5 Maintenance

5.6 Check and maintenance every 200hours

Carry out the following inspection and

maintenance every 50h.

■

Check and adjusting of tension of fan belt

1. Press the central part of driving belt wheel of

fan and DC generator belt wheel with force of

10kgf and measure the deflection A.

2. If the deflection exceeds standard value,

loosen 2 bolts on DC generator. Move the DC

generator and adjust tension of its belt.

Deflection of fan belt wheel A……Standard

value

:

appro.7

~

9mm/58.8

~

68.6N

(

6

~

7kgf

)

3. Check each belt wheel, type V slot and type V

belt for any damages; particularly check type V

belt to see if it contacts with bottom of type V slot.

4. Belts become long loosing adjustment function

or have any cut wound or cracks; in case of any,

please replace in time.

Important

* In case of working under weak tension of belt

and continuous operating of the machine, the belt

may slip to cause performance reduction of the

engine and shorten its service life. Therefore,

check and adjust belt tension.

* Stop the engine if charging lamp illuminates just

caused by broken belt.

■

Check radiator pipe

1. Tighten loosened ring clamp; in case of water

leakage, tighten the ring clamp.

2. Replace the pipe in case of expansion,

stiffening or cracks, and tighten the ring clamp.

Ring clamp

Rubber pipe on radiator

■

Cleaning and check off air filter element

Open engine cover, remove dust shield and take

out the element. Clean the element and dust

shield as well as internal surface of casing.

Dust shield

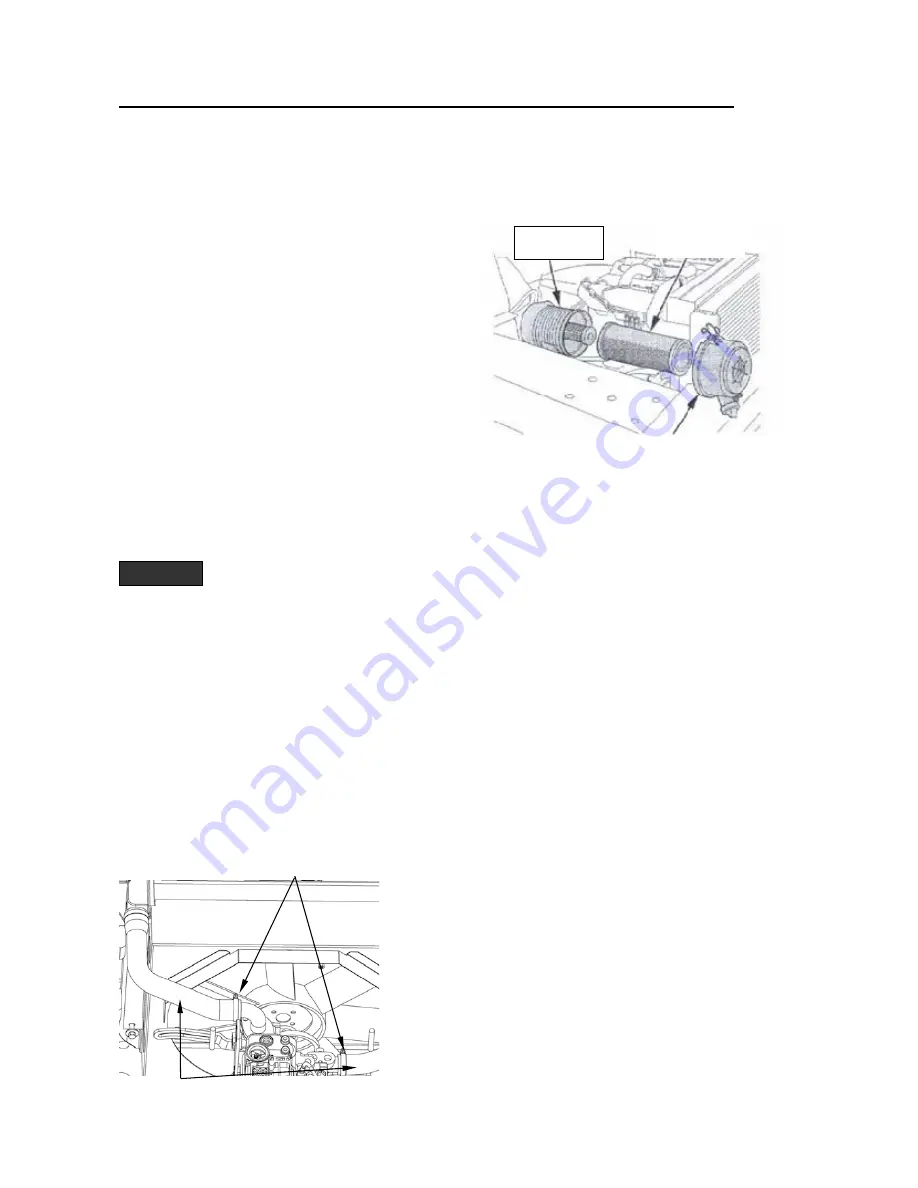

◆

Cleaning method

Blow and clean exterior of element with dry

compressed air [below 203kPa

(

2.1kgf/cm

2

)

];

blow from interior to exterior to clean all dust and

dirt. Wear protection glasses to prevent dust

entering your eyes, especially working in places

with many sands. Carry out cleaning and check

as early as possible.

5.7 Check and maintenance every 250 hours

Carry out the following inspection and

maintenance every 50h.

■

Check and tightening of nuts on tyre hubs

Refer to [Replacement of tyre] (page 35).

■

Replacement of engine oil

(

50h for initial time

)

1. Remove the drainage bolts on engine oil tray at

bottom of engine, put them on lower left of rear

support and drain out the engine oil.

2. Tighten each bolt after oil drainage.

3. Fill certain fresh engine oil through filling

opening.

4. Keep the engine racing first and check oil level

with oil gauge about 5 min after stopping racing.

Element

Casing

31

Summary of Contents for KDD03

Page 2: ......