TM

Model 3700

M0275-01

1/16

6-5

Troubleshooting

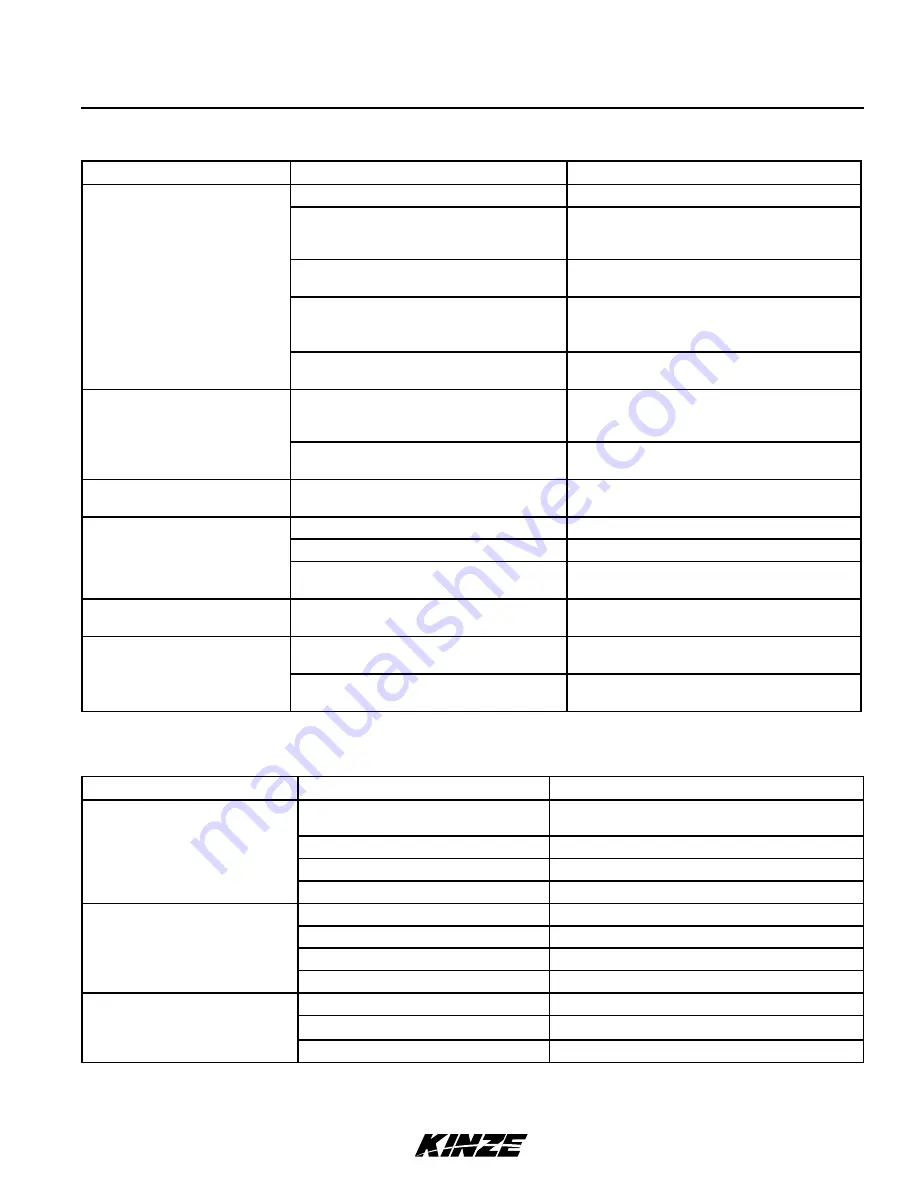

SEED METER (BRUSH-TYPE)

PROBLEM

POSSIBLE CAUSE

SOLUTION

Low count.

Meter RPM too high.

Reduce planting speed.

Seed sensor not picking up all seeds

dropped.

Clean seed tube. Switch meter to different

row. If problem stays in same row, replace

sensor.

Lack of lubrication causing seeds not to

release from disc properly.

Use graphite or talc as recommended.

Seed size too large for seed disc being

used.

Switch to smaller seed or appropriate seed

disc. See “Brush-Type Seed Meter” for

proper seed disc for size of seed being used.

Seed treatment buildup in meter.

Reduce treatment amount used. Thoroughly

mix treatment with seed. Add talc.

Low count at low RPM and

higher count at higher RPM.

Foreign material lodged in upper brush.

Remove seed disc and remove

foreign material from between brush retainer

and bristles. Clean thoroughly.

Worn upper brush.

Replace. See “Brush-Type Seed Meter

Maintenance”.

Low count at higher RPM and

normal count at low RPM.

Seed disc worn in agitation groove area.

Replace disc. Replace. See “Brush-Type

Seed Meter Maintenance”.

High count.

Seed size too small for seed disc.

Switch to larger or appropriate seed disc.

Incorrect seed rate transmission setting.

Reset transmission. Refer to rate charts.

Upper brush too wide (fanned out) for

small seed size.

Replace upper brush.

High count. (Milo/Grain

Sorghum)

Incorrect brush retainer being used.

Make sure GD8237 brush retainer is used to

keep upper brush from fanning out.

Upper brush laid back.

Seed treatment buildup on brush.

Remove brush. Wash with soap and water.

Dry thoroughly before reinstalling.

Foreign material buildup at base of brush. Remove brush retainer and brush. Clean

thoroughly. Reinstall.

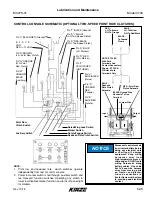

SOLENOID VALVE

PROBLEM

POSSIBLE CAUSE

SOLUTION

No solenoids operate.

Low voltage.

Must be connected to 12 volt DC only.

Negative ground.

Blown fuse.

Replace control console fuse with AGC-15 amp.

Battery connection.

Clean and tighten.

Wiring harness damaged.

Repair or replace.

One solenoid valve will not

operate.

Bad switch.

Replace on control panel.

Cut wire in harness.

Locate and repair.

Bad coil.

Replace.

Poor connection at coil.

Check.

Valve operating when not

energized.

Valve stem stuck open.

Replace cartridge.

O-ring leaking.

Install new O-ring kit.

Foreign material under poppet.

Remove and clean cartridge.

Summary of Contents for 3700

Page 2: ......

Page 3: ......

Page 4: ......

Page 18: ...This page intentionally left blank ...

Page 54: ...This page intentionally left blank ...

Page 102: ...This page intentionally left blank ...

Page 119: ...This page intentionally left blank ...