M0275-01

Model 3700

6-4

1/16

TM

Troubleshooting

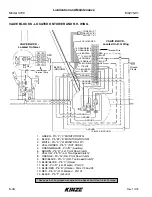

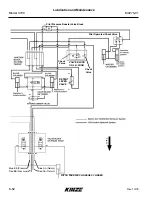

PTO PUMP DRIVE AND OIL COOLER OPTION

PROBLEM

POSSIBLE CAUSE

SOLUTION

Pump is squealing.

Lack of oil to pump.

Check for plugged suction strainer.

Check oil level.

Oil temperature high.

Low oil level.

Check oil level and add as required.

Desired fan speed cannot be

achieved.

Low oil level.

Check oil level and add as required.

Plugged filter.

Check and change as required.

Vacuum level not displayed.

Digital vacuum gauge console power

OFF.

Turn ON.

Cable not plugged in.

Check connection.

Digital vacuum gauge console

has no power.

Check fuse.

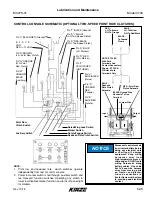

ROW MARKER OPERATION

PROBLEM

POSSIBLE CAUSE

SOLUTION

Right marker lowering slower

than left marker.

Solenoid valve cartridge in port V1 not

opening completely.

Switch with cartridge in port V2. If problem

repeats, replace cartridge.

Hose pinched or collapsed.

Inspect hose routing. Replace or repair

hoses as required.

Left marker lowering slower

than right marker.

Solenoid valve cartridge in port V2 not

opening completely.

Switch with cartridge in port V1. If problem

repeats, replace cartridge.

Hose pinched or collapsed.

Inspect hose routing. Replace or repair

hoses as required.

Both markers lowering.

Solenoid valve cartridge stuck open. If left

marker switch is selected, right cartridge

(V1) is defective. If right marker switch is

selected, left cartridge (V2) is defective.

Replace solenoid valve cartridge.

Neither marker lowers.

Blown fuse.

Check red light on control console. It

should be on if switch is on. If light is not

on, switch to opposite marker position. If

light comes on, switch may be defective.

Replace switch. Otherwise replace fuse.

Coils at V1 and V2 not energized.

Poor ground on wire, bad wire connection

or damaged wire. Repair as required.

Marker flow control valve closed too far.

See “Row Marker Speed Adjustment”.

Neither marker will raise.

Marker flow control valve closed too far.

See “Row Marker Speed Adjustment”.

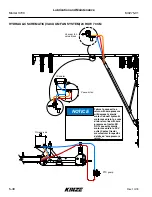

Right marker will not lower.

Solenoid coil in port V1 not energized.

Check switch on control console. Replace

if defective. Check coil ground wire. Check

for poor connection or damaged wire.

Solenoid cartridge in port V1 stuck closed.

Switch cartridge with one on the planter

you know is operating properly. If right

marker lowers, replace defective cartridge.

Left marker will not lower.

Solenoid coil in port V2 not energized.

Check switch on control console. Replace

if defective. Check coil ground wire. Check

for poor connection or damaged wire.

Solenoid cartridge in port V2 stuck closed.

Switch cartridge with one on the planter

you know is operating properly. If left

marker lowers, replace defective cartridge.

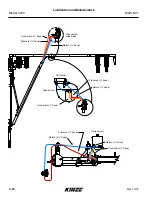

Markers traveling too fast

and damaging rubber stop

on transport stands and/or

damaging pivot at rod end of

marker cylinders.

Marker transport stand not adjusted

correctly to allow marker cushion cylinders

to operate as designed.

See “Row Marker Transport Stand

Adjustment”.

Adjust row marker flow control valve.

See “Row Marker Speed Adjustment”.

Summary of Contents for 3700

Page 2: ......

Page 3: ......

Page 4: ......

Page 18: ...This page intentionally left blank ...

Page 54: ...This page intentionally left blank ...

Page 102: ...This page intentionally left blank ...

Page 119: ...This page intentionally left blank ...