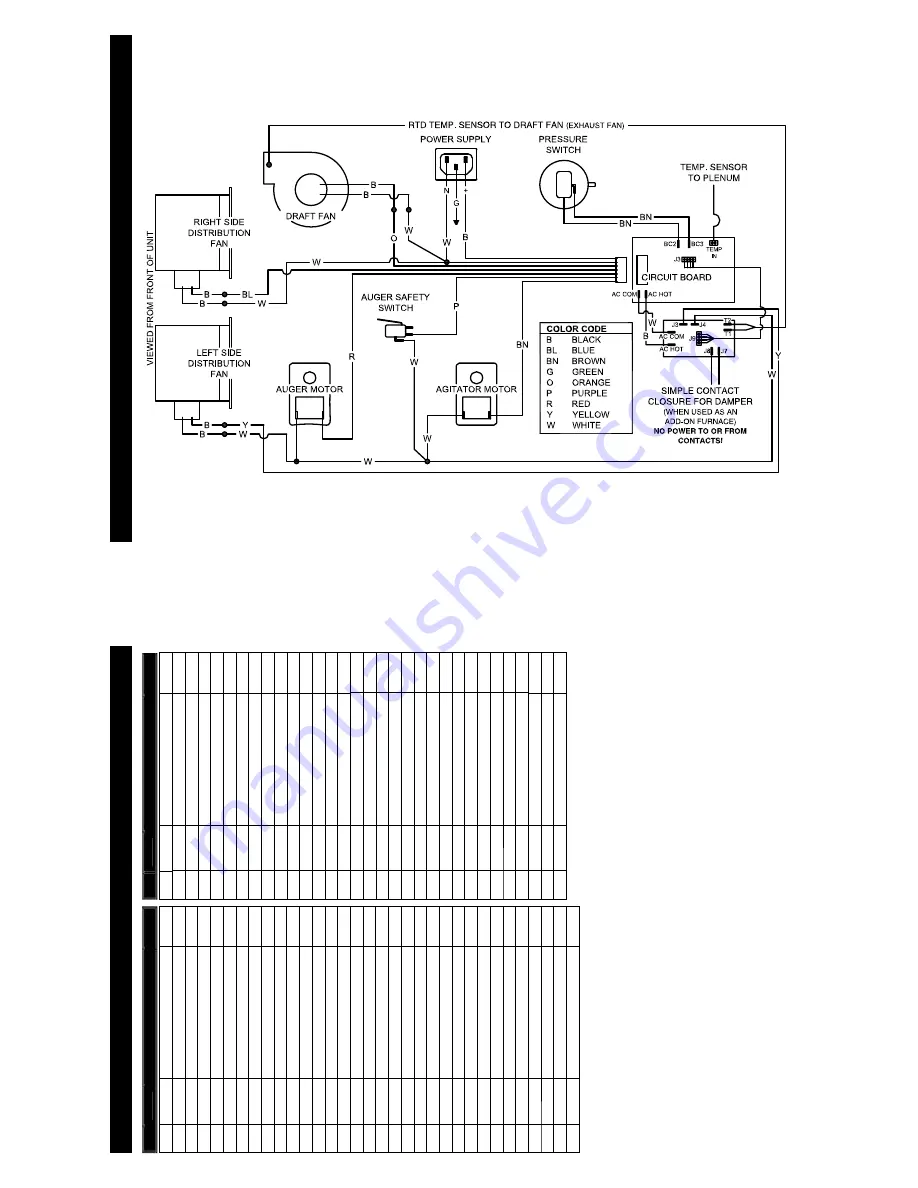

USSC

19

18

USSC

W

ir

in

g Diagra

m Amendmen

t

P

ar

ts L

ist

1

23786

Door Latch (C000022)

1

2

24179

Feed Door Handle

1

3

25427

Retainer

, Agitator

Motor

1

4

40501

Agitator

, Cast

1

5

69679

Assembly

, Feed Door (Blank)

1

6

80461

Power Supply Cord

1

7

80462

Receptacle, 3 Prong

1

8

80488

Drive Motor (1.5 RPM CCW)

1

9

80495

120 CFM Blower

Assembly

1

10

80530

Blower

, Room 800CFM

2

1

1

80531

R

TD, Platinum

1

12

80549

Pressure Switch

1

13

80554

Assembly

, Controller PCB

1

14

80616

Wiring Harness, Main

1

15

80617

Wiring Harness, Room Blowers

1

16

83045A

\

!`[?[?^[^?

'&

2

17

83274

3/8-16 Lk Nut, Black

2

18

83529

Hairpin

1

19

83533

Roll Pin 1/8” Diameter x 7/8”

1

20

83551

1/4-20 Wing Nut, Brass

2

21

83564

Clamp, Hose-1/2, Self-Compen.

2

22

86620

Agitator Drive Shaft

1

23

881

1

1

Gasket, Agitator

Bracket

1

24

88123

Gasket, Blower 120CFM

1

25

88127

Blower Gasket

2

26

891

121

Hose, Silicone

2

27

891

135

Handle, Spring (LG-Nickel)

1

28

891

187

Bracket, Pressure Switch/PCB

1

29

25422M

Mounting Bracket for 3/4” Bushing

1

30

83534

Retaining Ring

3

31

891

132

Agitator Bushing

3

32

891284

Access Panel,

Agitator Motor

1

33

891296

T

ransition Duct, 10” Round

1

34

891331

Spring Handle-Brushed Nickel

1

35

891364

Hearth Plate

1

36

891374

Access Panel, Plenum

1

37

891423

Pin, Door Hinge

2

38

891445

Ash Pan

Assembly

1

39

891455

W

eldment, Burnpot

1

40

891461

Cover

, Exhaust Cleanout

1

41

891471

Lid W

eldment

1

42

891440

Cleanout, Ash

2

43

891262

1

44

891457

Cleanout, Ash

Lower

2

45

891485

W

eldment-Damper

1

46

89586

Auger Nipple

1

47

80501

Thermistor

, Long Lead

1

48

892066

T

op Cover W

eldment

1

49

25496

Cover

, Auger

1

50

891338

Assembly

, Mounting Bracket, Lid Switch

1

51

25495

Bracket, Drive Motor

1

52

891

189

Plate, T

op

Bushing

1

53

80529

Auger Motor

1

54

891

141

Auger

1

55

891

164

W

eldment, Auger

Housing

1

56

891

190

Plate, Bottom Bushing

1

57

891

169

Hose, Heater

2

58

891248

W

eld., Bot. Plate Retainer

1

59

892079

Side Panel, Left

1

60

892080

Side Panel, Right

1

61

892081

T

ransition, Exhaust Duct

1

62

892084

Access Panel, Back

1

63

892086

Blower Mount

1

64

892087

Access Panel, Blower

1

65

89603

Brass Connector

1

Key

Key

Key

Key

Part

Part

No.

No.

Part

Part

No.

No.

Desc

Desc

ript

ript

ion

ion

Desc

Desc

ript

ript

ion

ion

Qty

Qty

.

Qty

Qty

.

Key

Key

Key

Key

Part

Part

No.

No.

Part

Part

No.

No.

Desc

Desc

ript

ript

ion

ion

Desc

Desc

ript

ript

ion

ion

Qty

Qty

.

Qty

Qty

.

T

o

order repair parts,

you may visit the U. S. Stove website

or call (800) 750-2723