CONTACT SAFETY TRIP MECHANISM

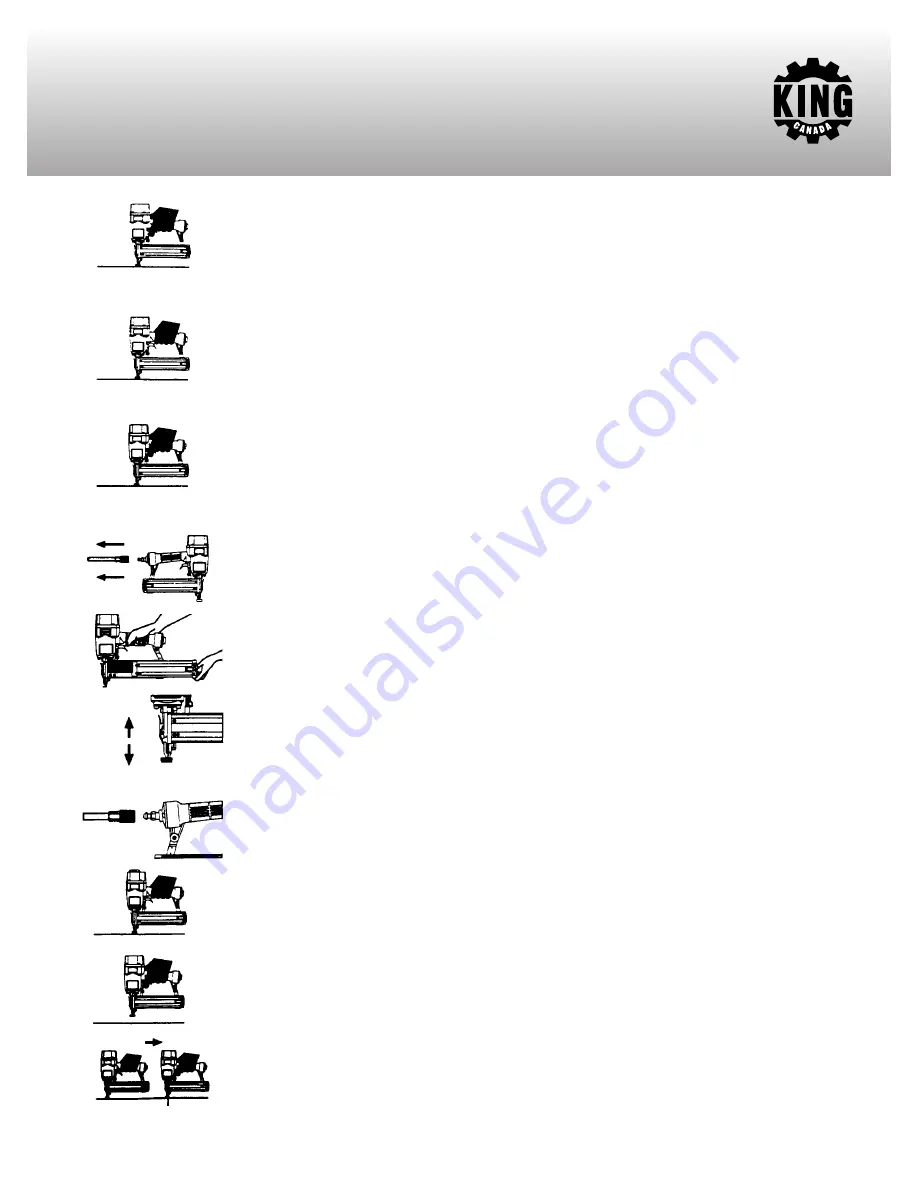

OPERATING A CONTACT SAFETY TRIP TOOL:

• The operator is required to have the finger off the trigger and the nose of the nailer/stapler to be placed

on the workpiece.

• The contact safety trip mechanism is then depressed against the workpiece and the trigger is pulled to

drive the nail or staple.

• The trigger is released after each nail or staple is driven.

• Move the nailer/stapler to the next location and repeat the above procedure.

VERIFICATION

• Disconnect the air supply from the air inlet.

• Empty all nails or staples from the magazine.

• Make sure the trigger and the contact safety trip mechanism moves up and down without sticking.

• Connect the air supply to the nailer/stapler air inlet.

• Depress the contact safety trip mechanism against the workpiece without pulling the trigger. The

nailer/stapler must not cycle.

Never use the tool if a cycle occurs.

• Hold the nailer/stapler clear of the workpiece. The contact safety trip mechanism should return to its

original down position. Pull the trigger. The tool must not cycle.

Never use the nailer/stapler if a

cycle occurs.

• Depress the contact safety trip mechanism against the workpiece and pull the trigger, the nailer/stapler

must cycle.