36

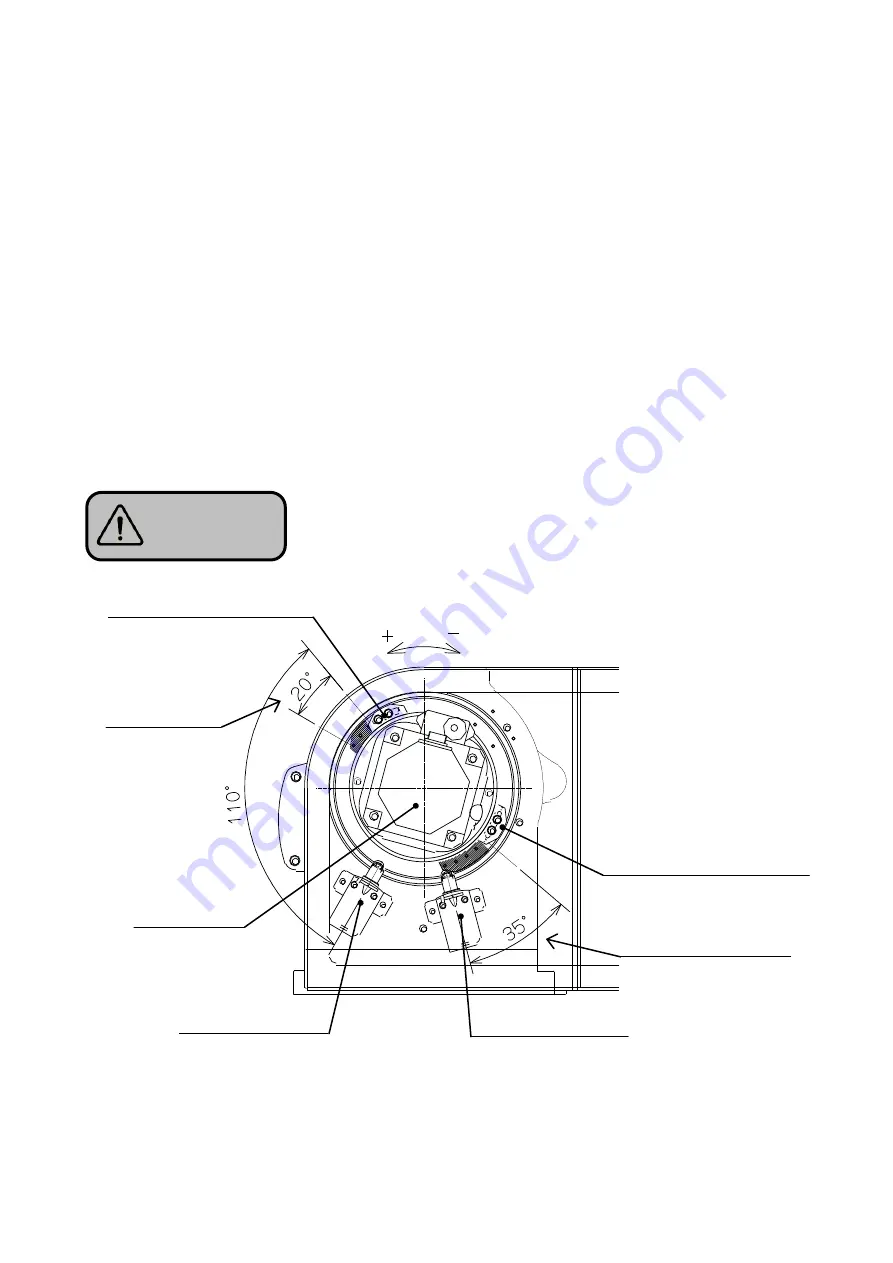

14-3. Adjusting methods of dog for horizontal over-travel

1) When the customer will change position of dog B

②

according to the shape of workpiece and jig,

loosen hexagon socket head cap screw which fix the dog B

②

. Once remove the dog B

②

.

2) Rotate the tilting axis to the tilting angle to be set in the plus direction with the manual pulse

generator or the Manual axis feed key, checking that it does not interfere with the jig or workpiece.

3) After rotating the rotary table to the desired tilting angle, slightly tighten hexagon socket head cap

screws which fix the dog B

②

.

4) Slide the dog B

②

in the reverse direction counterclockwise (CCW) before fixing until the

over-travel alarm lamp lights. Tighten hexagon socket head cap screw that loosened slightly.

5) After fixing the dog B

②

, rotate the tilting axis again with the manual pulse generator or the Manual

axis feed key and check that the tilting axis stops at the desired tilting angle position and alarm lamp

lights.

6) After adjusting, mount the side cover of motor case on the rotating axis side.

When mounting the cover, coat the cover with liquid packing (liquid

gasket 1216 made by THREE BOND) evenly.

CAUTION

Fig.13

Dog A

①

for holiz. (

– side) OT detect

Dog A adjustable range

Limit SW A

③

for holiz.(

– side) OT

Limit SW B

④

for vert.( + side) OT

Dog B

②

for vert. ( + side) OT detect

Dog B

adjustable range

Rotating axis

drive motor