ASSEMBLY & OPERATION

Warning!

For your own safety, do not connect the log splitter to the power

source until the machine is completely assembled and you have read and

understood the entire instruction manual.

Warning!

Never use the log splitter if it is not in perfect order or if it needs

servicing. Before starting work, check correct functioning of all the safety

devices (power button).

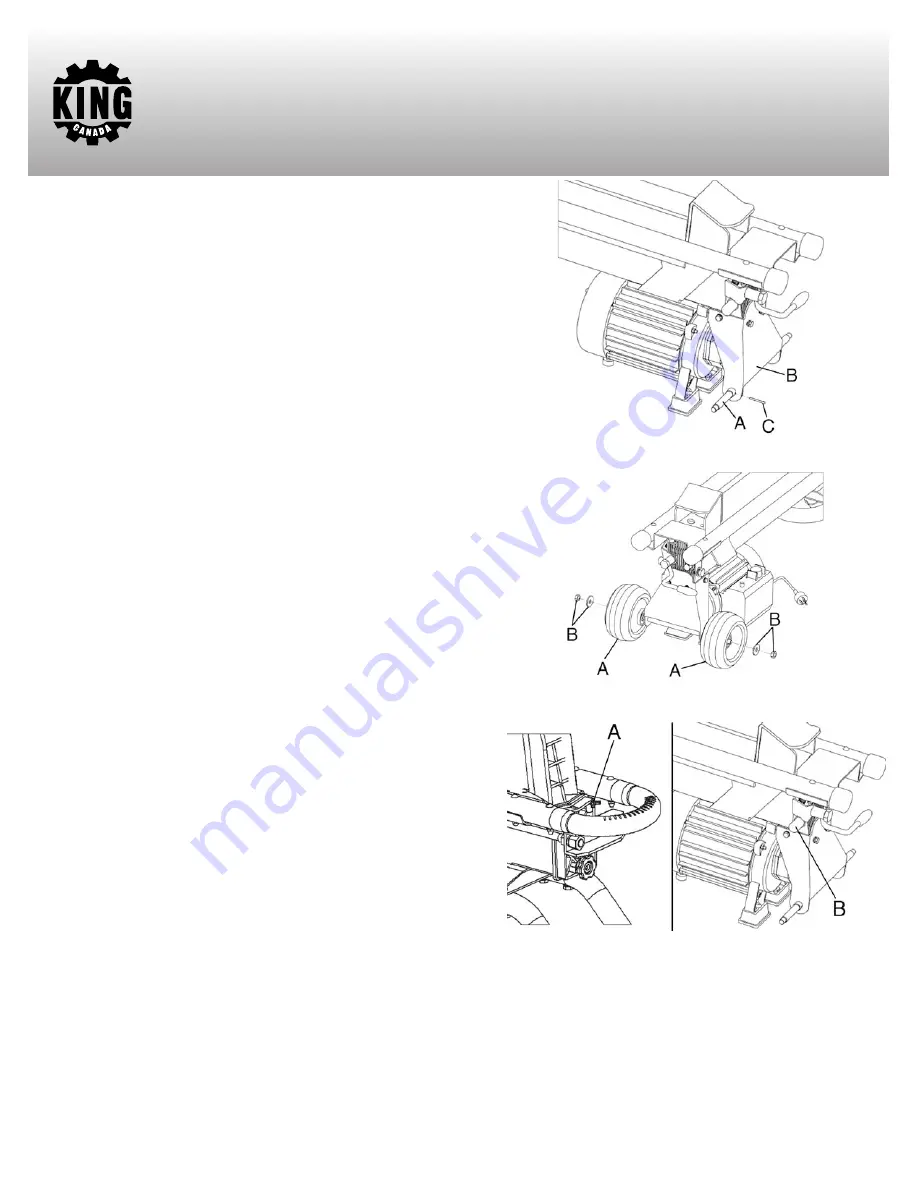

Assembling Wheels

Before operating the log splitter, it is necessary to fit both wheels on the

supporting shaft.

1) Slide the wheel shaft (A) Fig.4 into the wheel bracket (B). Secure the

wheel shaft with the provided cotter pins (C).

2) Slide both wheels (A) Fig.5 onto the wheel shaft and secure them using

the washers and lock nuts (B).

Operation

VERY IMPORTANT

WARNING! BEFORE OPERATING THE LOG SPLITTER, THE BLEED

SCREW (A) FIG.6 MUST BE LOOSENED BY SOME ROTATIONS UNTIL

AIR CAN GO IN AND OUT OF THE OIL TANK SMOOTHLY.

AIR FLOW THROUGH THE BLEED SCREW HOLE SHOULD BE

DETECTABLE WHILE THE LOG SPLITTER IS UNDER OPERATION.

BEFORE MOVING THE LOG SPLITTER, MAKE SURE THE BLEED

SCREW IS TIGHTENED TO AVOID OIL LEAKING FROM THIS POINT.

FAILURE TO LOOSEN THE BLEED SCREW WILL KEEP THE SEALED

AIR IN HYDRAULIC SYSTEM BEING COMPRESSED AFTER BEING

DECOMPRESSED. SUCH CONTINUOUS AIR COMPRESSION AND

DECOMPRESSION WILL BLOW OUT THE SEALS OF THE HYDRAULIC

SYSTEM AND CAUSE PERMANENT DAMAGE TO THE LOG

SPLITTER. DO NOT ADJUST THE MAX PRESSURE LIMITING SCREW

(B) Fig.6.

Max pressure was set during production and the max pressure limiting

screw is tightened to ensure the log splitter works under pressure of no

more than 6 tons. The setting was done by qualified mechanics with

professional instruments. Unauthorized resetting will cause the hydraulic

pump to fail to output enough splitting pressure or RESULT IN SERIOUS

INJURY AS WELL AS DAMAGE TO THE MACHINE. The max pressure

limiting screw (B) Fig.6 is protected by a plastic cap. If the plastic cap gets

loosened, adjust it.

FIGURE 4

FIGURE 5

FIGURE 6