98

17. Daily Maintenance Operation

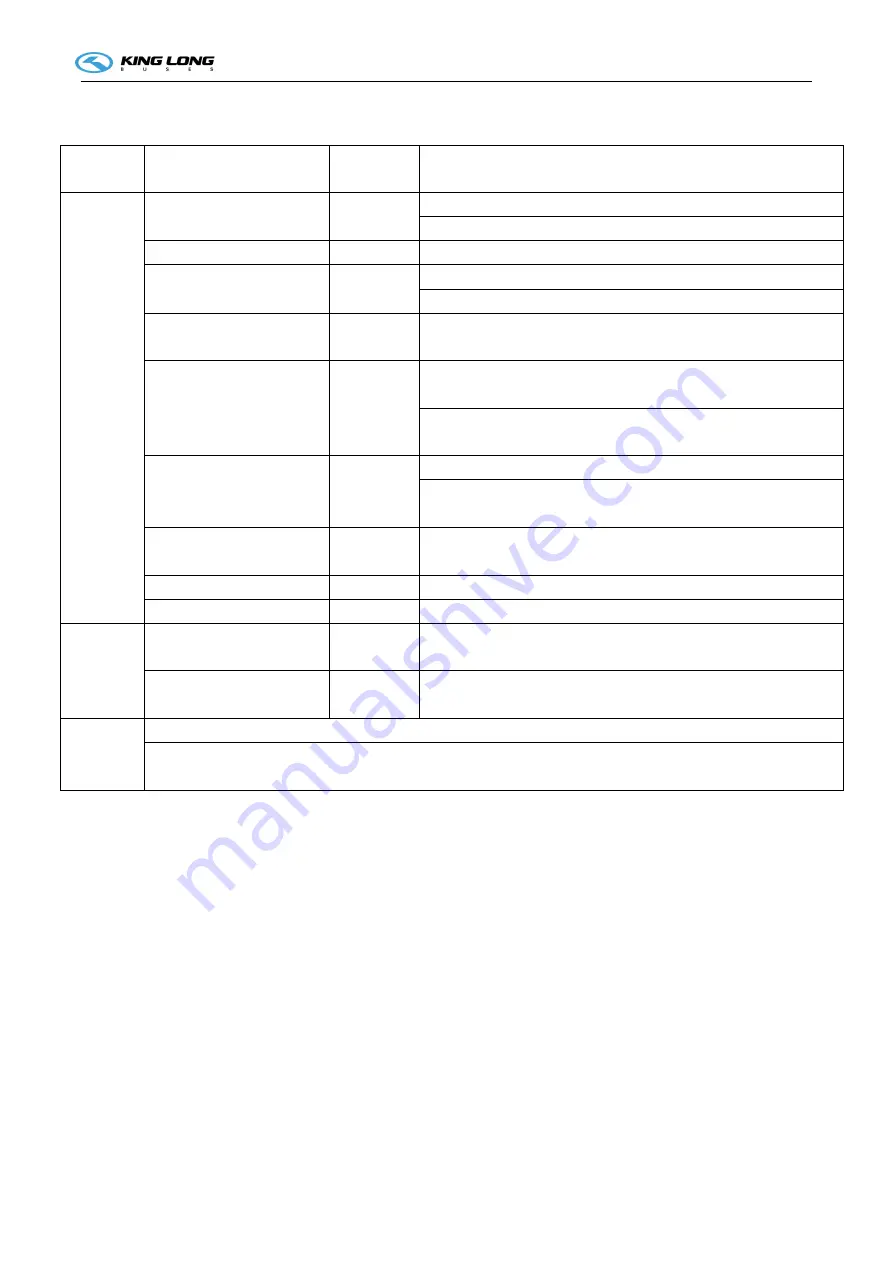

18. Maintenance period chart

For the Maintenance period charts please see the following charts for reference.

System

Item

Operation

Technical requirement

Engine

Air cleaner

Check

No leakage, damage, and crack.

Clips without looseness.

Fuel-water separator

Drain

Release the water and fouling

Cooling fan

Inspect

Do not pull or lever the cooling fan for starting the engine.

No crack, looseness, bend or damage.

air inlet/ outlet piping

Maintenance

check

Pipes without wear and damage, clips without looseness, prevent

the air leakage.

Coolant level

Check

Do not remove the water tank cover, unless the temperature is less

than 50

℃

, otherwise, it’s dangerous for operator

Do not add the cold coolant into the hot engine, unless the engine

temperature is less than 50

℃

Engine oil level

Check /

correct

Do not start engine when oil level less than “L” or more than “H”.

Vehicle parking level, check the oil after engine stops for 5

minutes

Drive belt

Check /

correct

No across crack, wear or material break off

Crankcase breather tube

Check

Check the breather tube in cold winter, cleanup the ice blocking.

Engine and Accessories

Check

No damage and crack

Air

suspension

Vehicle body

Check

Observe the vehicle body whether tilt or not, the air spring (or

piping) of one side is leaky if this side is lower.

The air springs

Check

If hear the sound of leaking obviously, we can deal with the

problem after confirming the specific leaky location

Training

1.Correct operation: no neutral speed skidding; no idle speed running of engine for a long time

2.Correct maintenance: replace oil, oil filter element, diesel filter element, transmission, axle, angle

transmission system periodically, clean and replace air filter element periodically