16

Step 3: Setting Control Dial

This system is designed to work effectively with a variety of pool equipment as long as the following procedures are followed.

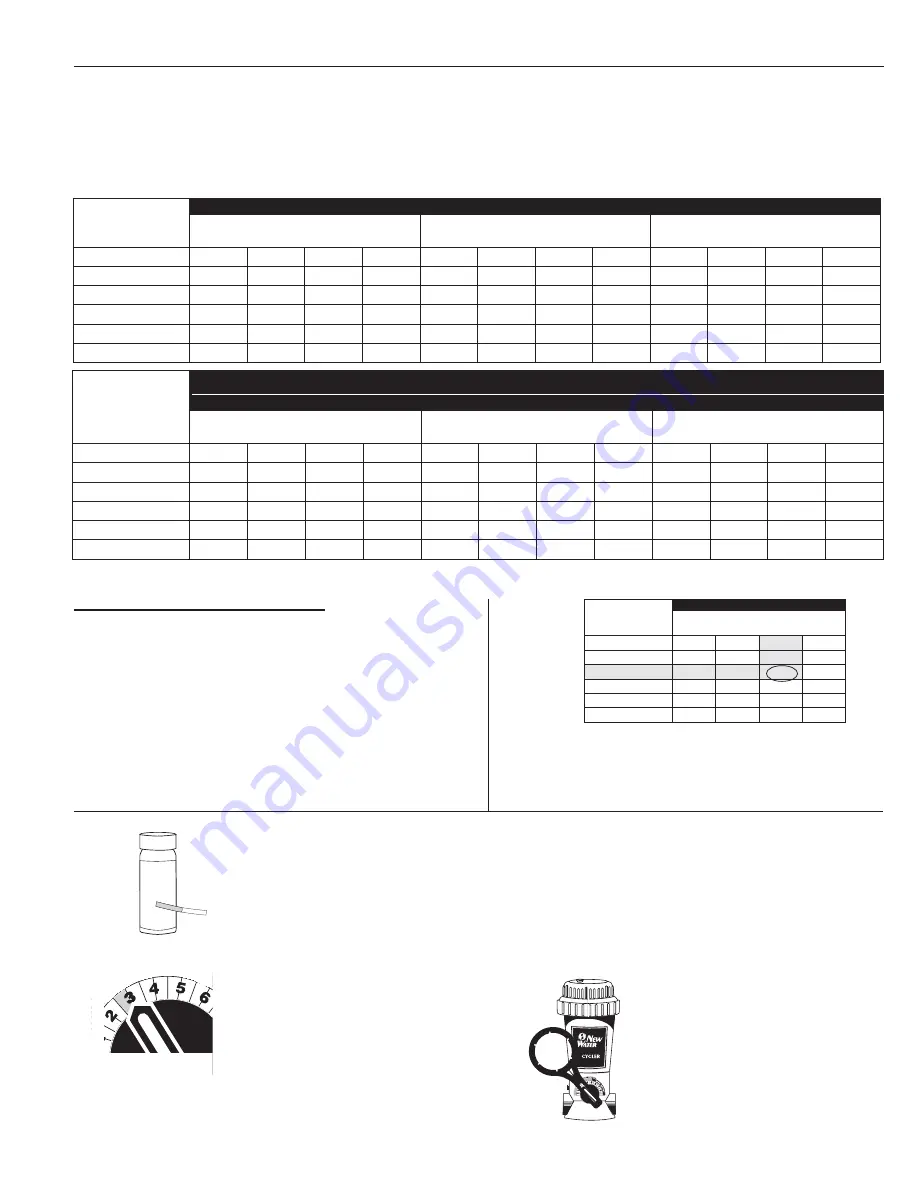

Set control dial on New Water Cycler by matching up the parameters of your pool on the chart below. THIS IS A STARTING POINT

ONLY and may need to be adjusted to fi t your individual pool needs. See #2 below for adjusting directions.

IMPORTANT:

If using a multi-speed pump, pump-run times of at least 6 hours per day at high speed are recommended for proper

performance.

If running the pump at low speed only or on high speed less than 6 hours, please follow the 24 hour low-

speed directions below.

24 HOUR, LOW-SPEED PUMP RUN TIME

In order to ensure proper performance when running the pump on

low speed for 24 hours per day or high speed less than 6 hours

per day, bleed the air while the pump is on by unscrewing the cap

or back knob until water appears. Then screw the knob back in.

Repeat this process each time the cap is removed for any reason.

Set the control dial at 6 and follow the adjustment directions in

Step 2 to determine the correct setting for your pool.

For the fi rst week, test the pool water

daily for free chlorine to ensure correct

dial setting. Continue to test weekly

throughout the season.

Use the handle end of cap tool if the

dial is hard to turn.

After each testing, adjust the dial up

by 1/2 increment if the free chlorine

reading has dropped or down by

1/2 increment if the reading has

risen. Continue this process each

day until the reading stabilizes at

your desired level between 1.0- 3.0

ppm. Remember to adjust dial by 1/2

increments only.

1.

2.

4EST

3TRIPS

Pool

Strips

Test

and

Spa

MODEL 120

POOL SIZE

Gallons Diameter

8 HOUR PUMP RUN TIME

12 HOUR PUMP RUN TIME

24 HOUR PUMP RUN TIME

PUMP SIZE

1/2 hp 3/4 hp 1 hp 1 1/2 hp

PUMP SIZE

1/2 hp 3/4 hp 1 hp 1 1/2 hp

PUMP SIZE

1/2 hp 3/4 hp 1 hp 1 1/2 hp

7,000 (18’)

4.5

4.0

3.5

3.0

2.5

2.0

1.0

3.0^

1.5

1.0

1.0

2.0^

9,000 (21’)

5.0

4.5

4.0

3.5

3.0

2.5

2.0

3.5^

2.0

1.5

1.0

2.5^

12,000 (24’)

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

2.5

2.0

1.5

3.0^

18,000

NR

5.5

5.0

4.5

4.0

3.5

3.0

2.5

3.0

2.5

2.0

1.5

20,000

NR

NR

5.5

5.0

4.5

4.0

3.5

3.0

3.5

3.0

2.5

2.0

25,000

NR

NR

6.0

5.5

5.0

4.5

4.0

3.5

4.0

3.5

3.0

2.5

MODEL 400

POOL SIZE

Gallons

SINGLE-SPEED PUMP OR HIGH-SPEED PUMP RUN TIME

6 HOUR PUMP RUN TIME

12 HOUR PUMP RUN TIME

24 HOUR PUMP RUN TIME

PUMP SIZE

3/4 hp 1 hp 1 1/2 hp 2 hp

PUMP SIZE

3/4 hp 1 hp 1 1/2 hp 2 hp

PUMP SIZE

3/4 hp 1 hp 1 1/2 hp 2 hp

7,000

3.5

3.0

2.5

2.5^

2.5

2.0

3.5^

3.0^

1.0

3.0^

2.5^

2.0^

9,000

4.0

3.5

3.0

2.5

3.0

2.5

2.0

3.5^

2.0

3.5^

3.0^

2.5^

12,000

4.5

4.0

3.5

3.0

3.5

3.0

2.5

2.0

2.5

2.0

1.0

3.0^

18,000

NR

4.5

4.0

3.5

4.5

3.5

3.0

2.5

3.0

2.5

2.0

1.5

25,000

NR

NR

4.5

3.5

NR

4.5

3.5

3.0

3.5

3.0

2.5

2.0

30,000

NR

NR

5.5

4.5

NR

5.0

4.5

3.5

NR

3.5

3.0

2.5

^Bypass installation recommended. See “Installation Tips” on page 6

NR

- This pump size is not recommended for this size pool.

IMPORTANT:

Control dial settings in excess of these

recommendations could result in excess trichlor levels being

discharged into the pool. This can result in bleaching or

discoloration of areas around the pool inlet or in some cases

bleaching or discoloration of the entire pool liner or paint. In

addition, excess trichlor in the pool can create health hazards

to bathers.

EXAMPLE

Find your starting dial setting by matching up the parameters of your pool on

the above chart. An above ground pool with approximately 12,000 gallons,

with a 1 1/2 horsepower pump running 12 hours a day, would require a

starting setting of 2.5.

MODEL 400

POOL SIZE

Gallons

12 HOUR PUMP RUN TIME

PUMP SIZE

3/4 hp 1 hp 1 1/2 hp 2 hp

7,000

2.5

2.0

3.5^

3.0^

9,000

3.0

2.5

2.0

3.5^

12,000

3.5

3.0

2.5

2.0

18,000

4.5

3.5

3.0

2.5

25,000

NR

4.5

3.5

3.0

30,000

NR

5.0

4.5

3.5