KisanKraft

®

Agricultural Portable Sprayer (Power)

KK-P767/ P768/ P769/ P780, KK-TPS-60T

Agricultural Knapsack Sprayer (Power)

KK-707/ 708/X/AL, KK-KPS-162 / 802

This warranty is null & void, if you fail to register the warranty with

KisanKraft by

sending the KisanKraft Copy with dealer’s stamp.

: www.kisankraft.com

: info@kisankraft.com

: +91.80. 6835 7800

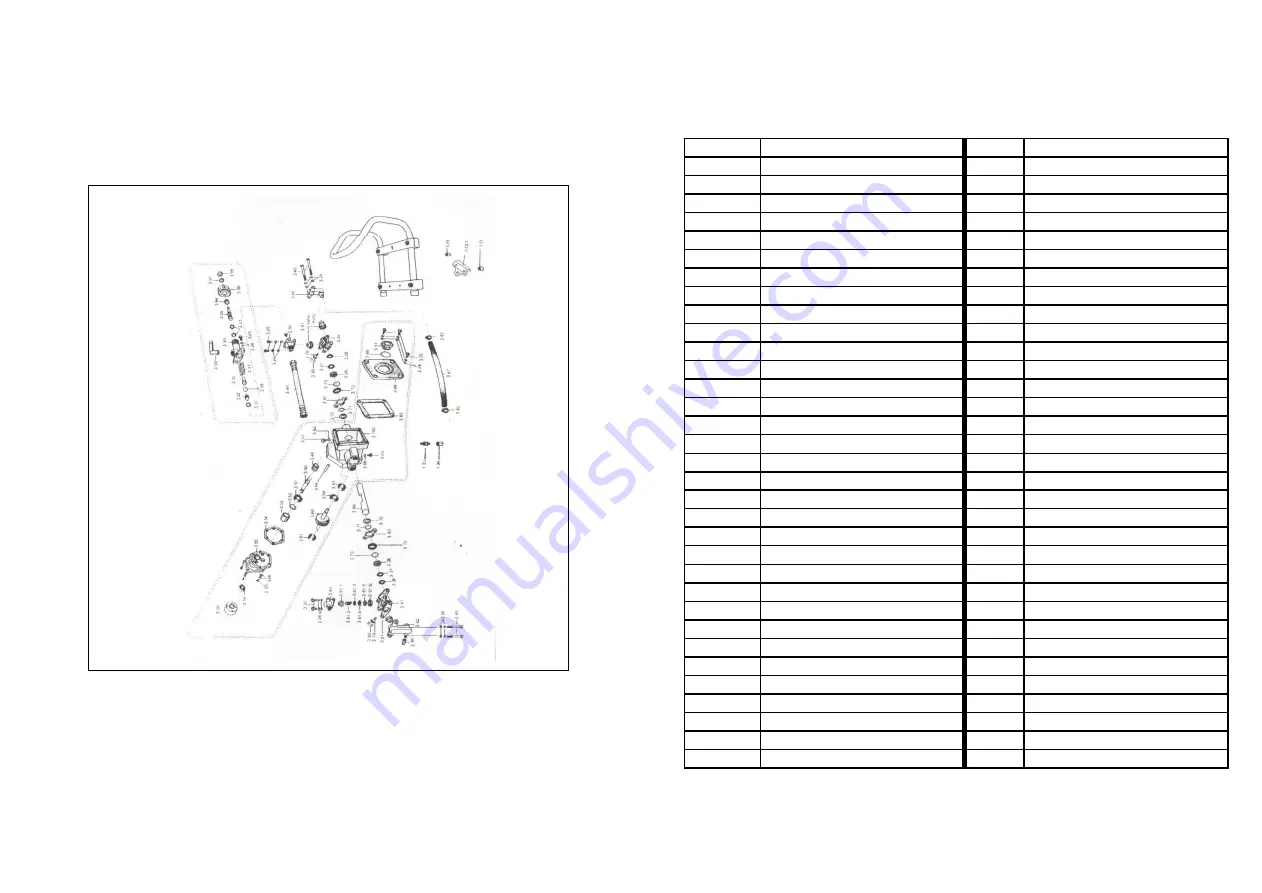

PRESSURE PUMP PARTS - DIAGRAM

(Portable Power Sprayer)

KisanKraft

®

2 - STROKE PETROL ENGINE

: www.kisankraft.com

: info@kisankraft.com

: +91.80. 6835 7800

Page 25 of 48

PRESSURE PUMP PARTS-LIST

Part no.

Part name (body)

Part no.

Part name (body)

1-11

Shake- proof plug 6 mm

3-57

Ball bearing 608

1-12-1

Fixing bracket

3-58

Ball bearing 6203

3-24

Washer

3-59

Oil seal for upper case

3-25

Hex bolt m6x16

3-60

Gear shaft

3-26

Grease ring

3-61

Ball bearing 608

3-27

V-packing

3-62

O-ring 12x1.8

3-28

Adjusting ring

3-63

Oil inlet bolt

3-29

Right pressure chamber

3-64

Gear box cover

3-30

Right delivery chamber

3-65

O-ring, gear box cover

3-31

O-ring 10x1.8

3-66

O-ring, oil window 31x 3

3-32

Valve seat

3-67

Oil window

1-33

Shake- proof plug 6 mm

3-68

O-ring 6.3x1.8

1-34

Pump bracket

3-69

Oil outlet bolt

3-35

Ball valve

3-70

Oil seal for piston

3-36

Spring seat

3-71

O-ring for piston 17x1.8

3-37

Spring

3-72

Packing seat

3-38

Overflow joint

3-73

O-ring 18x2.65

3-39

Pressure regulating valve body

3-79

Grease cup

3-40

Right suction chamber

3-80

Cap for grease cup

3-41

Left pressure chamber

3-81

Valve assembly

3-42

Left suction chamber

3-81-1

Valve cage

3-43

Left delivery chamber

3-81-2

Valve spring

3-44

Suction joint

3-81-3

Valve plug

3-45

Hex bolt m6x73

3-81-4

Valve seat

3-46

Pump delivery hose assembly

3-81-5

Valve ring

3-47

Pump suction hose

3-81-6

Valve packaging

3-48

Roller bearing

3-82

Hose clamp

3-49

Pin

3-38

Metal plate washer

3-50

Pinion shaft

3-94

Cap nut

3-51

Ball bearing 6201

3-95

Regulating screw

3-52

O-ring 12x1.8

3-96

Adjusting pan

3-53

Bush

3-97

Washer

3-54

Gasket, upper case

3-98

Nut