IMPORTANT NOTICE:

DO NOT return to place of purchase!!!

Please contact Customer Service hotline at 800-913-8999 for help.

Page7

GAS REQUIREMENTS & LEAK TESTING

NEVER CONNECT AN UNREGULATED GAS SUPPLY TO THE HEATER

PRECAUTIONS

z

Periodically check the whole gas system for

leaks or immediately check if the smell of

gas is detected

z

Extinguish all open flames.

z

Never leak test while smoking.

z

If you cannot stop a leak, turn off the gas

supply and call the Customer Service hotline,

the dealer where you made the purchase or

your gas supplier.

z

The heater must be checked with a full

cylinder.

z

Do not use the heater until all connections

have been leak tested and do not leak.

z

Only those parts recommended by the

manufacturer should be used. Substitution

will void the warranty.

GAS REQUIRMENTS

z

Maximum inlet pressure to propane

regulator must not exceed 100 PSI.

z

A minimum supply pressure of 11.0 W.C. is

required for the purpose of input adjustment

for propane gas.

z

The pressure regulator and hose assembly

supplied with the appliance must be used.

Replacement pressure regulator and hose

must be specified by the appliance

manufacturer.

z

The installation must conform with local

codes or in the absence of local codes, with

National Fuel Gas Code, ANSI

Z223.1-1996.

z

The heater comes equipped with a hose

assembly for hook-up to a standard

z

A dented, rusted or damaged propane tank

may be hazardous and should be checked by your

tank supplier. Never use a propane tank with a

damaged valve connection.

z

The propane tank must be constructed and

marked in accordance with the specifications for

LP gas cylinders of the US Department Of

Transportation (DOT)

z

The propane tank must be arranged to provide

for vapor withdrawal from the operating

cylinder

z

Never connect an unregulated propane tank

to the heater

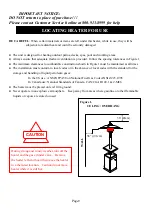

LEAK TESTING

z

Gas connections on the heater are leak tested at

the factory prior to shipment. A complete gas

tightness check must be performed at the

installation on site due to possible miss handing

in shipment or excessive pressure being applied

to the heater.

TO LEAK TEST

z

Make a soap solution of one part liquid detergent

and one part water. The solution can be applied

with a spray bottle brush or rag. Soap bubbles

will appear where a leak is present

z

Make certain the safety control valve is in the

‘OFF’ position

z

Turn the gas supply ‘ON’.

z

If a leak is present turn ‘OFF’ the gas supply,

tighten any leaking fitting, turn gas supply ‘ON’

gas tank. The propane tank is not included. and recheck.

propane