06/07/20

7

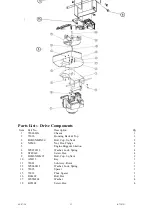

K7201G

WHEN

ASSEMBLING

YOUR

KGR7201I GARDEN RECYCLER

MAKE CERTAIN THE SPARK PLUG

WIRE IS DISCONNECTED AND

MOVED AWAY FROM THE SPARK

PLUG BEFORE PROCEEDING TO

ASSEMBLE THE UNIT.

1.

Set basic unit into a position where you can

attach the stand struts to the wheel axles.

Slide one strut all the way along each axle

end until they rest against the chassis.

2. Swing the hopper stand down until the

stand strut holes align with the holes in the

hopper stand. NOTE* The stand strut are to

be placed on the inside of the hopper stand.

Fasten the hopper stand to the stand struts

with 2x M8x25 bolts and M8 flange nuts.

3. Fit one Circlip to each inside Circlip groove

on the wheel axles; fit one washer to each

axle end then fit wheels to the axles. Fit

another washer to each axle end then

retain each wheel and washer with a

Circlip. Fit hubcaps to wheels.

4. Fit the chipper chute to the main

assembly-: Loosen the two M8 nuts at the

chute mounts, wind the nuts out till they

are flush to the end of the bolts. Remove

the bottom screen pin, lift the screen and

position the chipper chute above and over

the mounting area. Locate the top nut into

the keyhole slot on the chute. Hold the

chute up against the main assembly and

slide it down to locate the bottom

mounting bolt into the bottom slot.

Finger tighten the two nuts and fit

1xM8x25 cuphead bolt from the inside

of the chipper/shredder discharge area

into the third mounting hole in the

chute secure with 1x M8 flange nut,

tighten all three nuts. Replace the

bottom screen pin and tighten the

retaining bolt and nut.

5. Fit the discharge deflector as shown

using 4x M8x20 bolts, 4x 8mm I/D

washers and 4x M8 flange nuts.

BEFORE STARTING:

FILL FUEL TANK WITH UNLEADED FUEL AND CHECK ENGINE OIL LEVEL/TOP UP IF

NECESSARY. Refer to engine operator’s manual for correct oil specification and oil level

checking procedure.

WARNING:

IF PETROL IS ACCIDENTLY

SPILLED, MOVE THE GARDEN RECYCLER AWAY

FROM THE SPILL AREA, AVOID

CREATING ANY SOURCE OF IGNITION

UNTIL PETROL VAPORS HAVE

DISAPPEARED.