Issue

N

C.S.

04.03.20

Trading Estate Farnham Surrey England

Doc. No. TD 120

Page 6 of 25

Title : Installation, Operation & Maintenance Instructions – IS Digital EL Positioner

5. SET UP.

5.0 Introduction

When the positioner/actuator combination is installed in its application, set up the control adjustments if necessary. For most

applications, it is likely that the factory settings will be satisfactory – the low and high current points are set to give 0-90 degree

movement in response to a 4-20mA signal, the flow regulators are set for maximum travel speed, and the proportional gain and

damping settings adjusted for a good level of sensitivity and smoothness suitable for most applications. The jumper is set in the

“off” position to give a linear characteristic with travel extrapolated beyond the low and high current settings. If you need to

change the settings, read the following section carefully.

5.1 Setting Travel Speed.

Set the travel speed using the exhaust flow adjuster screws (see Figure 4.).

This only applies if you want to reduce the speed from its supplied maximum

factory setting.

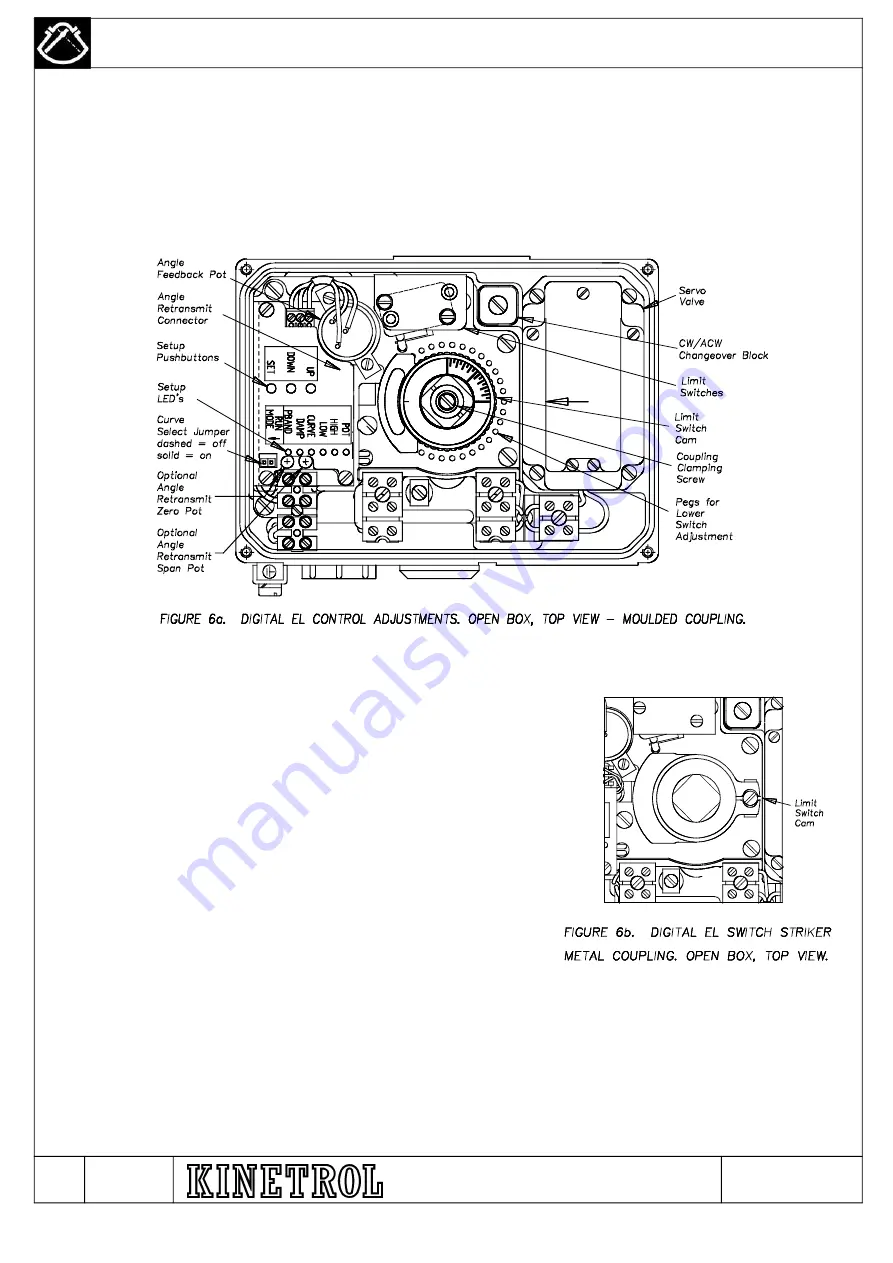

5.2 Setting Limit Switch Cams (Optional Equipment).

Limit switch cams are factory set (if fitted) to give end-of-travel switching with

one switch at each end. The two possible types of coupling require slightly

different approaches to setting.

5.2.1

Moulded coupling cams, shown in figure 6a, can be adjusted using light

pressure to rotate in 1 degree increments. Adjust the lower cam first using a

screwdriver to lever against special pegs moulded into the carrier plate or

use finger pressure. Secondly move the upper cam using finger pressure

only. Graduated marks on the top of the coupling are provided to gauge the

position of the actuator with the lid removed. This can be lined up with an

arrow marked on the servo valve lid.

5.2.2

Metal coupling cams are adjusted by releasing the screw shown in figure 6b, moving to desired position and re

tightening. Set the lever cam first. Ensure the clamp section of the cam does not strike a switch at any part in the actuator's

travel.

N – AR7059 / M – AR6971 / L - AR6419 / K - AR6347 / J-AR6096 / H – AR 6082 / G – AR 5487 / F – AR 5608 / E - AR 5293