ASSEMBLY &

BREAK-IN PROCEDURES

ASSEMBLY AND LOCATION OF THE AIR COMPRESSOR

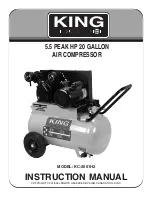

Your compressor requires some minor assembly. Install both 10” wheels (A)

Fig.3 using axle bolts, spring washers, washers and hex. nuts supplied.

Then install the rubber foot (B) using a large hex. bolt and hex. nut. Install

handle (C) to the tank and secure handle using 2 set screws (D).

Operate the air compressor in a dry, clean, cool, well ventilated area. The air

compressor pump and case are designed to allow for proper cooling. Clean

or blow off dust or dirt that collects on the air compressor. A clean air

compressor runs cooler and provides longer service. The ventilation

openings on your air compressor are necessary to maintain proper

operating temperature. Do not place rags or other containers on or near

these openings.

*IMPORTANT BREAK-IN PROCEDURES*

NOTE: SERIOUS DAMAGE MAY RESULT IF THE FOLLOWING

BREAK-IN INSTRUCTIONS ARE NOT CLOSELY FOLLOWED. THESE

PROCEDURES ARE REQUIRED BEFORE THE AIR COMPRESSOR CAN

BE PUT INTO SERVICE, AFTER REPLACING THE CHECK VALVE, AND

WHEN A PISTON OR A CYLINDER SLEEVE ARE REPLACED.

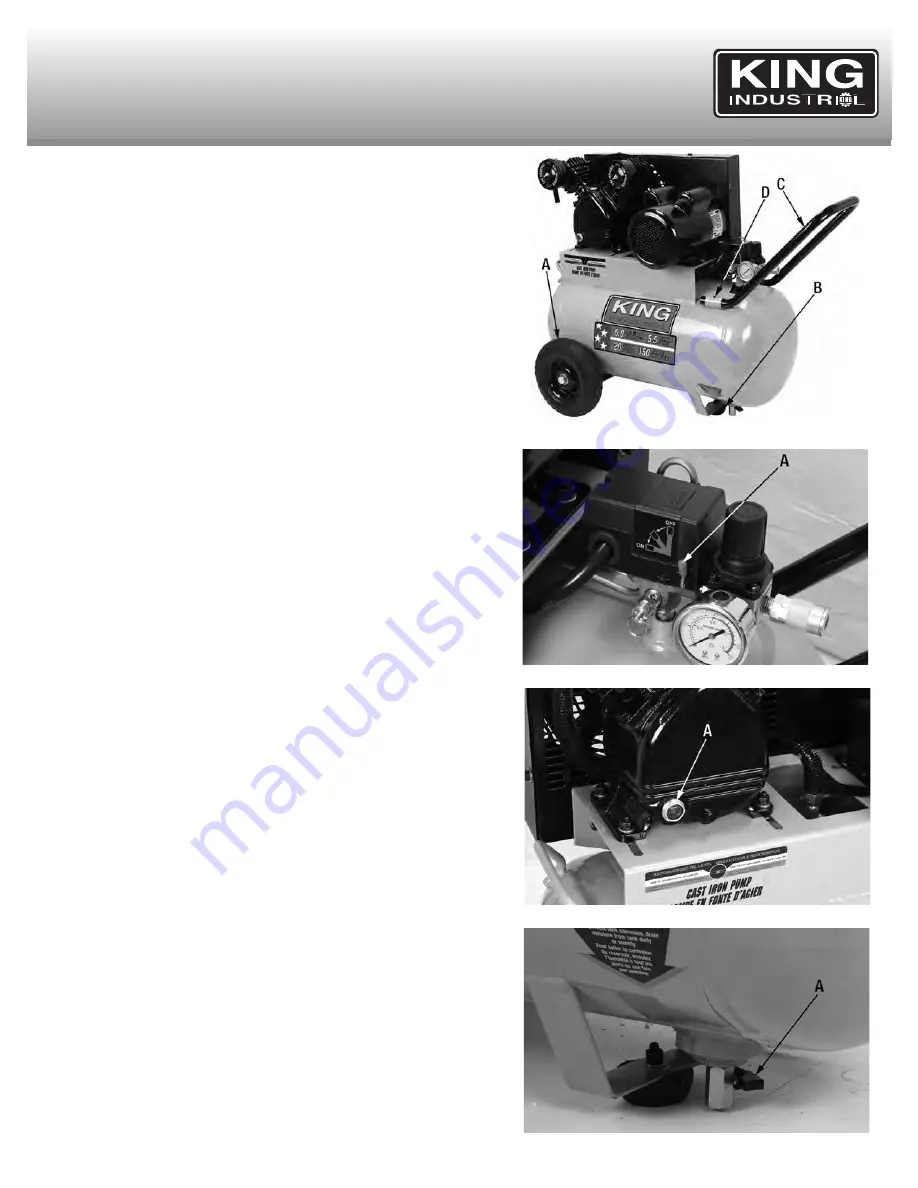

1) Make sure the pressure switch On/Off lever (A) Fig.4 is in the “OFF”

position as shown.

2) Plug the power cord into a grounded 120V branch circuit receptacle.

3) Make sure the oil level in the crankcase reaches the centre dot of the oil

sight glass (A) Fig.5, refer to maintenance section for instructions on

filling the crankcase with oil.

4) Open the drain valve lever (A) Fig.6, turn it counterclockwise, this will

prevent air pressure build-up in the tank.

5) Move the pressure switch On/Off lever (A) Fig.4 down to “ON/AUTO”

position. The compressor will start.

6) Run the compressor for 15 minutes. Make sure the drain valve is open

and there is no tank pressure build-up (tank pressure gauge at zero).

7) After 15 minutes, close the drain valve by turning it clockwise. The air

receiver will fill tank to cut-out pressure and the motor then will stop. The

air compressor is now ready for use.

FIGURE 3

FIGURE 4

FIGURE 5

FIGURE 6