TM

Model 3700

M0275-01

Rev. 10/18

5-19

Lubrication and Maintenance

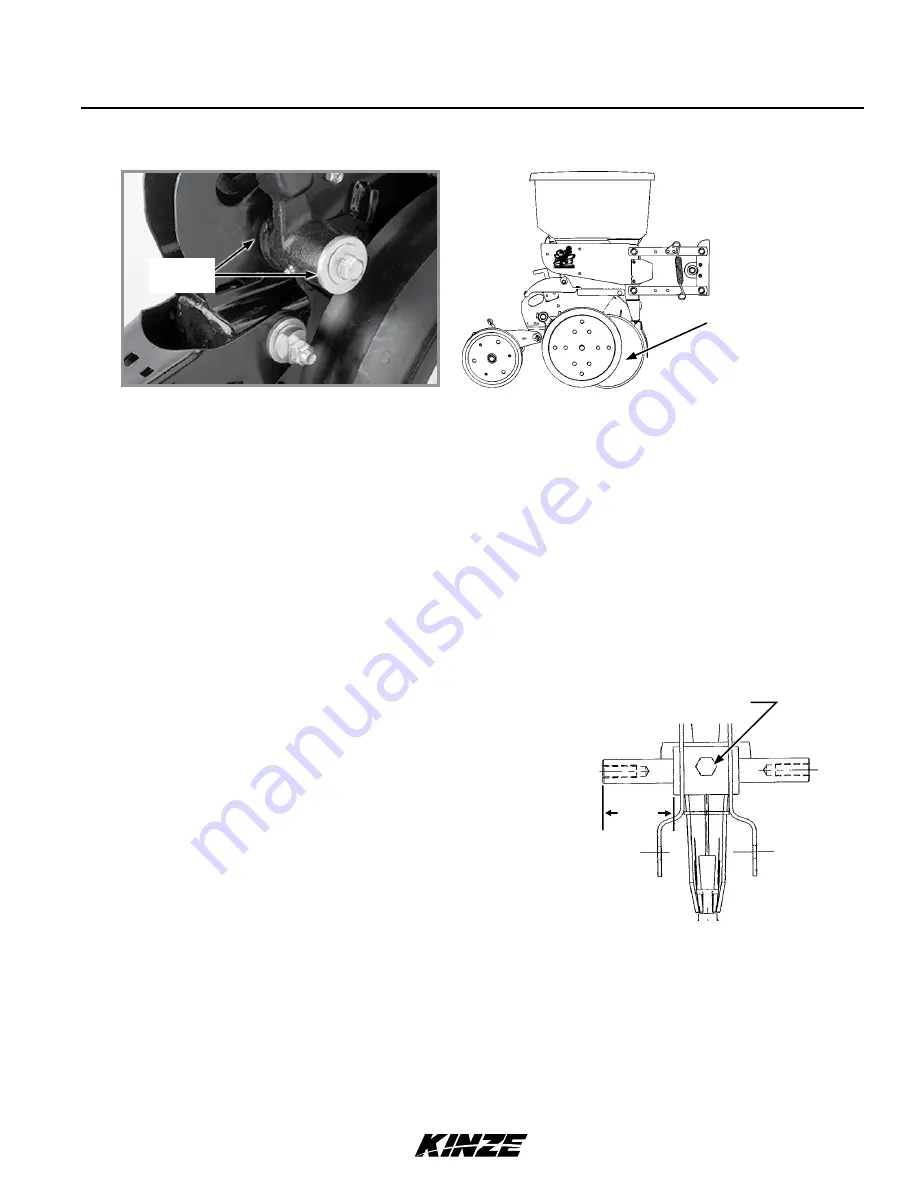

Gauge wheels should lightly contact opener blades to prevent accumulation of dirt or trash. Gauge wheels and opener

blades should turn with only slight resistance.

Add or remove machine bushings between shank and gauge wheel arm to adjust clearance between gauge wheels

and opener blades. Store remaining machine bushings between gauge wheel arm and flat washer on outer side of

gauge wheel arm.

NOTE: It may be desirable to space gauge wheel further from blade when operating in sticky soils.

Shim gauge wheel

to lightly contact

opener disc blade.

Check adjustment

in field position.

GAUGE WHEEL ADJUSTMENT

Gauge wheel adjustment

Machine

bushings

1. Remove gauge wheel and arm assemblies from shank

assembly.

2. Remove

½

" x

¾

" cap screw that locks pivot spindle in

place and remove spindle.

3. Install replacement spindle and position as shown. Exact

centering is critical.

4. Install

½

" x

¾

" cap screw and torque to lock pivot spindle

in place.

5. Install gauge wheel and arm assemblies. Shim for proper

gauge wheel tire/disc blade clearance.

GAUGE WHEEL ARM PIVOT SPINDLE REPLACEMENT

73 mm

Pivot spindle cap screw

Summary of Contents for 3700

Page 2: ......

Page 3: ......

Page 4: ......

Page 18: ...This page intentionally left blank ...

Page 54: ...This page intentionally left blank ...

Page 102: ...This page intentionally left blank ...

Page 119: ...This page intentionally left blank ...