10 SINGLE MODELS ONLY

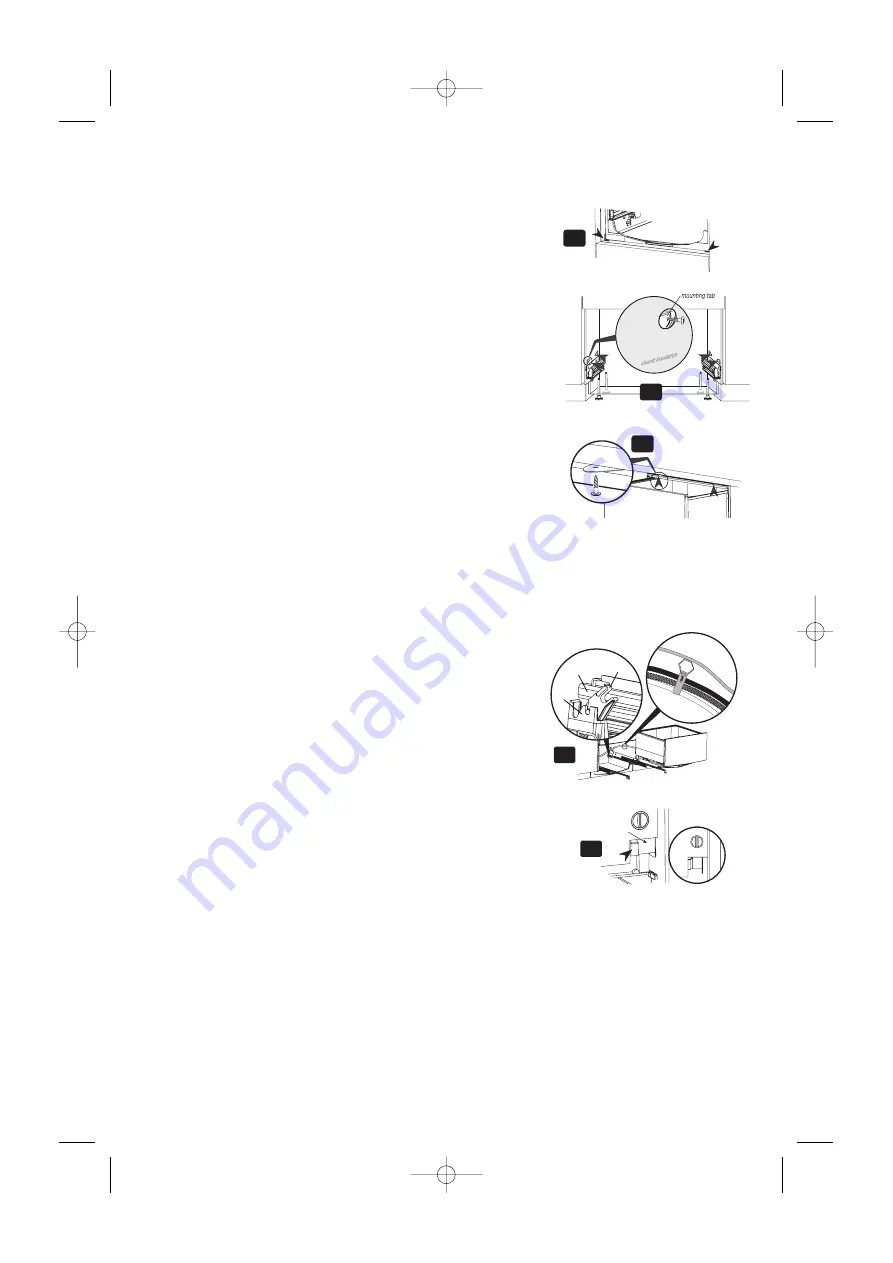

Check the position of the chassis is still where marked on the

cavity, before securing the product.

11

There are four 16mm round holes, two on the left and two on the

right hand side in the sound insulation. These provide access to

the mounting tabs.

To secure the product to the cabinetry use a 16mm Phillips screw

in each mounting tab.

Make sure the sound insulation is positioned correctly before

continuing installation.

12

Screw the two top tabs to the underside of bench. Use the

supplied Phillips 16mm screws. Tabs can accommodate a

maximum of 19mm vertical gap.

Step 4: securing the product

10

11

12

17

Important!

Before refitting the tub, ensure the hoses are not twisted and

the latches at the rear of each drawer runner are facing

forward.

13

To refit the tub, make sure both of the latches at the rear of each

drawer runner are facing forward. Ensure hoses are hooping

upward. Place the tub on the half open drawer runners and close

the drawer.

14

Check the tub clips have reset on both sides of the tub. If not, pull

the tub clips forward until the tub clip button is reset.

Important!

Ensure the tub clips on both sides are reset.

Step 5: refitting the tub

13

14

Latch

Drawer

Runner

Latch

Bracket

TUB CLIP

INCORRECT

5019_102_00273_INSTAL_GB 30-05-2007 13:25 Pagina 17

Summary of Contents for KDDD 6010

Page 1: ...KDDS 6010 KDDD 6010 Assembly instructions 5019_102_00273_INSTAL_GB 30 05 2007 13 25 Pagina 1 ...

Page 2: ...5019_102_00273_INSTAL_GB 30 05 2007 13 25 Pagina 2 ...

Page 22: ...5019_102_00273_INSTAL_GB 30 05 2007 13 25 Pagina 22 ...

Page 23: ...5019_102_00273_INSTAL_GB 30 05 2007 13 25 Pagina 23 ...