M0275-01

Model 3700

5-36

Rev. 10/18

TM

Lubrication and Maintenance

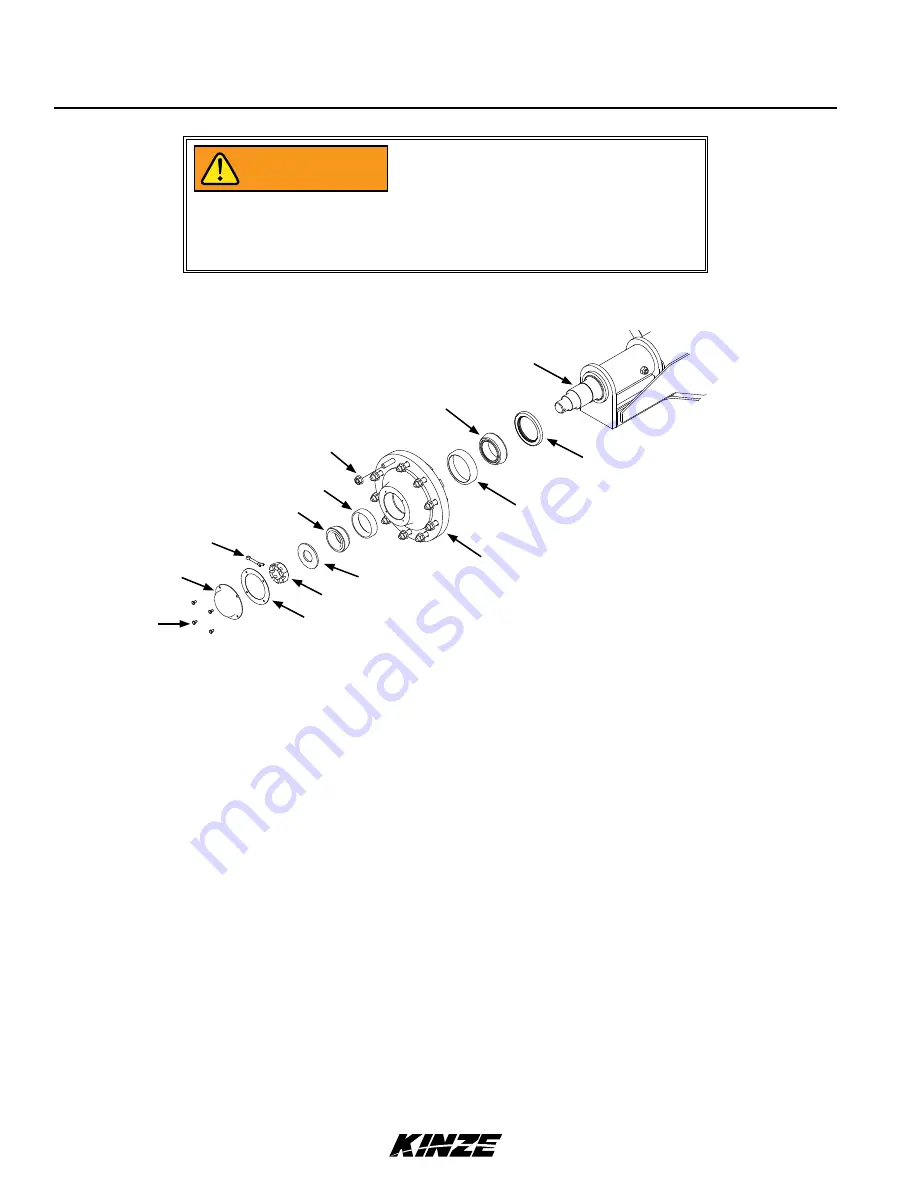

1. Raise tires clear of ground and support with jack stand. Remove wheels.

2. Remove dust cap attachment hardware and cap from wheel hub.

3. Remove cotter pin, slotted nut, and 2" washer.

4. Slide hub from axle spindle. Use a hub puller if necessary.

5. Remove bearings and cups from hub and discard. Thoroughly clean and dry wheel hub.

6. Press in new bearing cups with thickest edges facing in.

7. Pack bearing with heavy-duty wheel bearing grease. Thoroughly force grease between roller cone and bearing

cage. Fill space between bearing cups and hub with grease.

8. Place inner bearing in hub and press in new grease seal with lip pointing towards bearing.

9. Clean axle spindle and install hub.

10. Install outer bearing, 2" washer, and slotted nut. Tighten slotted nut while rotating hub until there is some drag. This

ensures all bearing surfaces are in contact. Back off slotted nut to nearest locking slot and install cotter pin. Check

bearing endplay.

11. Fill dust cap half full of wheel bearing grease and install on hub with four hex head cap screws.

12. Install wheels and remove jack stand. Torque

¾

" flange nuts to 380 Nm.

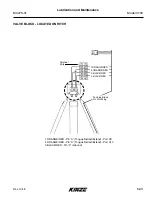

TRANSPORT WHEEL BEARING REPLACEMENT

2" washer

Hub

¾

"-16 flange nut

Inner bearing

Spindle

Dust cap

Outer bearing

Bearing cup

Seal

Cotter pin

2" slotted nut

Hex head

cap screw

Bearing cup

Seal

Uncontrolled machine movement can

crush or cause loss of control resulting

in death, serious injury, or damage to

property and equipment. Install all safety

lockup devices before working under or

transporting this equipment.

WARNING

Summary of Contents for 3700

Page 2: ......

Page 3: ......

Page 4: ......

Page 18: ...This page intentionally left blank ...

Page 54: ...This page intentionally left blank ...

Page 102: ...This page intentionally left blank ...

Page 119: ...This page intentionally left blank ...