Piezoelectric Pressure Sensor Type 601C/603C

Page

16

60xC_002-741e-08.18

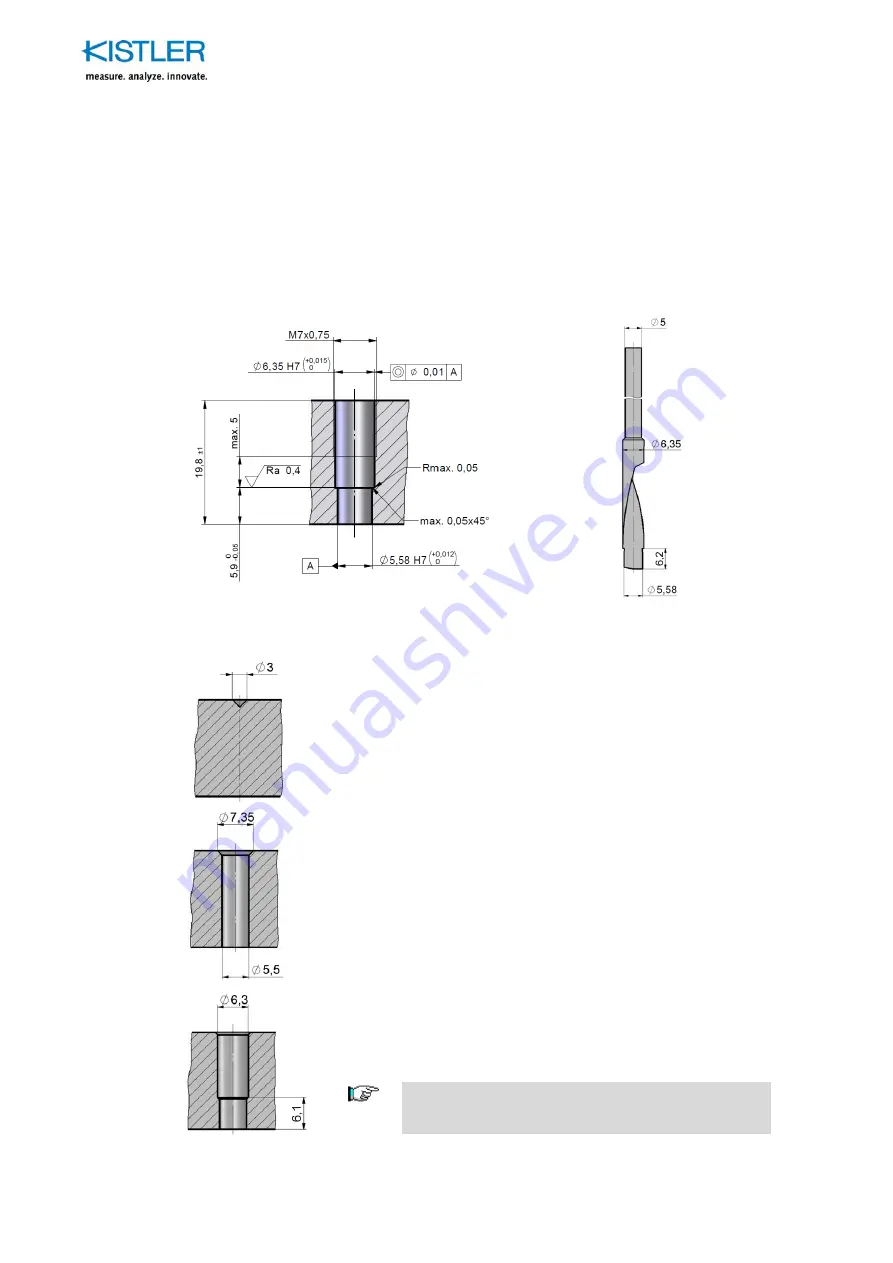

4.3 Manufacturing of mounting hole

4.3.1 Direct mounting (ISO)

The following procedure is recommended for the manu-

facturing of the direct mounting bore with Kistler step drill

type 1331 and for use with ISO floating clamp nut

6423B00 with a M7x0.75 thread.

Fig. 7: Flush mounting bore

Fig. 8: Kistler step drill, Type 1331

1. Centering hole, use a center drill with 3.0 mm diameter

and 90° chamfer angle.

2. Ø5.5 mm through-hole, use a spiral drill with 5.5 mm

diameter.

Ø7.35 mm countersink at the entrance of the Ø5.5 mm

blind hole, use a countersink cutter with a 90° chamfer

angle.

3. Ø6.3 mm blind hole, use a spiral drill with 6.3 mm

diameter. Select the bore depth accordingly, so that

the front cutting lips of the spiral drill do not undercut

the residual wall thickness of 6.1 mm at the diameter

of 5.5 mm.

A too deep blind hole will damage the contact surface

to the sensor (shoulder) and thus the sealing surface.

This could result in leakage at low pressure.