7

The hood comes with plugs suitable for most

walls/ceilings. You should however consult a

qualified technician to make sure the installation is

suitable for your kind of wall/ceiling. The wall/roof

should be sufficiently strong to support the weight

of the hood.

Before installation:

• Check that the product purchased is the right

size for the area where it is to be installed.

• To make installation easier, temporarily remove

the parts that block access to the fixing areas

(e.g.: grease filters, perimetric suction panels

and carbon filter support frames, depending on

which model you have).

• Remove the active carbon filter/s if provided

(again consult relative paragraph). This/these

should be re-assembled only if you wish to use

the hood in the extraction mode.

• Check that there are no parts (e.g. bags with

screws, warranty) inside of the hood (for

transport reasons). If there are, remove them

and put to the side.

• If possible, disconnect and remove the

surrounding units and those near the installation

area of the hood so that you have better

accessibility to the ceiling / wall where the hood

is to be installed. Otherwise, protect the units

as much as possible and all the parts relating to

the installation. Choose a flat surface and cover

it with some protection where you can place

the hood and parts.

• Furthermore, check that near the area where

you are installing the hood (in an area accessible

even when the hood is fitted) there is an

electric socket and that you can connect to an

venting pipe to the outside (In the Vented

mode only).

• Disconnect the electrical power from the

electrical socket connected to the hood at the

main switchboard and remember not to

connect the hood to the mains supply before

completing installation.

• Carry out all the building work necessary (e.g.:

installation of an electrical plug and/or holes to

pass the exhaust venting pipe through).

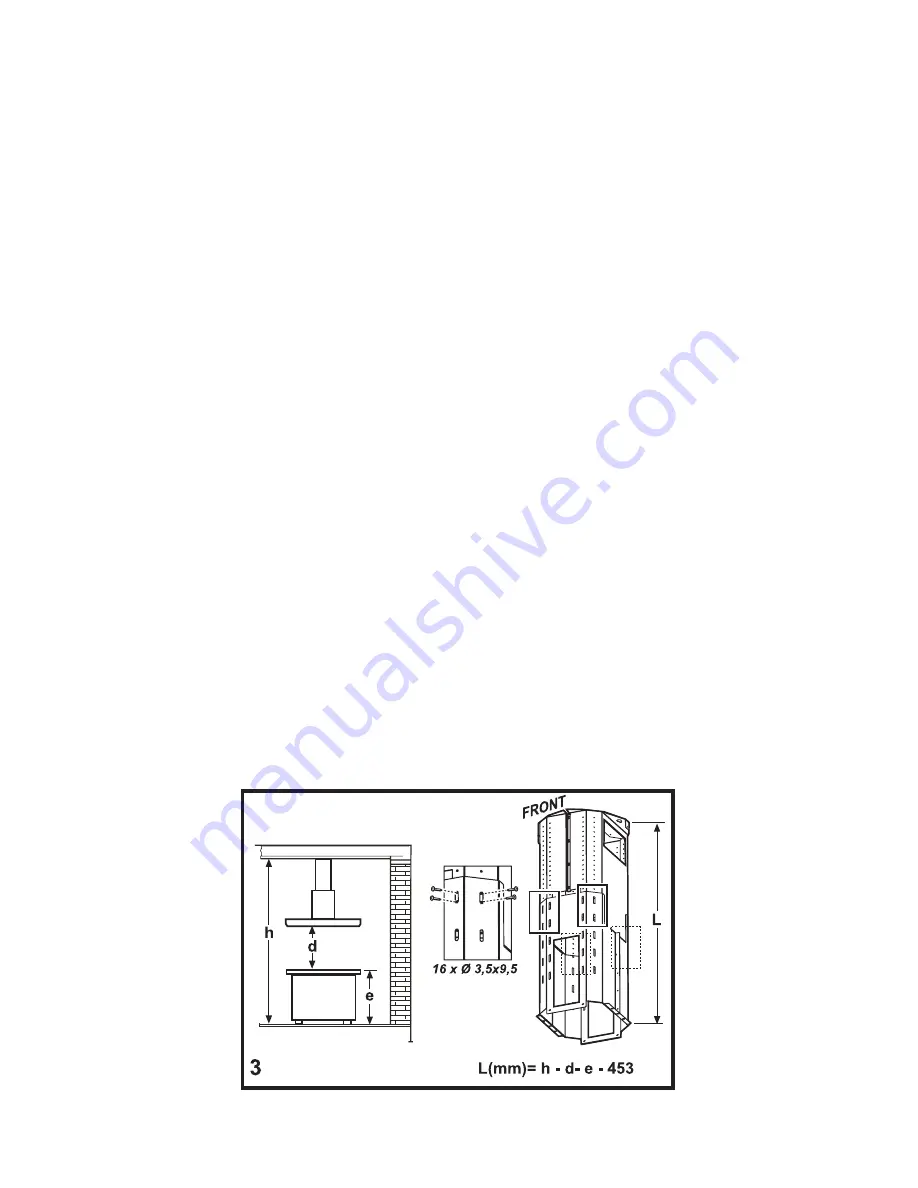

Fig. 3

• Establish the most suitable distance from the

work surfaces according to your needs

(Important! Respect the minimum distances

specifically indicated in this instruction booklet).

• Adjust the extension of the hood’s support

structure using the mathematical formula shown

in the diagram.

Note:

only if you wish to use the hood in

recirculation mode (see also fig. 4 and later

paragraphs): in the case of highly extended

structures, before final assembly remember to

install the deflector so that it will be easier to

handle.

• Fit the two sections of the structure with a total

of 16 screws (8 per side).

Installation

Summary of Contents for KCIP 1010/I

Page 1: ...KCIP 1010 I KCIP 1210 I Instructions for use ...

Page 2: ......

Page 11: ...Brown Blue 11 Installation ...

Page 19: ......