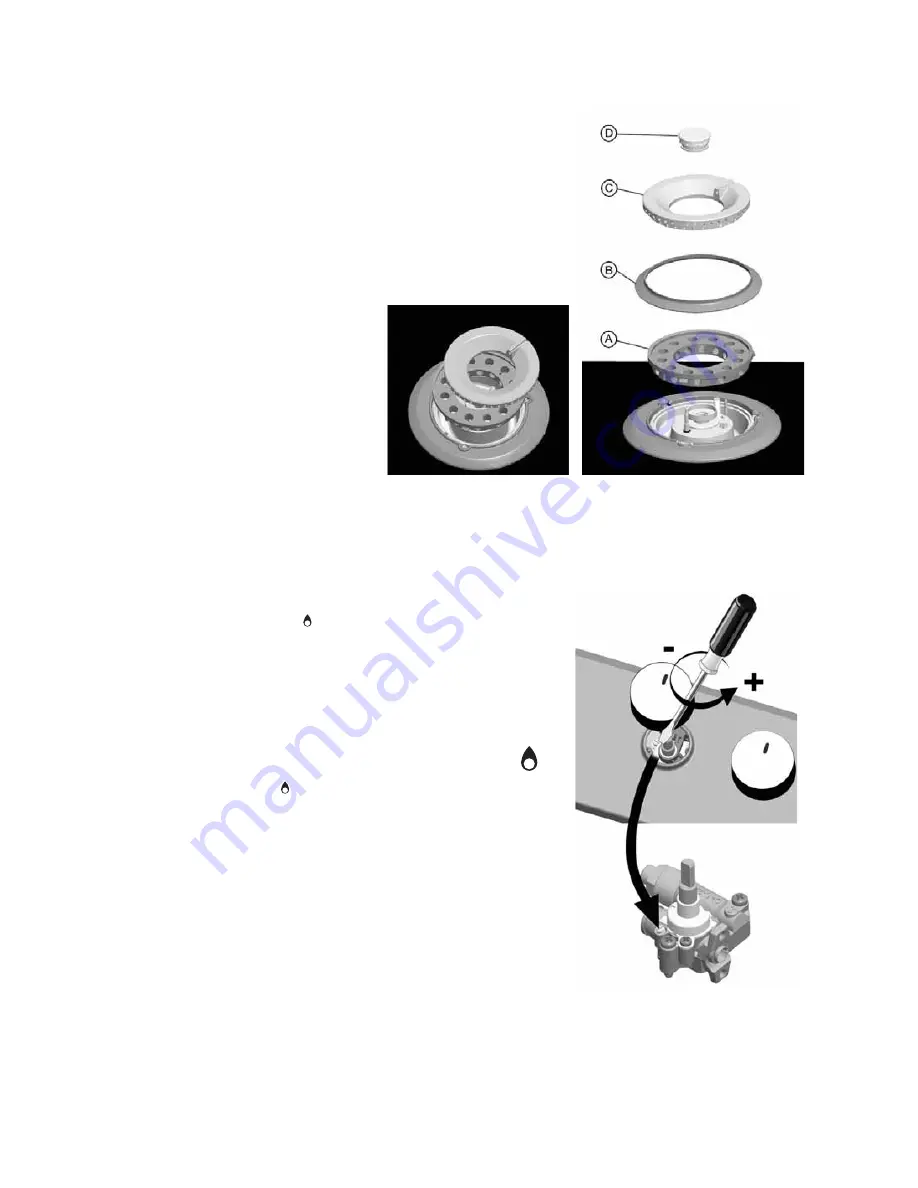

To fit the double crown wok burner:

Insert in the following order:

1. burner ring (A);

2. decorative covering ring (B);

3. external burner cap (C);

4. internal burner cap (D).

Note: make sure that:

1. the locating pin for the burner ring (A) is inserted correctly in the

slot on the burner unit.

2. that the locating pin on the external

burner cap (C) is inserted in the slot

on the burner ring (A).

Fitting the wok burner

Regulating the minimum flow level must be done with the tap at the

lowest position (small flame)

.

There is no need to regulate the primary air in the burners.

To ensure the minimum level is properly regulated, remove the

control knob and adjust the screws found on the tap as follows:

1. tighten to reduce the height of the flame 1 (-)

2. slacken to increase the height of the flame (+);

3. With the burners on, rotate the buttons from the maximum

to

the minimum position

to check the stability of the flame.

Once you have finished regulating, close up the seals again using

sealing wax.

Regulating the minimum flow level of the gas taps

13

Summary of Contents for KHPF 9010

Page 1: ...KHPF 9010 KHPS 9010 ...

Page 2: ......