STARTING ENGINE, LOADING

& SPLITTING LOGS

STARTING YOUR ENGINE

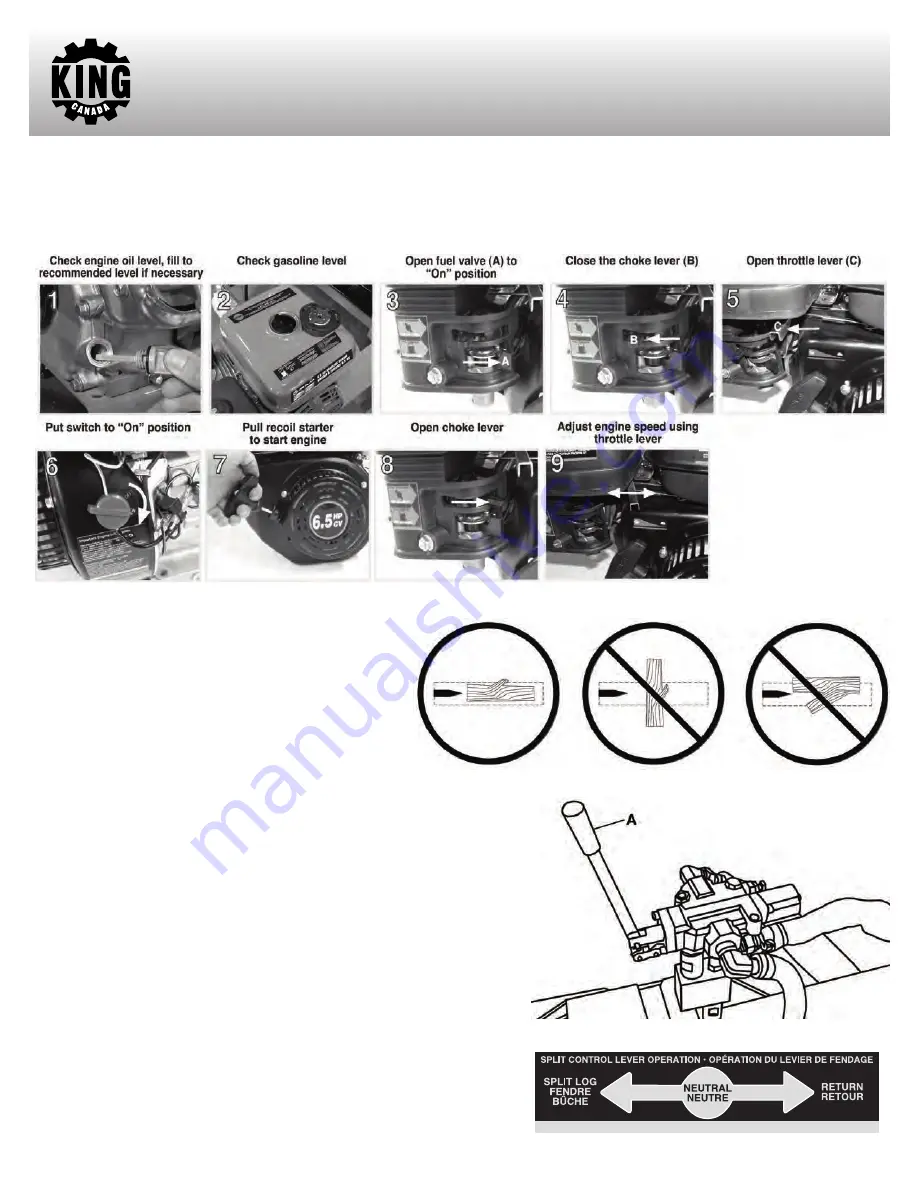

To safely start your engine, follow these steps (Fig.19).

Note: No choke is required on warm engines. Pull the recoil starter handle until resistance is felt, then pull it out with a rapid full arm stroke. Let

the starter rope rewind slowly, repeat if necessary. Allow engine to run at no load for 5 minutes upon each initial start-up to allow engine to stabi-

lize.

STOPPING YOUR ENGINE

1) Move the throttle lever (step 9, Fig.19) towards the right.

2) Turn the engine switch (step 6, Fig.19) to the “OFF” position

(upwards).

3) Close the fuel shut-off valve (step 3, Fig.19) by moving it to-

wards the left.

LOADING LOGS (Fig.20)

Load log onto beam with a cut end against the endplate – posi-

tioned for a lengthwise cut.

Notes:

a) The log splitter is designed only for cutting lengthwise with the grain, NOT for

cutting across the grain.

b) This log splitter is designed for cutting logs only up to a maximum of 16” in di-

ameter and 21” long. Larger diameter logs could get stuck on the wedge and

longer logs will not fit on the beam.

wARNING:

ALWAYS keep hands and feet away from the endplate, wedge, and

partially split logs while loading, operating and unloading the log splitter.

Important safety instruction: Vertical position loading: Place the log on the endplate

and turn it until it leans against the beam and is stable. If the log is too big or oddly

shaped, stabilize the log with wooden shims between the log and endplate or

ground. DO NOT use your leg or knee to stabilize the log. NEVER stabilize the log

by placing your hand on top of the log.

Splitting Operation

1) Move split control lever (A) Fig.21 toward endplate to extend wedge and split

log.

2) Release split control lever to stop wedge movement when log is split.

WARNING: Cracks in logs can close quickly and pinch fingers. Keep fingers away

from any cracks that open in partially split logs.

Figure 19

Figure 20

Figure 21

Figure 22