Summary of Contents for KMW Univator

Page 1: ...Operator and Service Manual Cum Spare Parts Catalogue Farm Mechanisation Business Unit...

Page 2: ......

Page 4: ......

Page 6: ......

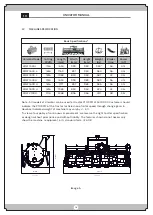

Page 9: ...UNIVATOR MANUAL 1 3 NOMENCLATURE 1 0 Univator Front Side Univator Rear Side 07...

Page 33: ...6 0 SPARE PARTS CATALOGUE GEAR BOX ASSEMBLY KMW H SERIES 31...

Page 41: ...6 0 SPARE PARTS CATALOGUE GEAR BOX ASSEMBLY KMW L SERIES 39...

Page 44: ...6 0 SPARE PARTS CATALOGUE 6 5 CARDAN SHAFT ASSEMBLY 42...

Page 46: ...6 0 SPARE PARTS CATALOGUE 6 6 COULTER WHEEL ASSEMBLY 44...

Page 53: ...10 0 NOTES 51...

Page 54: ...10 0 NOTES 52...

Page 55: ......