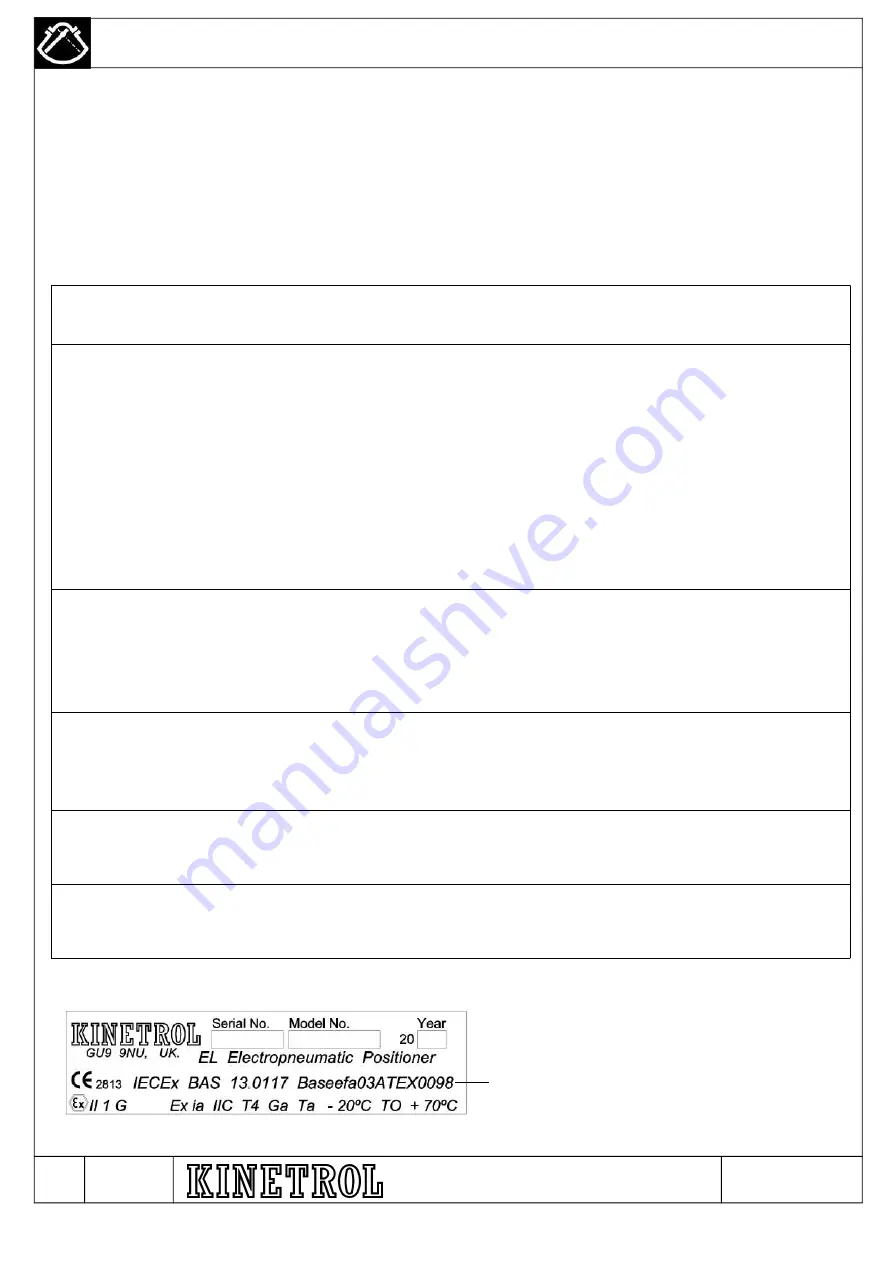

7. IDENTITY LABEL

N – AR7059 / M – AR6971 / L - AR6419 / K - AR6347 / J-AR6096 / H – AR 6082 / G – AR 5487 / F – AR 5608 / E - AR 5293

7. IDENTITY LABEL

NOTE: ‘X’ NOT INCLUDED WHEN CASE IS ZINC ALLOY.