Maintenance and service

M-17

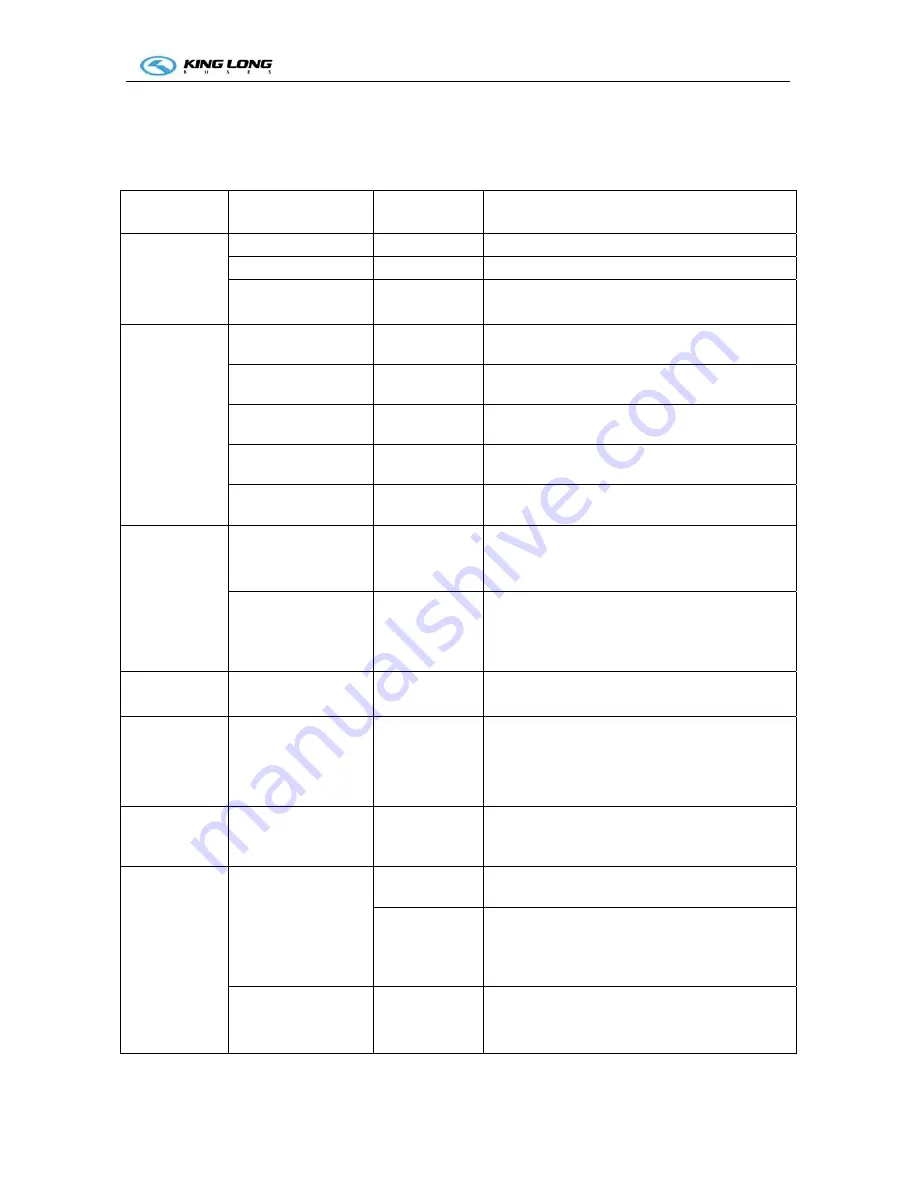

Maintenance operation and regulation every 20000km or 5 months depend on whichever occurs first.

Every 20000km include every 10000km maintenance operation

System Item

Operation

Technical

requirement

Engine

Fuel filter

Replace

Replace fuel filter element accordingly

Engine oil

Replace

Replace and fill oil level within required range

Coolant system –

anti-freezing

Check Check

the

density of anti-freezing

Propeller shaft

D

ust-proof cover

Check

Dust-proof cover without crack, damage, clip

reliable, bracket no loosening

Universal joint

condition

Check

Universal joint without loosening, no block

abnormal sound

Propeller shaft

bracket

Check

Propeller shaft bracket no loosening, screw torque

120

~

140Nm

Middle bearing

clearance

Check

Middle bearing clearance no more than 3mm

Lubricate

Lubricate

Lubricate each butter nozzle with 2# lithium

lubricant grease

Steering system

GX85, GX 100, ZJ

100C

Change oil and

filter core of

oil tank

N32 which manufactured by Shanghai oi

refining factory or ATF or related products which

produced.

IPS40-SB8575D

series

Change oil and

filter core of

oil tank

Environment temperature >1

0℃,

adopt CD leve

15W/40 oil;

Environment temperature <1

0 ℃ ,

adopt No.8

hydraulic drive fluid

Front axle

Toe-in of front

wheel

Not applicable

Radial-ply tire: 0

~

+2mm

Rear axle

(

DF

& FS series

)

Final drive

Not applicable

From injection hole into final drive filling

Parathion-type 90 heavy-duty gear oil (GL-5)

to the face.

(

for first 1500km, than change for

every 24,000km

)

The leaf

suspension

Not

applicable

Not loosening, crack, fracture, misplacement,

screw U bolt, front 196

~

294Nm, rear 343

~

392Nm

The air

suspension

The liner bushing of

the rod assembly

Change

The liner bushing is relative sliding with the bal

head

Change

The liner bushing is knocked to bend and the

tighten bolts of the adjustable rod are becoming

invalid which result to the threads of the ball head

and the steel pipe damaged.

The rubber ball joints

Change

The crack on the surface of the rubber is very

serious. The depth of the crack is up to 2mm and

the length of it is up to 8mm

Summary of Contents for XMQ6127 series

Page 18: ...Operation Instruction CI 1 Figure 17 Set MotPPR Figure 18 Clear Trip A Figure 19 Clear Trip B...

Page 32: ...Operation Instruction P A 1 2 Control panel operation...

Page 33: ...Operation Instruction P A 1...

Page 34: ...Operation Instruction P A 1...

Page 35: ...Operation Instruction P A 1...

Page 36: ...Operation Instruction P A 1...

Page 41: ...Operation Instruction 0 G 1 1 1 2 2 Pushbutton Settings...

Page 42: ...Operation Instruction 0 G 1 1 2 Starting the Engine 1 3 Selecting the Gear...

Page 43: ...Operation Instruction 0 G 1 1 4 Setting Off 1 5 Driving Ranges...

Page 44: ...Operation Instruction 0 G 1 1 5 1 Downhill Travel 1 5 2 Downhill Travel 1 5 3 Kickdown...

Page 46: ...Operation Instruction 0 G 1 1 6 Stopping Parking...

Page 51: ...Operation Instruction 0 G 1 1 11 1 Limp Home Mode 1 12 Auxiliary Control Unit...

Page 52: ...Operation Instruction 0 G 1 1 12 1 Operating Instructions for the Auxiliary Control Unit...

Page 53: ...Operation Instruction 0 AB 1 WABCO ABS BASIC INTRODUCTION...

Page 54: ...Operation Instruction 0 AB 1...

Page 55: ...Operation Instruction 0 AB 1...

Page 56: ...Operation Instruction 0 AB 1...

Page 57: ...Operation Instruction 0 AB 1...

Page 58: ...Operation Instruction 0 EC 1 ECAS System Introduction 1 System introduction...

Page 59: ...Operation Instruction 0 EC 1 3 System function...

Page 60: ...Operation Instruction 0 EC 1...

Page 77: ...Operation Instruction 0 E 1 CAN bus module...

Page 158: ...Appendix A 4 Air braking schematic diagram...

Page 159: ...A 5 Electric schematic diagram of the complete vehicle 1...

Page 160: ...A 6 Electric schematic diagram of the complete vehicle 2...

Page 161: ...A 7 Electric schematic diagram of the complete vehicle 3...

Page 162: ...A 8 Electric schematic diagram of the complete vehicle 4...