Issue

N

C.S.

04.03.20

Trading Estate Farnham Surrey England

Doc. No. TD 120

Page 4 of 25

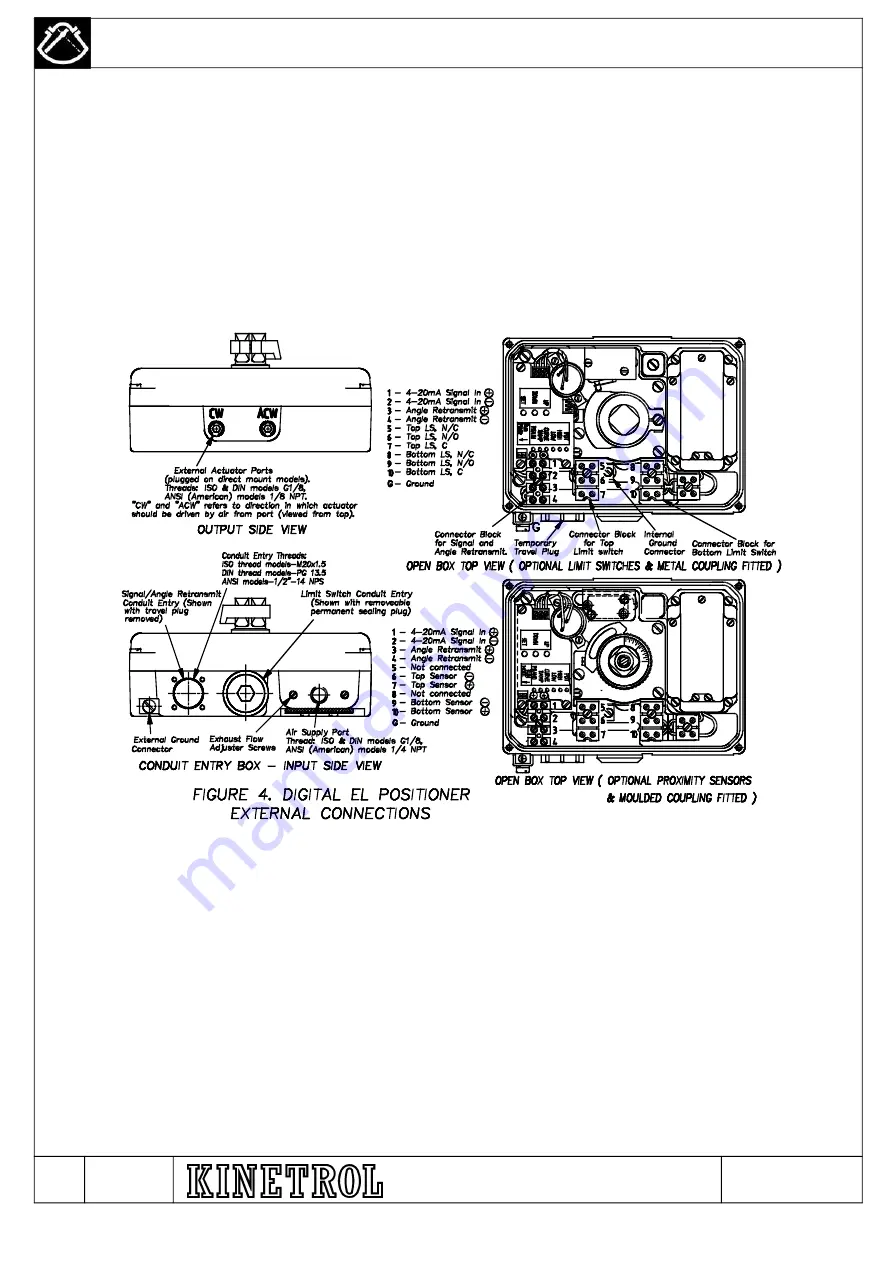

3.3.1 Air supply.

Connect air supply (pressure between 3.5 and 7 bar, 50 and 100psi.) to the supply port. It is essential that the air is clean, dry

and oil-free. Quality class 6.4.4 (according to ISO standard 8573.2001) is easily adequate – this implies 5 micron max.

particle size, 3ºC dew point max., and 5 mg/cubic metre max. oil content. If ambient temperature is lower then 8ºC, ensure

that the dew point is 5ºC lower than the ambient temperature.

3.3.2 DIN Plug Option.

The DIN plug option is not available on intrinsically safe positioners.

3.2 Mounting of Discrete Positioner

Design and manufacture of the mount kit between positioner and actuator is outside the scope of this document. It is essential

that the shaft of the actuator is well aligned with the positioner shaft, and that the two are coupled together with a minimum of

backlash – any backlash acts to deteriorate the performance of the positioner/actuator combination.

It is also essential that the 90 degree travel of the actuator moves the positioner shaft through the correct 90 degree

range of travel. The easiest way to ensure that this happens is to mount the discrete unit with the lid and indicator in place –

set both the actuator and positioner to mid travel, and mate the two in this orientation. Don't take any chances with this, since

misorientation of the positioner shaft and consequent movement beyond its designed range of travel will probably result in

damage to the positioner pot drive mechanism. With moulded coupling versions, the Namur drive or Kinetrol square option is

an insert in the coupling which can be removed by releasing the central screw.

3.3 Air and Electrical Connections.

Title : Installation, Operation & Maintenance Instructions – IS Digital EL Positioner

N – AR7059 / M – AR6971 / L - AR6419 / K - AR6347 / J-AR6096 / H – AR 6082 / G – AR 5487 / F – AR 5608 / E - AR 5293