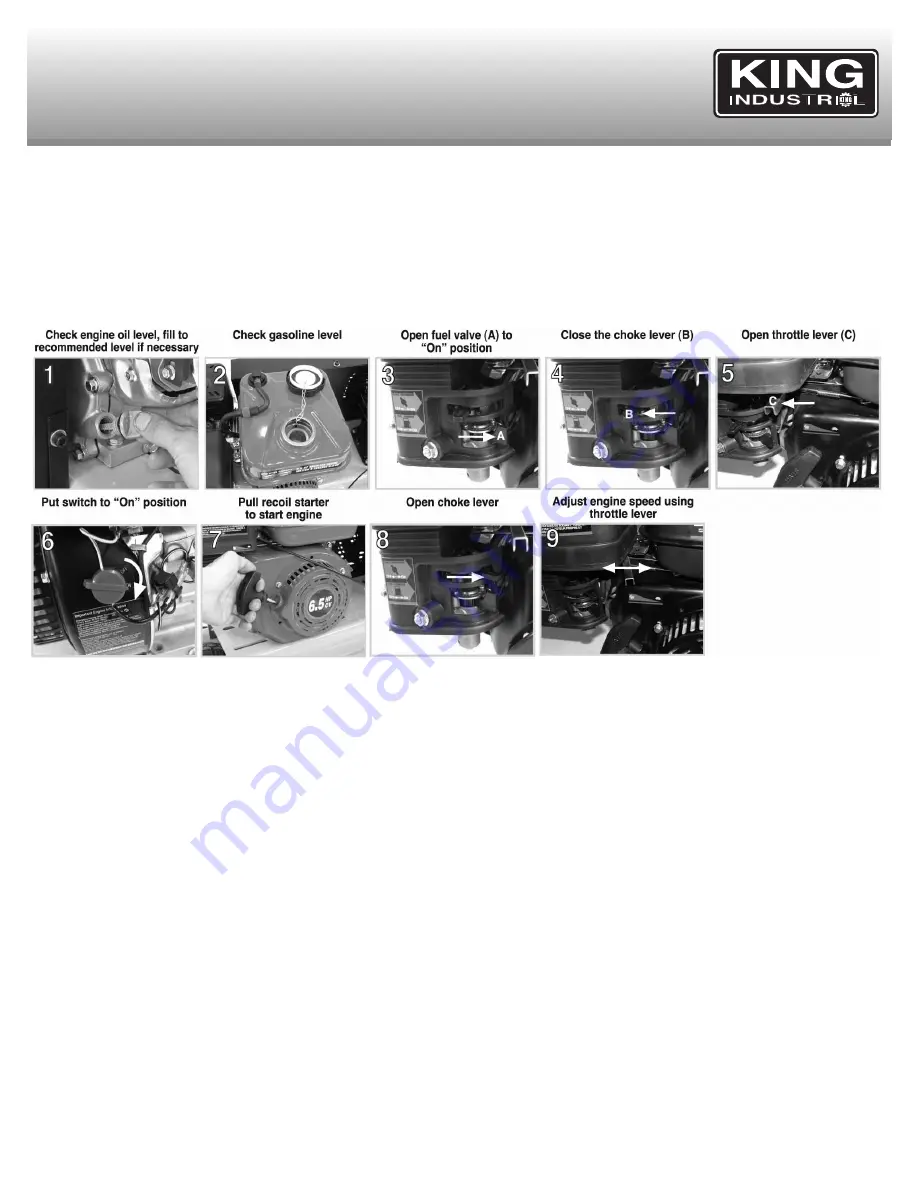

STARTING PROCEDURES

STARTING YOUR ENGINE

WARNING! Do not adjust or attempt maintenance of engine without consulting an authorized service center.

Never run engine indoors or in enclosed, poor ventilated areas, engine exhaust contains carbon monoxide, an

odorless and deadly gas!

To safely start your engine, follow these steps: (Fig.5)

Note: No choke is required on warm engines. Pull the recoil starter handle until resistance is felt, then pull it out with a rapid full arm stroke. Let

the starter rope rewind slowly, repeat if necessary. Allow engine to run at no load for 5 minutes upon each initial start-up to allow engine to

stabilize.

IF ENGINE OIL LEVEL IS TOO LOW, ENGINE WILL NOT START. CHECK OIL LEVEL AND ADD IF NECESSARY.

STOPPING PROCEDURES

STOPPING YOUR ENGINE

1) Move the throttle lever (refer to step 9, Fig.5) towards the right.

2) Turn the engine switch (refer to step 6, Fig.5) to the “OFF” position (upwards).

3) Close the fuel shut-off valve (refer to step 3, Fig.5) by moving it towards the left.

BREAK-IN PERIOD

To ensure proper engine operation, as well as extend the life of the engine, the following break-in instructions must be followed. The first 20 hours

of operation are the most important.

For the first 3 hours of operation:

• Do not apply a heavy load.

• Do not operate engine at maximum speed.

After 20 hours of operation:

• Change engine oil.

Figure 5

STARTING & STOPPING PROCEDURES