TM

Model 3700

M0275-01

Rev. 10/18

5-37

Lubrication and Maintenance

TM

Entrance of air into pump will cause

rapid and severe corrosion. KEEP AIR

OUT OF PUMP!

NOTICE

NOTE: SUSPENSION FERTILIZER must be flushed from pump for ANY storage period.

1. Flush pump with 19 to 38 liters of fresh water and circulate until all corrosive salts are dissolved in pump.

2. Set pump on 10. Draw in a mixture of half diesel fuel and 10 weight oil until discharge is clean. Plug inlet and outlet.

PISTON PUMP STORAGE

LOW-RATE LIQUID FERTILIZER SYSTEM

Clean strainers daily.

Flush all lines with water for 30 to 60 seconds then drain water before storage.

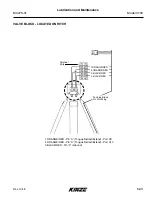

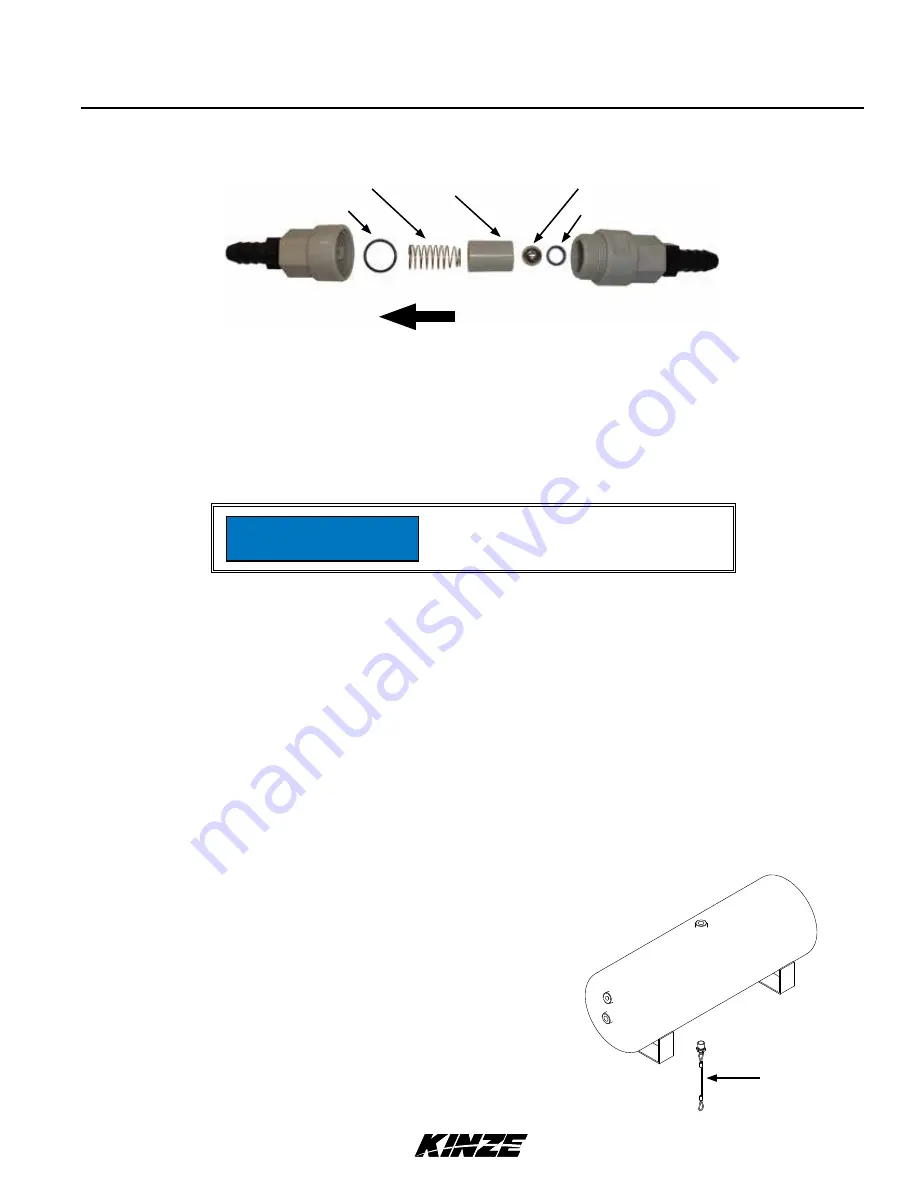

FERTILIZER CHECK VALVE CLEANING AND REPAIR

1. Unscrew valve body and separate halves. Note direction and location of parts.

2. Clean and inspect parts. Flush with clean water. Replace damaged parts.

3. Reassemble exactly as shown. O-ring and valve seat must be firmly in place inside each half of valve body.

Direction of flow

Valve seat

Valve ball

Guide

O-ring

Spring

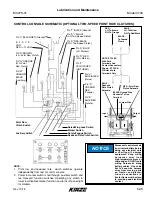

Moisture should be drained daily from the tank. Tank should be

drained completely for storage.

To drain tank, locate drain plug on the bottom of tank. Stand off

to the side of tank and pull cable attached to drain.

NOTE: If mositure is not drained from tank rust particles will

form inside tank.

PNEUMATIC DOWN PRESSURE AIR COMPRESSOR TANK

Pull drain

plug

Summary of Contents for 3700

Page 2: ......

Page 3: ......

Page 4: ......

Page 18: ...This page intentionally left blank ...

Page 54: ...This page intentionally left blank ...

Page 102: ...This page intentionally left blank ...

Page 119: ...This page intentionally left blank ...