10-16 DK55

069OA23A

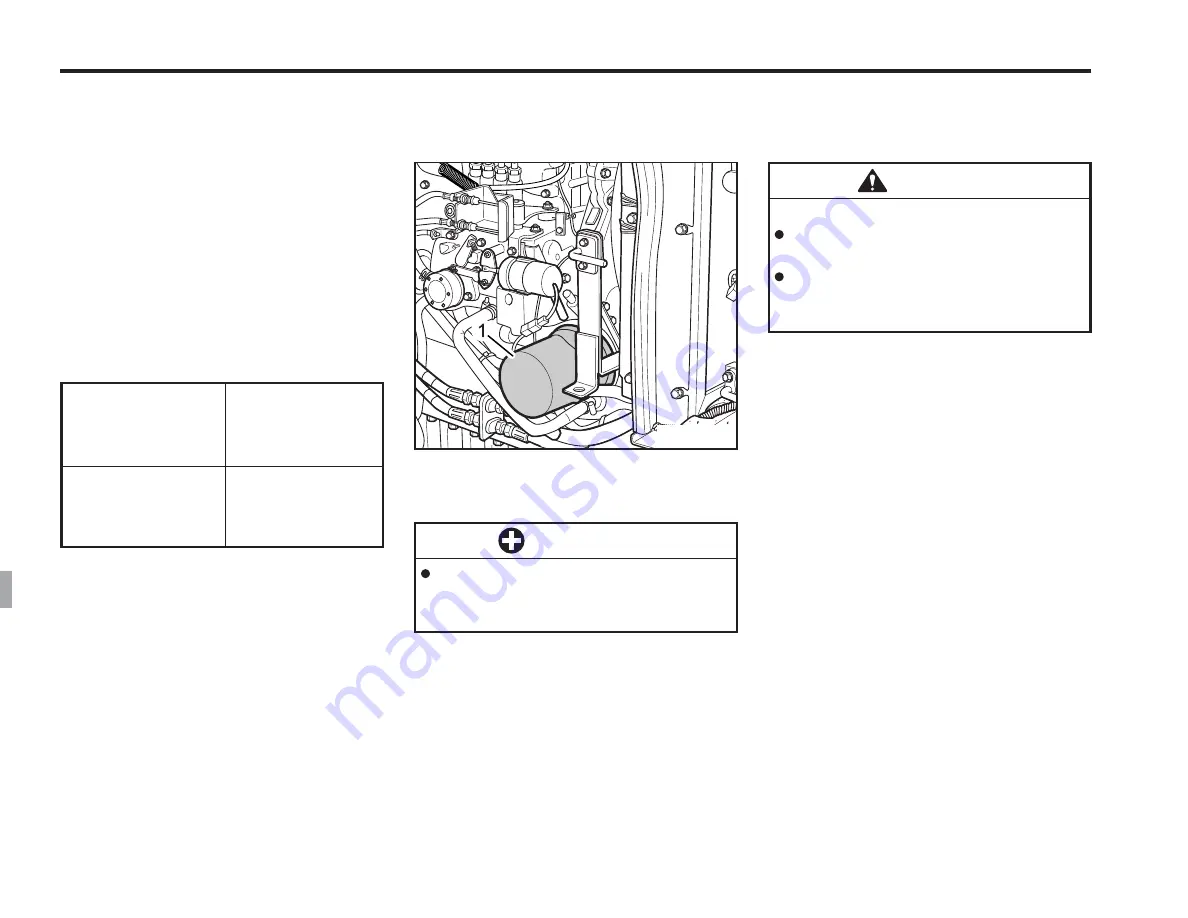

(1) Oil Filter Cartridge

EVERY 200 HOURS

REPLACING ENGINE OIL FILTER

1. Remove the oil filter.

2. Put a film of clean engine oil on the

rubber seal of the new filter.

3. Tighten the filter quickly until it con-

tacts the mounting surface.

Tighten filter by hand an additional half

turn only.

4. After the new filter has been replaced,

the engine oil normally decreases a

little. Make sure that the engine oil does

not leak through the seal and be sure

to check the oil level on the dipstick.

Then, replenish the engine oil up to

the prescribed level.

CAUTION

To avoid personal injury:

Be sure to stop the engine be-

fore changing oil filter cartridge.

Allow engine to cool down

sufficiently, oil can be hot and can

burn.

IMPORTANT

To prevent serious damage to the

engine, use only a KIOTI genuine

filter.

6. Check temperature of electrolyte, if it

r e a c h e s 4 0 ° C ( 1 0 5 ° F ) , l o w e r t h e

charging rate. When temperature is too

high, reduce charging rate and charge

for a proportionately longer period.

7. If the tractor is stored after original

c h a r g e , p e r i o d i c a l l y r e c h a r g e a s

shown below :

A battery is fully charged when the

cells are all gassing freely and the

specific gravity ceases to rise for

three consecutive readings taken at

hour intervals. Specific gravity shall

then be adjusted to showed in Table

1.

8. Check electrolyte level two hours af-

ter chargingis finished and correct it.

< Table 3 >

about 5 hours

10

30

Period of storage

from manufacture

(months)

Fresh charging

(times)

0 ~ 6

6 ~ 12

over 12

Summary of Contents for DK55

Page 6: ......

Page 8: ......

Page 21: ...SAFETY PRECAUTIONS 1 13 CAUTION LABELS 069O130A ROPS...

Page 22: ...1 14 DK55 069O131A CABIN...

Page 25: ...SAFETY PRECAUTIONS 1 17 15 T4817 52201 14 T2625 55111...

Page 26: ...2SERVICING OF TRACTOR...

Page 28: ...3SPECIFICATIONS...

Page 32: ...SWITCHES CONTROLS HYDRAULIC UNIT ASSURE SAFE OPERATION 4INSTRUMENT PANEL AND CONTROLS...

Page 49: ...5OPERATING PRE OPERATION OPERATING NEW TRACTOR OPERATING THE ENGINE OPERATING THE TRACTOR...

Page 65: ...3 POINT HITCH DRAWBAR 6THREE POINT HITCH DRAWBAR...

Page 68: ......

Page 69: ...3 POINT HITCH CONTROL SYSTEM AUXILIARY HYDRAULICS 7HYDRAULIC UNIT...

Page 75: ...TIRES TREAD BALLAST 8WHEELS TIRES AND TREAD...

Page 80: ......

Page 81: ...SERVICE INTERVALS LUBRICANTS 9MAINTENANCE...

Page 84: ......

Page 112: ......

Page 113: ...TRACTOR STORAGE REMOVING THE TRACTOR FROM STORAGE 11STORAGE...

Page 116: ......

Page 117: ...ENGINE TROUBLESHOOTING TRACTOR TROUBLESHOOTING BATTERY TROUBLESHOOTING 12TROUBLESHOOTING...

Page 131: ...14INDEX...

Page 135: ...SERVICE RECORD DATE CODE NO DESCRIPTION REMARKS Ref No Hour Meter...