22

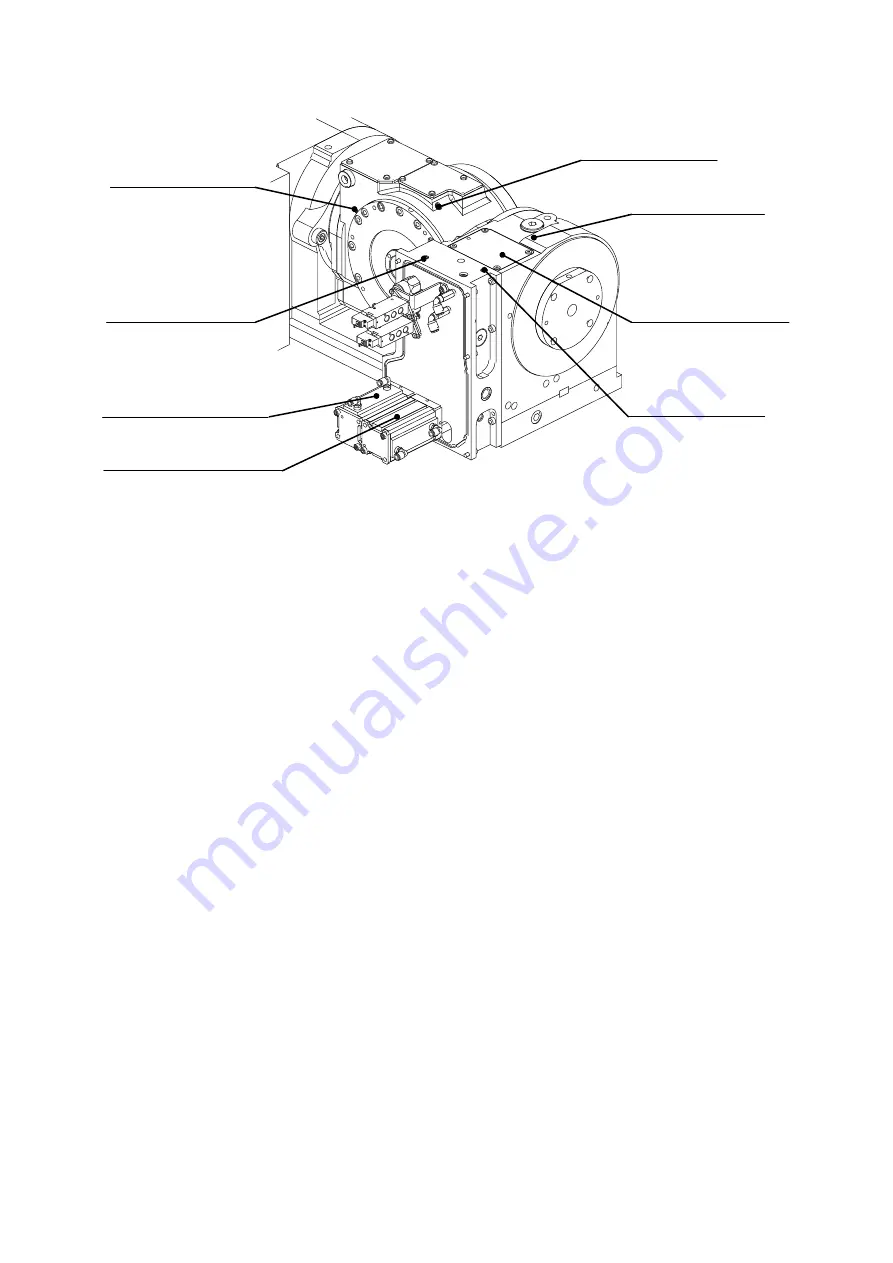

8-3-3. Hydraulic clamp system (See Fig.4)

Tilt the rotating axis 90°from the horizontal state of table (0°) to make the table vertically.

(See Fig.3-1)

Air relief on rotating axis side

Bleed air on the rotating axis side at two points (

①

,

②

).

1) Clamp the NC rotary table (apply hydraulic pressure).

2) Slightly loosen the screw of air relief plug

①

with the table clamped to allow hydraulic oil to leak a little,

so as to bleed the bubbles (air) contained in the leaking oil. After a while, with the table clamped,

tighten the screw of

①

once, and repeat the clamp and unclamp operation. Again, loosen the screw

of

①

to leak the hydraulic oil a little to bleed the bubbles contained in the oil. Repeat this operation

until the bubbles disappear, and tighten the screw of

①

again. Retain lightly the air relief plug

①

with

a hexagonal wrench key, and with the plug covered with rags, loosen the plug a little to bleed the air.

3) When bubbles (air) mixed with oil does not run over the air relief plug

①

, tighten the air relief plug

①

under a clamp state.

4) Then, bleed the air by means of air relief plug

②

by the same procedure.

5) Repeat the procedure until no bubbles are found in the leaking oil even if any screw of air relief plug

①

or

②

is loosened.

Air relief on tilting axis side

Bleed air on the tilting axis side at one point (

③

).

1) Perform the air relief with the air relief plug

③

by the above steps 1) and 2).

2) When bubbles (air) mixed with oil does not run over the air relief plug

③

, tighten the air relief plug

③

under a clamp state.

Fig. 3-3

Air relief plug

④

(Rotating axis)

Air relief plug

③

(Rotating axis)

Air relief plug

⑥

(Tilting axis)

Cover (Oil tank)

①

Air relief plug

②

(Rotating axis)

Air relief plug

⑤

(Tilting axis)

Cylinder for tilting axis

Cylinder for rotating axis