Maintenance and service

M-13

Periodical maintenance and operation items and regulations

Periodical maintenance of each class: do maintenance during each interval or certain miles .

Special instruction

: if assembly instruction requires different oil replace period, please follow the

instruction’s requirement on maintenance period and operation. If else please refer to this manual for

maintenance requirement.

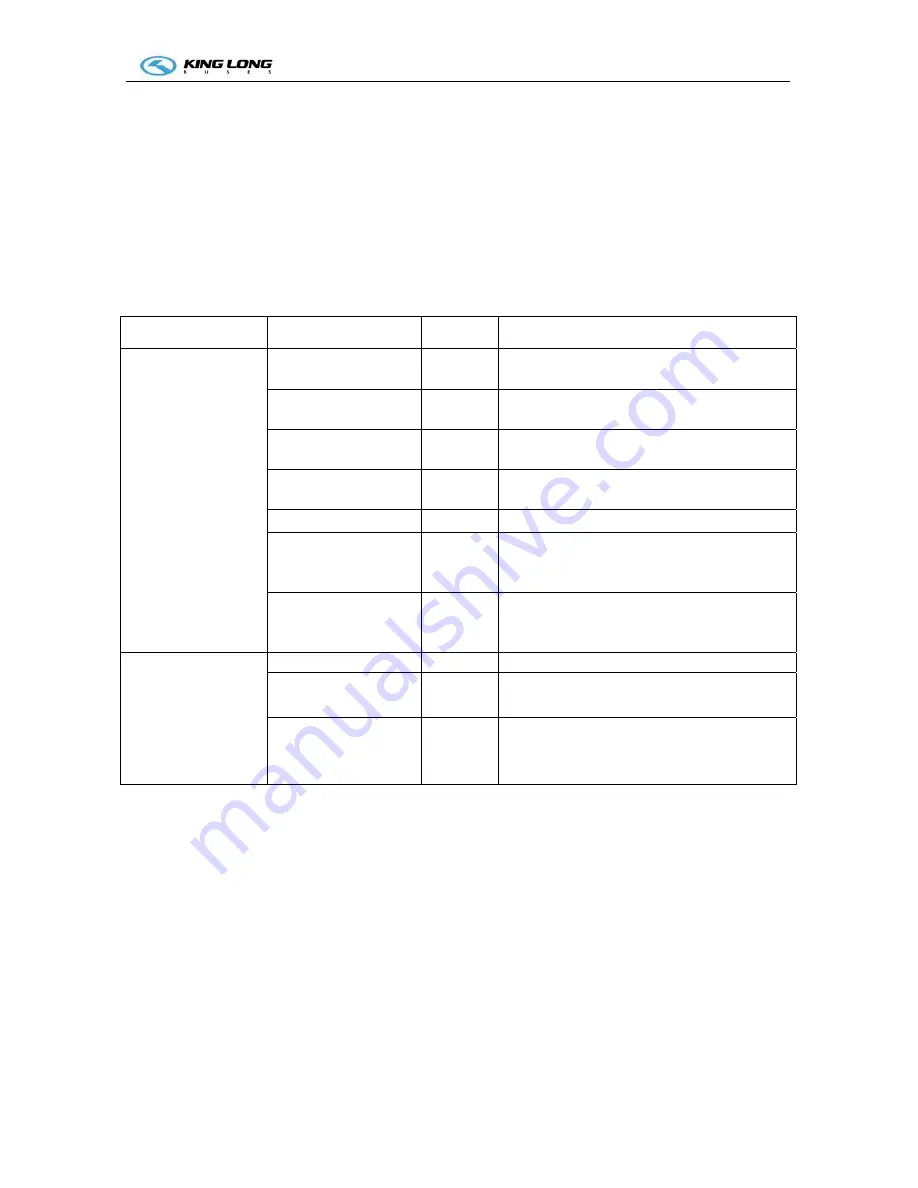

Maintenance operation and regulation every 5000km or 1 month depend on whichever occurs first.

Maintenance operation and regulation every 5000km

System Item

Operation Technical

requirement

Steering system

Working condition

Check

Steering wheel max free rotation at middle

10 degrees

redirector auxiliary

oil and filter element

Check

Below 10

℃

use DEXRON-II; above 10

℃

use C-3/10W

Fix bolts of each

place

Fasten

Each fastening bolts not loosening, steering

arm not loosening, steering wheel swift,

Ball head

Lubricate

Each turning ball head not loosening, no

clogging, clearance normal

ZF series

Maintenance Free, refer to ZF TE-ML09

GX85, GX 100, ZJ

100C

Check

N32 which manufactured by Shanghai oil

refining factory or ATF or related products

which produced.

IPS40-SB8575D

series

Check

Environment temperature >1

0℃,

adopt CD

level 15W/40 oil; Environment temperature

<1

0℃,

adopt No.8 hydraulic drive fluid.

Transmission

(

QJ series

mechanism or

automatic gearbox

)

Transmission fix bolt

Fasten

Transmission and

Accessories

Check

No leakage, operation organization effective,

no abnormal sound, wrong gear engagement.

Lubricant oil

Change

Refer to ZF TE-ML 20, oil change rely on

180,000KM or 3 years whichever comes

first.

Summary of Contents for XMQ6127 series

Page 18: ...Operation Instruction CI 1 Figure 17 Set MotPPR Figure 18 Clear Trip A Figure 19 Clear Trip B...

Page 32: ...Operation Instruction P A 1 2 Control panel operation...

Page 33: ...Operation Instruction P A 1...

Page 34: ...Operation Instruction P A 1...

Page 35: ...Operation Instruction P A 1...

Page 36: ...Operation Instruction P A 1...

Page 41: ...Operation Instruction 0 G 1 1 1 2 2 Pushbutton Settings...

Page 42: ...Operation Instruction 0 G 1 1 2 Starting the Engine 1 3 Selecting the Gear...

Page 43: ...Operation Instruction 0 G 1 1 4 Setting Off 1 5 Driving Ranges...

Page 44: ...Operation Instruction 0 G 1 1 5 1 Downhill Travel 1 5 2 Downhill Travel 1 5 3 Kickdown...

Page 46: ...Operation Instruction 0 G 1 1 6 Stopping Parking...

Page 51: ...Operation Instruction 0 G 1 1 11 1 Limp Home Mode 1 12 Auxiliary Control Unit...

Page 52: ...Operation Instruction 0 G 1 1 12 1 Operating Instructions for the Auxiliary Control Unit...

Page 53: ...Operation Instruction 0 AB 1 WABCO ABS BASIC INTRODUCTION...

Page 54: ...Operation Instruction 0 AB 1...

Page 55: ...Operation Instruction 0 AB 1...

Page 56: ...Operation Instruction 0 AB 1...

Page 57: ...Operation Instruction 0 AB 1...

Page 58: ...Operation Instruction 0 EC 1 ECAS System Introduction 1 System introduction...

Page 59: ...Operation Instruction 0 EC 1 3 System function...

Page 60: ...Operation Instruction 0 EC 1...

Page 77: ...Operation Instruction 0 E 1 CAN bus module...

Page 158: ...Appendix A 4 Air braking schematic diagram...

Page 159: ...A 5 Electric schematic diagram of the complete vehicle 1...

Page 160: ...A 6 Electric schematic diagram of the complete vehicle 2...

Page 161: ...A 7 Electric schematic diagram of the complete vehicle 3...

Page 162: ...A 8 Electric schematic diagram of the complete vehicle 4...