IDV26

Remote Receiver Location

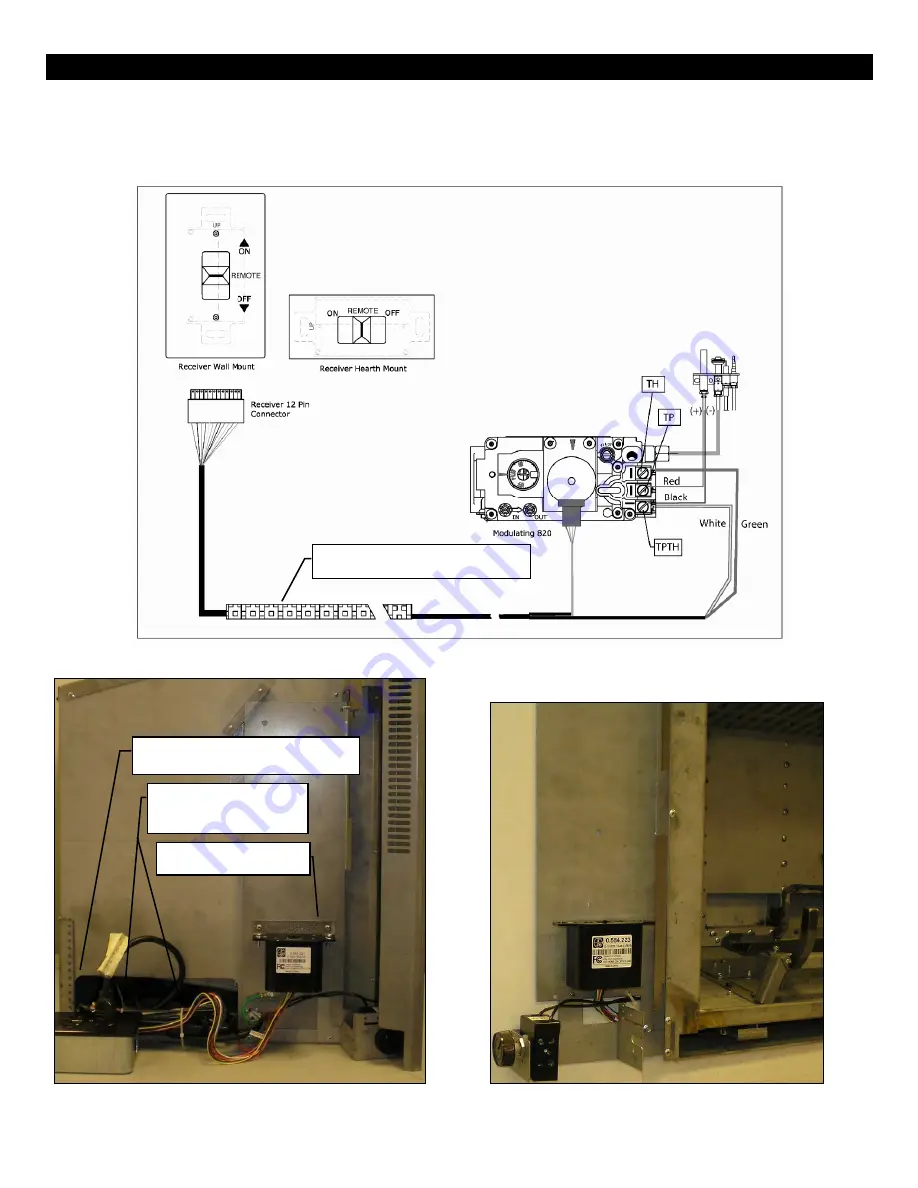

All Units

Connecting to the Gas Valve

The wiring harness for the Proflame GTM system has two wires labeled “TH” & “TPTH”. Connect the wires to the gas

valve as labeled. (TH to TH and TPTH to TPTH). Additionally there is a connector labeled “Motor”. Connect this “Motor”

connector to the stepper motor on the gas valve (if present).

Left Side of Fireplace

Components In (As Shipped)

Components Out Remote Receiver Location.

Route Wiring Harness

1001-P904SI

Under Fan Inside Fireplace.

Route Wiring Harness

1001-P904SI

Under Fan Inside Fireplace.

Restrain Harness With [2]

Zip Ties Through Holes

Provided in Fireplace.

Pull up Mount Tabs &

Mount Remote Receiver

28

Summary of Contents for Marquis IDV26

Page 15: ...I26SU UNIVERSAL SURROUND I26CVPF1 or I26CVPF3 I26CVPF2 or I26CVPF4 BOTTOM OF UNIT 15 ...

Page 45: ...I43CV I43CV3 I43US4736 Flat Custom Surround TO BE CUSTOM CUT AND BENT I43CV I43CV3 7 1 4 45 ...

Page 89: ...Gas Conversion for Modulator PART C 89 ...

Page 100: ...Proflame 2 Remote Control 100 ...

Page 102: ...102 ...