ADJUSTMENTS & OPERATIONS

USING THE TWIN LASER GUIDE SYSTEM

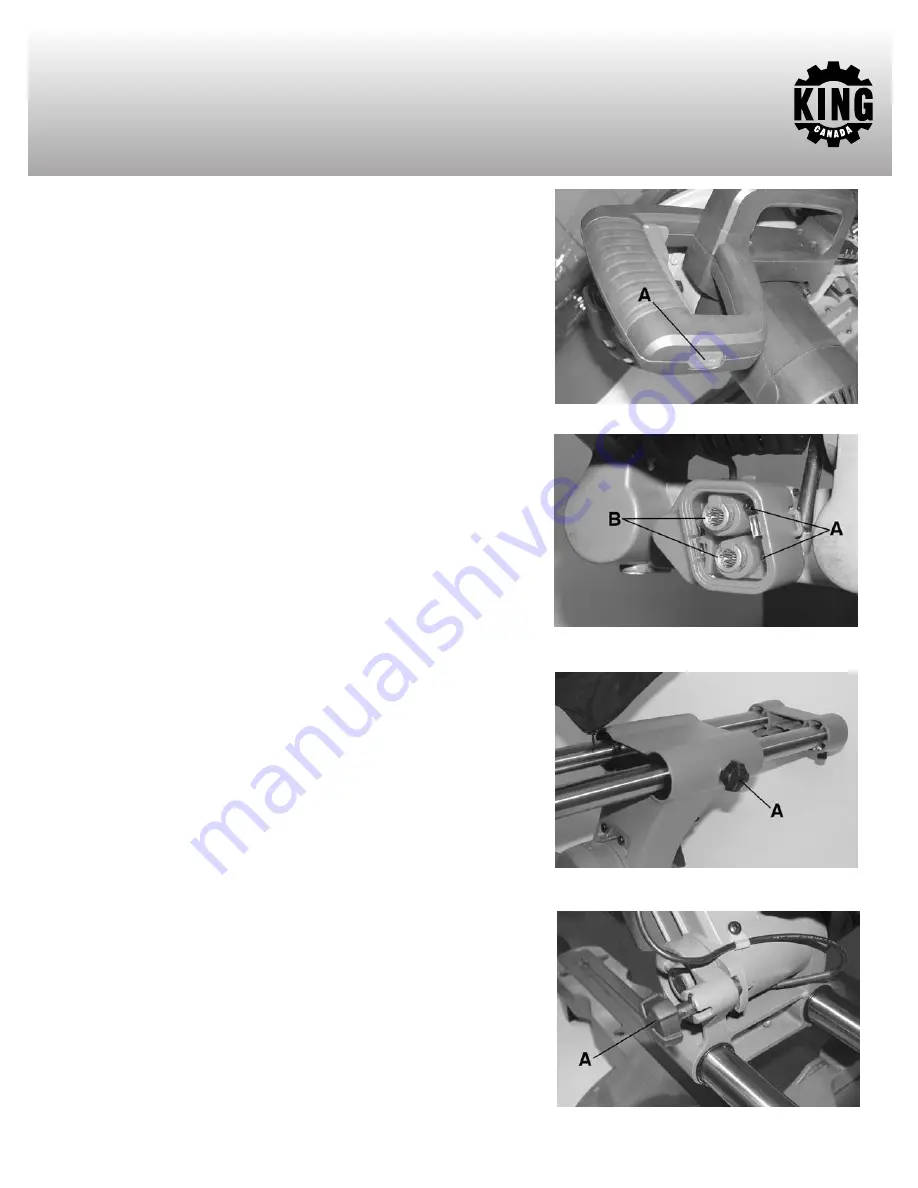

The twin laser guide system is controlled by the laser guide push button switch (A)

Fig.14 and will only turn on when the miter saw is plugged into a power source.

Warning! Do not stare directly into the laser beams.

1. Mark the line of the cut on the workpiece.

2. Adjust the miter and/or bevel angles as required.

3. Before clamping the workpiece in position using the vertical vise, align the line of

cut on the workpiece with the laser guide beam on either side of the blade kerf.

4. Start the motor.

5. When the blade reaches its maximum speed (approx. 2 sec.), lower the blade

through the workpiece.

ADJUSTING TWIN LASER GUIDE SYSTEM

If your laser guide does not seem to be aligned with both sides of the blade kerf, a

small adjustment can be made.

1. Remove the laser guide protective plastic cover.

2. Loosen pan head screws (A) Fig.15 next to each laser guide (B).

3. Place a scap piece of wood on the table and clamp it. Turn on miter saw and

make a partial cut to indicate both sides of the blade kerf.

4. Turn both laser tips (B) until the laser beams are perfectly aligned with both sides

of the blade kerf, once aligned, hold laser tip and retighten pan head screw (A)

to prevent the laser dial from moving. Repeat for the second laser tip.

5. Reinstall the laser guide protective plastic cover.

CUTTING OPERATIONS

CROSSCUTTING

When cutting a piece of wood it is not always necessary to use the slide

mechanism. In these cases make sure that the slide lock knob (A) Fig.16 is locked

to prevent the saw arm from sliding.

A crosscut is made by cutting across the grain of the workpiece. A 90

0

crosscut is

made with the miter and the bevel angles are set at 0

0

.

1. Pull and turn the saw head release knob (A) Fig.17 and lift the saw head to its

full height.

2. Loosen the miter lock handle.

3. Rotate the miter table using miter handle until the pointer aligns with the 0º.

4. Retighten the miter lock handle.

WARNING: Be sure to tighten the miter lock handle before making a cut. Failure to

do so could result in the table moving during the cut and cause serious personal

injury.

6. Place the workpiece flat on the table with one edge securely against the fence.

If the board is warped, place the convex side against the fence. If the concave

side is place against the fence, the board could break and jam the blade.

7. When cutting long pieces of timber, support the opposite end of the timber with

the extension wing or an additional roller stand or a work surface that is level with

the saw table.

8. Use a vise or clamp to secure the workpiece whenever possible.

9. Before turning on the saw, perform a dry run of the cutting operation to check

that there are no problems.

10. Hold the handle firmly and squeeze the trigger. Allow the blade to reach

maximum speed.

11. Slowly lower the blade into and through the workpiece.

12. Release the switch trigger and allow the saw blade to stop rotating before

raising the blade out of the workpiece. Wait until the blade stops before

removing the workpiece.

Figure 14

Figure 15

Figure 16

Figure 17