Problem7.

Temperature value are displayed

frequently.

Problem8.

Can’t set the temperature.

Problem9.

Soldering iron heats up continually, with

the indicator always lightening.

sensor element.

Check11. Is there a tip on the iron?

Assemble a tip on the iron.

Check12. Is the soldering iron cord broken?

See how to check the breakage of heating and

sensor element.

Check13. Is the item to be soldered too big?

Use a higher out power iron or ignore.

Check14. Locked the button on the panel.

Enter into setting the password.

If you have forgot the password:

Disassemble the Front panel (see parts list-station),

plug the power into a power supply, turn the

power switch on.

Press the “D-S” button inside PCB (see parts list).

The password will be resumed to “000”. Assembly

it in the reverse order of disassembly.

Check15. Is the sensor (with polarity) connected

oppositely?

Resolder the sensor wire.

Check16. Is the sensor short-circuited?

Replace the sensor.

Checking for Breakage of the Heating Element and Sensor Element

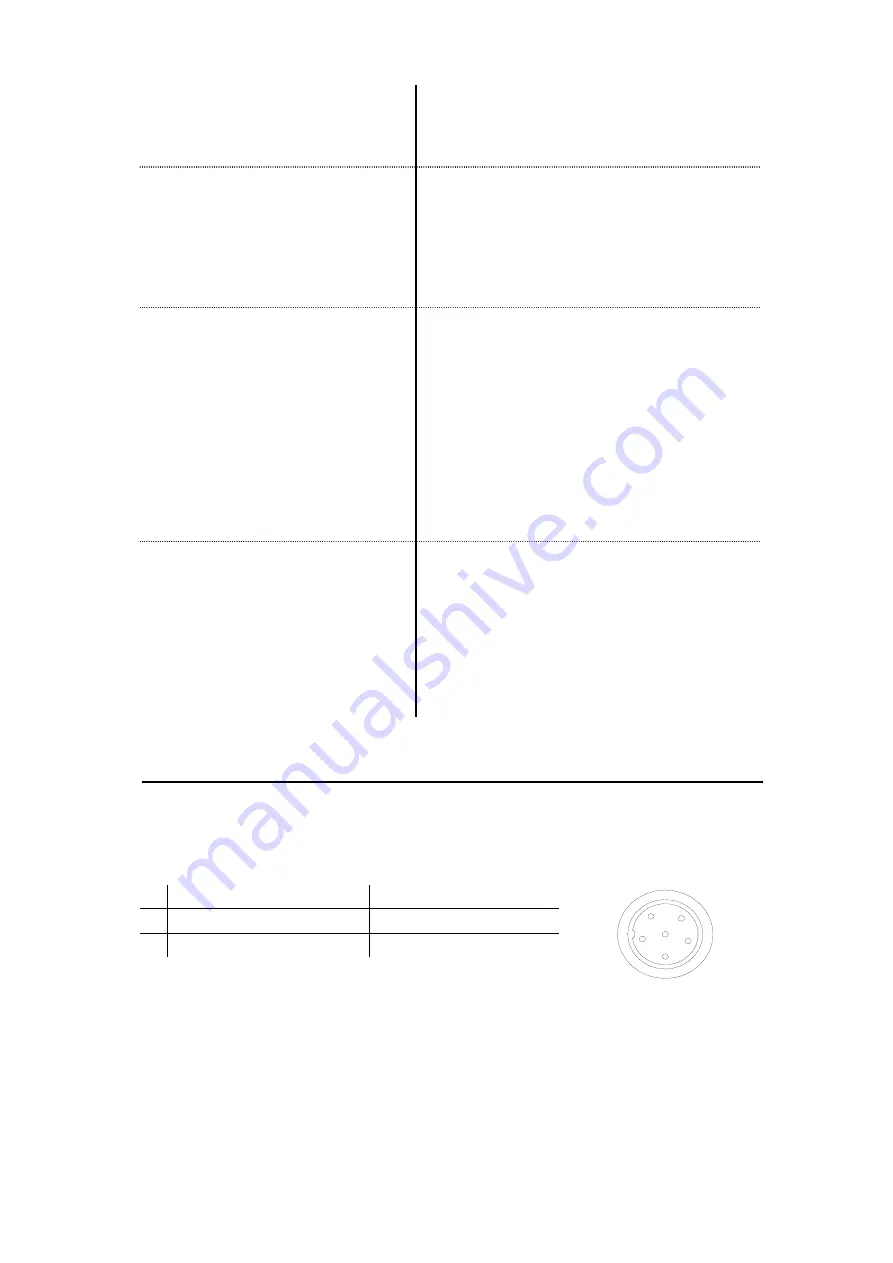

Disconnect the plug and measure the resistance value between the connecting plug pins as follows.

If the value of ‘a’ and ‘b’ are outside the below value, replace the heating element (sensor) .

Refer to procedures 1 and 2. If the value of ‘c’ is over the below value, remove the oxidization

film by lightly rubbing with sand-paper or steel wool the points as shown.

1

6

3

5

4

2

a.

Between pins 4 &5 (Heating Element)

Under 4

Ω

(Normal)

b. Between pins 1 &2 (Sensor )

Under 10

Ω

(Normal)

c.

Between pins 3 & Tip

Under 2

Ω