KisanKraft

®

AGRICULTURAL INTER-CULTIVATOR

KK-IC-300D / 307D / 350D / 357D

KK-CRT-550D

: +91.80. 6835 7800

Page 15 of 80

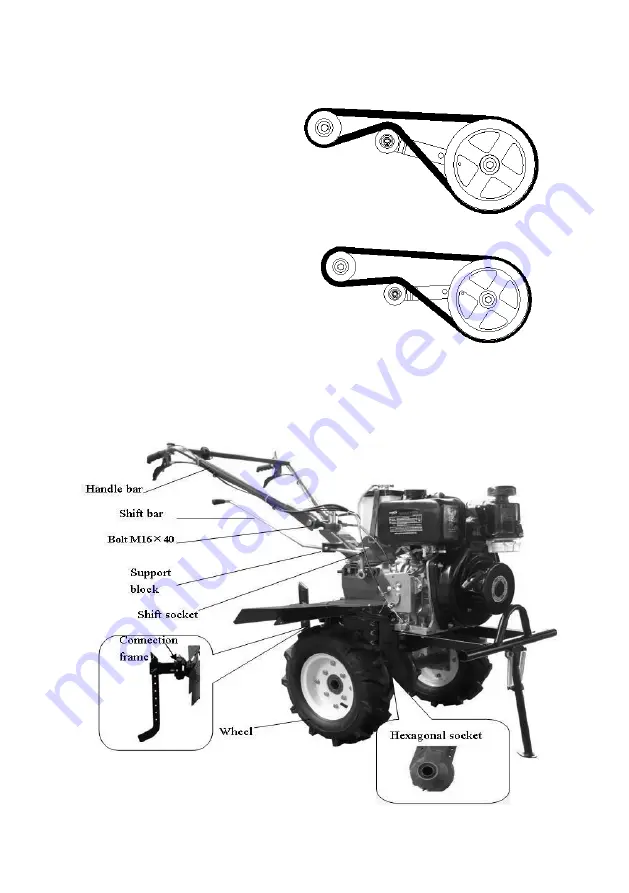

3.1

Normal range of belt tension

degree is 25mm or so, when we

loosen brake handle, tension pulley

moves upward to press tightly belt

and transmission begins to work,

when we clench clutch handle,

tension pulley moves down to make

belt loosen, engine stops to input

transmission to gear box.

Loosing condition of clutch handlebar

3.2

If belt tension degree is not in

the normal range, it

’s necessary to

adjust. To loosen the four fixed

bolts of the engine, if the belt is too

loose, we make the engine move

forward, if the belt is too tight, we

make the engine move backward,

until tension level is in the normal

range. Tighten the four fixed bolts of

the engine.

Clenching condition of clutch handlebar

Assembly

–IC-300D / 307D