KisanKraft

®

Agricultural Inter-Cultivator

KK-IC-210P

This warranty is null & void, if you fail to register the warranty with KisanKraft

by sending the KisanKraft Copy with dealer’s stamp. KisanKraft Limited

: +91.80. 6835 7800

Page 46 of 64

1.

Air cleaner

: A dirty air cleaner will restrict air flow into the carburetor. To prevent carbure-

tor malfunction, service the air cleaner regularly. Service more frequently when operating

the generator in extremely dusty areas.

•

Check air cleaner core, get rid of fouling, and keep the core clean.

•

Check bolts, fasten the loose ones.

•

Check whether lubricant oil level is within the limits.

2.

Clean the core after 25hrs of engine run

3.

Clean carbon fouling of the spark plug after working up to 50hrs. Check the clearance,

and adjust the gap to 0.6-0.7mm (see figure 4-1). Check radiator, and clean fouling

among radiators.

•

Drain the oil while the engine is warm to assure rapid and complete draining.

•

Remove the drain plug and sealing washer, remove the oil filler cap, and drain the

oil.

•

Reinstall the drain plug and sealing washer. Tighten the plug securely.

•

Refill with the recommended oil and check the oil level.

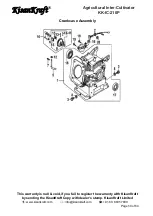

(1) Dismantle Spark Plug

(2) Adjust Clearance

4.

Clean the fuel tank and filter when working time reaches 100hrs: Remove the fuel cover,

drop out filter, and wash it with brush slightly. Remove fuel tank, clean the fouling and wa-

ter inside fuel tank. Reinstall fuel tank, place filter from fill-in hole, filling the clean fuel to

red line level.

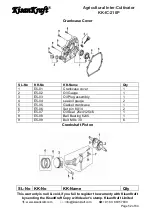

1) Drain plug

2) Engine

switch

3) Lower level

Check aging of fuel pipe every 2 years. If ageing, hardening and cracking is detected, have it

replaced. Tighten the joints, and check leakage.

Before storing the unit for an extended period: