9

10

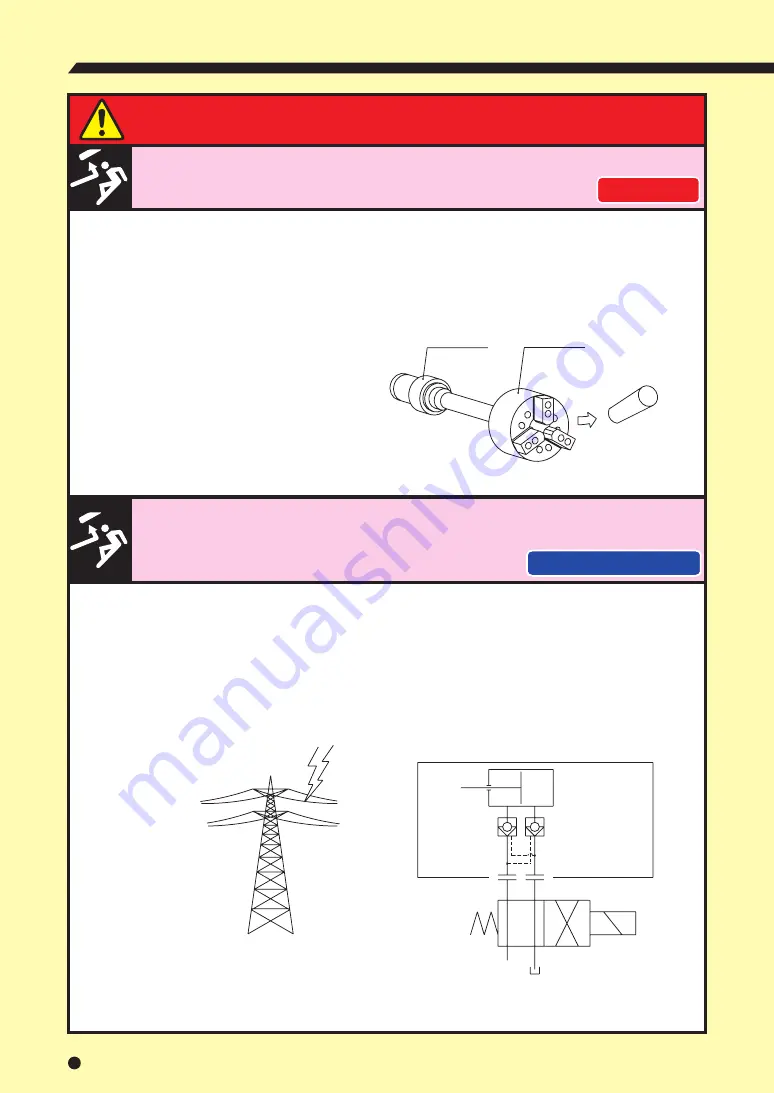

Use of a chuck and cylinder that cannot be used together safely may cause

the cylinder to break at high pressure resulting in the chuck

and work flying out.

For All Users

・Check that the chuck and the cylinder are in the safe combination when using at high pressure

with our company or the distributor. Especially when the cylinder of our company and a high

pressure chuck of other company are combined, confirmation is necessary.

・If one of the abnormal events shown below occurs during operation, immediately stop the machine

and consult with our company or the distributor.

・The work slips.

・Loss of accuracy.

・The work begins to chatter.

・The machine's vibration significantly

increases.

・The gripping force does not rise even

if hydraulic pressure is raised.

・If the hydraulic pressure suddenly drops due to blackout or malfunction of the hydraulic pump, etc.,

this is dangerous as work will fly out.

・Lock valve retains the hydraulic pressure inside the cylinder temporarily, when the hydraulic

pressure suddenly drops due to blackout or malfunction of the hydraulic pump, etc.

Use a cylinder with a lock valve (safety valve, check valve) incorporated in case of sudden

hydraulic pressure drop due to blackout, malfunction of the hydraulic pump, etc. Further,

use a solenoid valve with a circuit that retains the gripping

position when no current is carried.

10

Provide sufficient strength for the draw pipe (Refer to pages 23-24).

Provide sufficient screw depth for the draw pipe.

Firmly tighten the draw pipe.

Apply adhesive to the thread part of the draw pipe

and screw it in at the specified torque.

・If the draw pipe break, the gripping force

is instantly lost and this is dangerous as

work will fly out.

・If the screw depth of the draw pipe is

insufficient, the screw will break and the

gripping force will be lost instantly, and

this is dangerous as work will fly out.

・If the draw pipe is unbalanced, excessive

vibration could occur breaking the screw

and resulting in the gripping force being

lost and the work flying out.

・When screwing the draw pipe, piston to

the end of the pressing side stroke.

・If the engagement of the screw of the

draw pipe is loose, vibration may occur

resulting in breakage of the screw. If the

screw breaks, the gripping force will be

lost instantly, which is dangerous as the

work will fly out.

・When the screw is loosened, the jaw

stroke of the chuck becomes shorter and

this is very dangerous as the work will fly

out.

Do not modify the cylinder.

For All Users

・Doing so may damage the cylinder and cause oil leakage which could result in a fire.

And if the hydraulic oil leaks, the gripping force of the chuck will lower and the work may fly out,

which is dangerous.

・Do not attach additional machining such as screws.

・Do not detach parts of the cylinder from the cylinder.

Do not rotate the cylinder without hydraulic pressure.

For All Users

・Doing so could cause seizing inside the cylinder, leading to a drop in the gripping force of the chuck.

This is dangerous as work will fly out.

Important Safety Precautions

Failure to follow the safety precautions below will result in

serious injury or death.

DANGER

Failure to follow the safety precautions below will result in

serious injury or death.

DANGER

For Machine Tool Manufactures

For Machine Tool Manufactures

Failure to follow the safety precautions below could result in

serious injury or death.

WARNING

Type

Tightening torque

S1036

S1246・S1246L

S1552・S1552L

100 N・m

150 N・m

280 N・m

Type

Tightening torque

S1875・S1875L

S2091・S2091L

S2816

340 N・m

380 N・m

800 N・m

Chuck

Cylinder

FLY OUT

P

Piston

WORK

Cylinder

Back plate

Chuck

Draw pipe

Cylinder adapter

Solenoid valve

The grlipping position must be retained.

Loosening

Lightning

=Blackout

Lock valve

Cylinder

Gripping

Summary of Contents for S1036

Page 31: ......