Maintenance and service

M-20

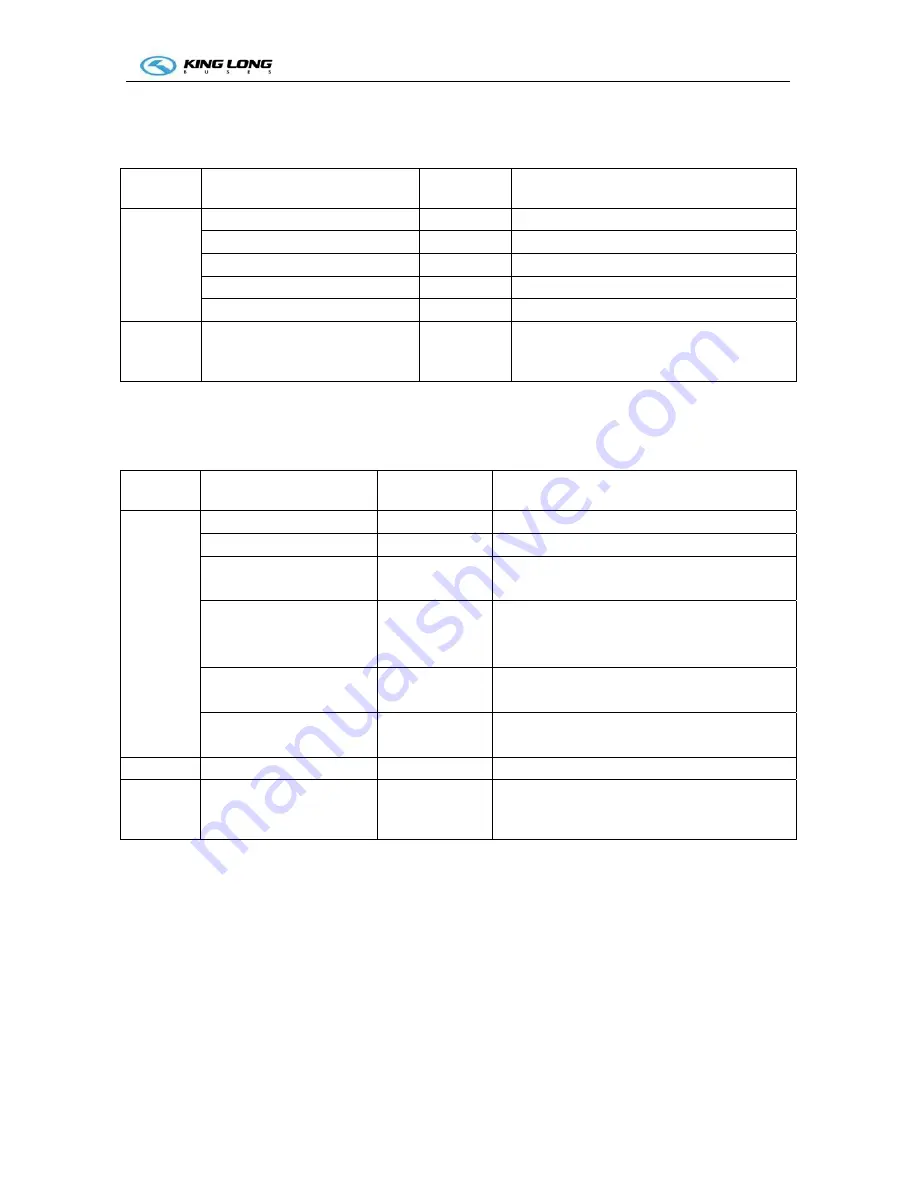

Maintenance operation and regulation every 40000km or 8 months depend on whichever occurs first.

Every 40000km include every 20000km maintenance operation

System Item

Operation Technical

requirement

Engine

Drive belt, Cooling fan belt tension Check/adjust

Check each belt without loosening or damage

Cooling fan bearing and bolt

Check/adjust No damage, fouling, loosening

Belt tension pulley bearing

Check/adjust No damage, fouling, loosening

Cylinder cover bolt

Check/adjust No damage, loosening

Air dryer

Replace

Replace air dryer

Suspension

Leaf spring bushing

Not

applicable

Clearance between leaf spring bush and pin

normal, no abnormal abrasion, bush not

crack, lubrication normal

Maintenance operation and regulation every 80000km or 12 months depend on whichever occurs first.

Every 80000km include every 40000km maintenance operation

System Item

Operation

Technical

requirement

Engine

Thermostats Replace

Fuel roughing filter

Replace

Cooling system

Release/ clean/

add

Radiator

Check

Radiator without leakage, damage, fouling.

Hose without damage, clips without loosen or

damage.

Engine suspending

Check/fasten

Connection reliable, firm, soft mat no distortion

layer or crack

Overhead set- valves and

injectors

Measure

Valve clearance within required range

Clutch

Clutch brake fluid level

Not applicable

Compound brake fluid

The leaf

suspension

leaf spring bushing

Not applicable

Clearance between leaf spring bushing and pin

normal, no abnormal abrasion, bushing without

crack, lubrication normal

Summary of Contents for XMQ6127 series

Page 18: ...Operation Instruction CI 1 Figure 17 Set MotPPR Figure 18 Clear Trip A Figure 19 Clear Trip B...

Page 32: ...Operation Instruction P A 1 2 Control panel operation...

Page 33: ...Operation Instruction P A 1...

Page 34: ...Operation Instruction P A 1...

Page 35: ...Operation Instruction P A 1...

Page 36: ...Operation Instruction P A 1...

Page 41: ...Operation Instruction 0 G 1 1 1 2 2 Pushbutton Settings...

Page 42: ...Operation Instruction 0 G 1 1 2 Starting the Engine 1 3 Selecting the Gear...

Page 43: ...Operation Instruction 0 G 1 1 4 Setting Off 1 5 Driving Ranges...

Page 44: ...Operation Instruction 0 G 1 1 5 1 Downhill Travel 1 5 2 Downhill Travel 1 5 3 Kickdown...

Page 46: ...Operation Instruction 0 G 1 1 6 Stopping Parking...

Page 51: ...Operation Instruction 0 G 1 1 11 1 Limp Home Mode 1 12 Auxiliary Control Unit...

Page 52: ...Operation Instruction 0 G 1 1 12 1 Operating Instructions for the Auxiliary Control Unit...

Page 53: ...Operation Instruction 0 AB 1 WABCO ABS BASIC INTRODUCTION...

Page 54: ...Operation Instruction 0 AB 1...

Page 55: ...Operation Instruction 0 AB 1...

Page 56: ...Operation Instruction 0 AB 1...

Page 57: ...Operation Instruction 0 AB 1...

Page 58: ...Operation Instruction 0 EC 1 ECAS System Introduction 1 System introduction...

Page 59: ...Operation Instruction 0 EC 1 3 System function...

Page 60: ...Operation Instruction 0 EC 1...

Page 77: ...Operation Instruction 0 E 1 CAN bus module...

Page 158: ...Appendix A 4 Air braking schematic diagram...

Page 159: ...A 5 Electric schematic diagram of the complete vehicle 1...

Page 160: ...A 6 Electric schematic diagram of the complete vehicle 2...

Page 161: ...A 7 Electric schematic diagram of the complete vehicle 3...

Page 162: ...A 8 Electric schematic diagram of the complete vehicle 4...