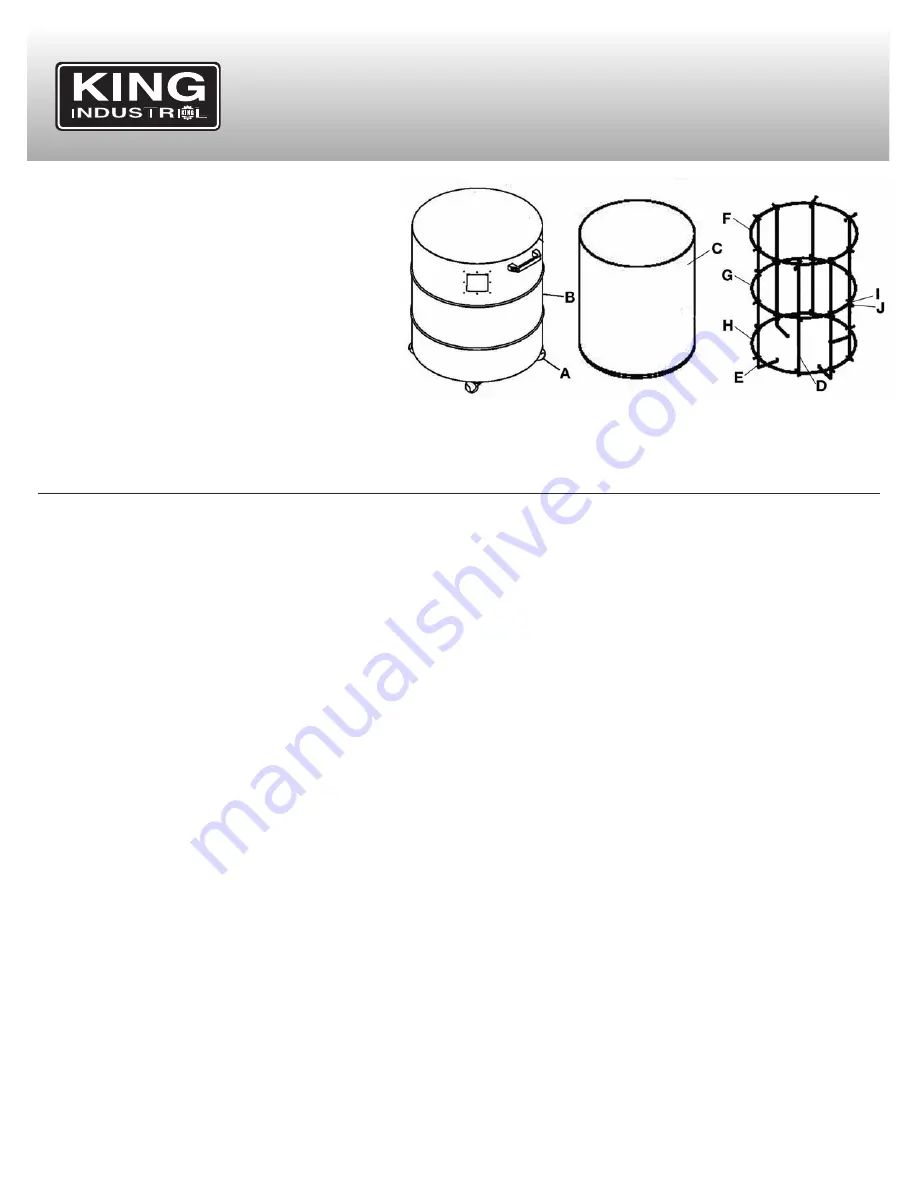

AsseMbly & MAIntenAnce

14. Install the wheel castors (A) Fig.10 to the bottom of the

drum (B).

15. Position the large plastic drum bag (C) inside the drum

(B).

16. Assemble the drum bag frame as shown in Fig.10.

Assemble the straight bars (D) and angled bars (E) to the

top ring (F), middle ring (G) and bottom ring (H) using

pan head screws (I) and hex. nuts (J).

17. Position the drum bag frame inside the drum to keep the

plastic bag shape in the negative pressure environment

of the cyclone drum. Once the drum bag is full, remove

the frame and dispose of waste.

FIGure 10

MAIntenAnce

cAnIster FIlter

For best performance, it is recommended on a regular basis to disloge dust from the inside of the canister filter, this is done by turning the

canister filter handle (F) Fig.8.

Motor

Excessive dust in the motor could cause excessive heat. Every effort should be made to prevent foreign material from entering the motor. A

visual inspection should be made at frequent intervals. Accumulations of dry dust can usually be blown out to prevent the interference with

normal motor ventilation. To remove dust, blow off motor with a low pressure air hose.

The operator performing this cleaning function should wear safety glasses and a filter mask. If any servicing (other than the above cleaning)

becomes necessary, it should be performed by an authorized service centre.

cAutIon:

WEARING A PARTICLE MASK/RESPIRATOR FOR PROTECTION AGAINST FINE DUST PARTICLES DURING CLEANING IS

HIGHLY RECOMMENDED.

Use the proper type of hose to connect the cyclone dust collector to the machine being operated. A dryer vent hose is not acceptable for this

purpose.

rePlAceMent druM bAGs And cAnIster FIlter bAG

A 6pc. kit including 5 drum bags and 1 canister filter bag (model: KDCB-63) is available, contact your distributor of King Canada products for

more information.