4

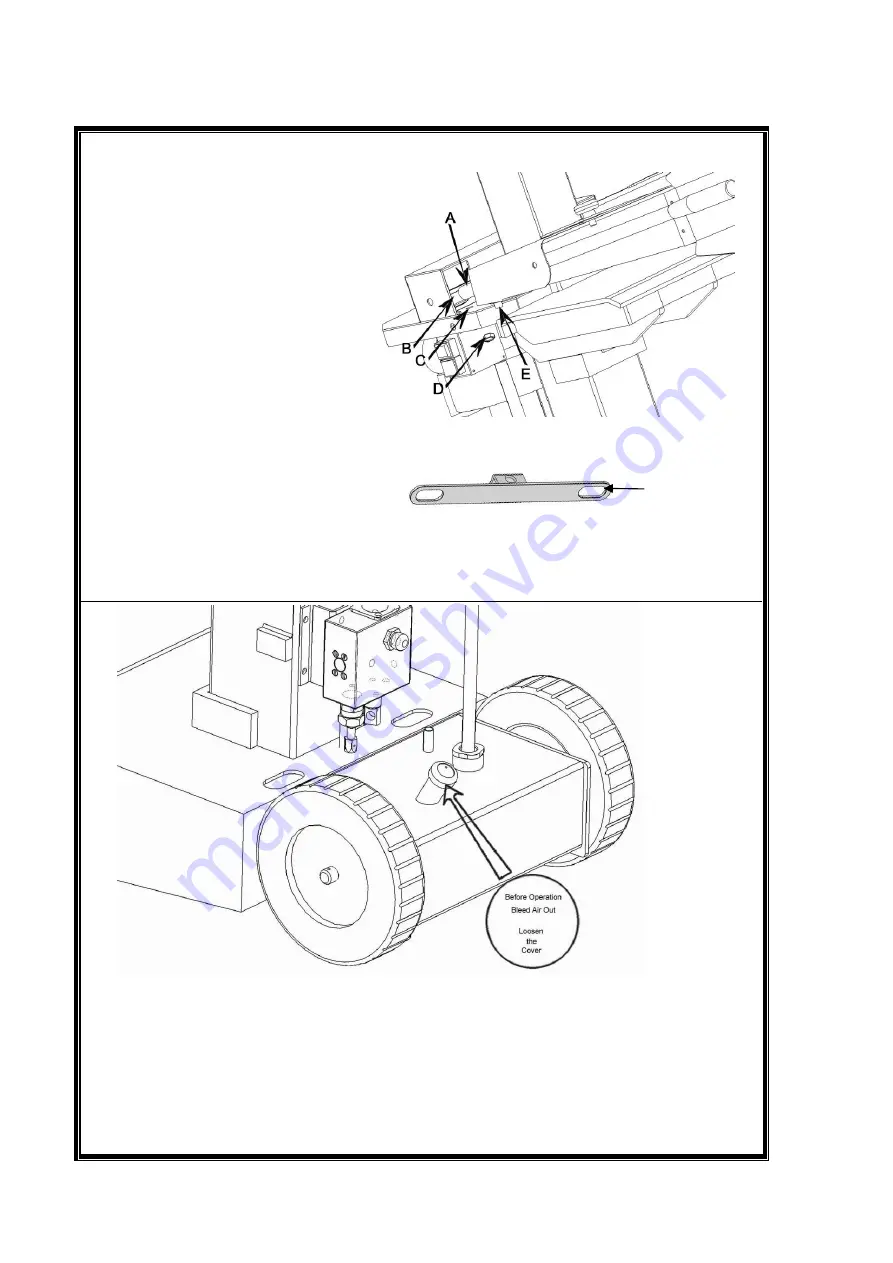

10 . Assembly of operation Handle with Guard

Put the head of operation

handle(A) into the hole

for flat steel

(

see below

)

inside the cover(B).

Put bolt M12x15(E)into

The hole (C), then fix it with nut

M12(D).

Flat Steel

Attention

: The operation handle guard should be assembled by trained

professional people or engineers.

11.

Bleed the air out of the Hydraulic system before starting the log splitter.

The Cover of the hydraulic oil tank should be loosened by some rotations

until air can go in and out of the oil tank smoothly.

Air flow thru the oil tank filler should be detectable during the operations.

Before moving the log splitter, make sure the cover of the oil tank is

Tightened to avoid oil leaking from this point.

Summary of Contents for LS10TG

Page 3: ...3 4 5 6 7 8 9 ...

Page 14: ...14 Hydraulic Diagram ...

Page 16: ...16 ...

Page 17: ...17 ...